Prefabricated laminated slab suitable for laying floor heating pipeline and preparation process

A floor heating pipe and preparation technology, which is applied in the direction of manufacturing tools, floor slabs, building components, etc., can solve the problems that the pins on the laminated slab surface are easily broken, the labor and material consumption is large, and the insertion depth cannot be guaranteed, so as to shorten the laying and binding Time, improve production and processing efficiency, ensure the effect of production and processing feasibility and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

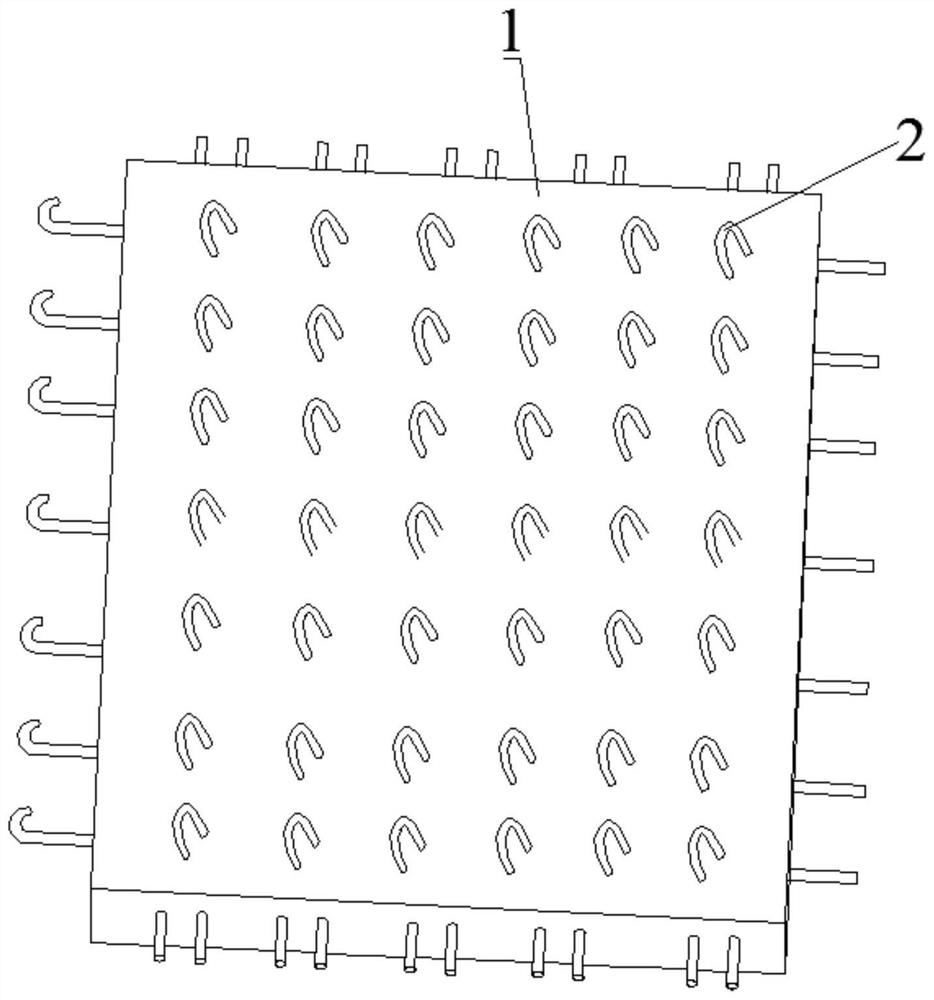

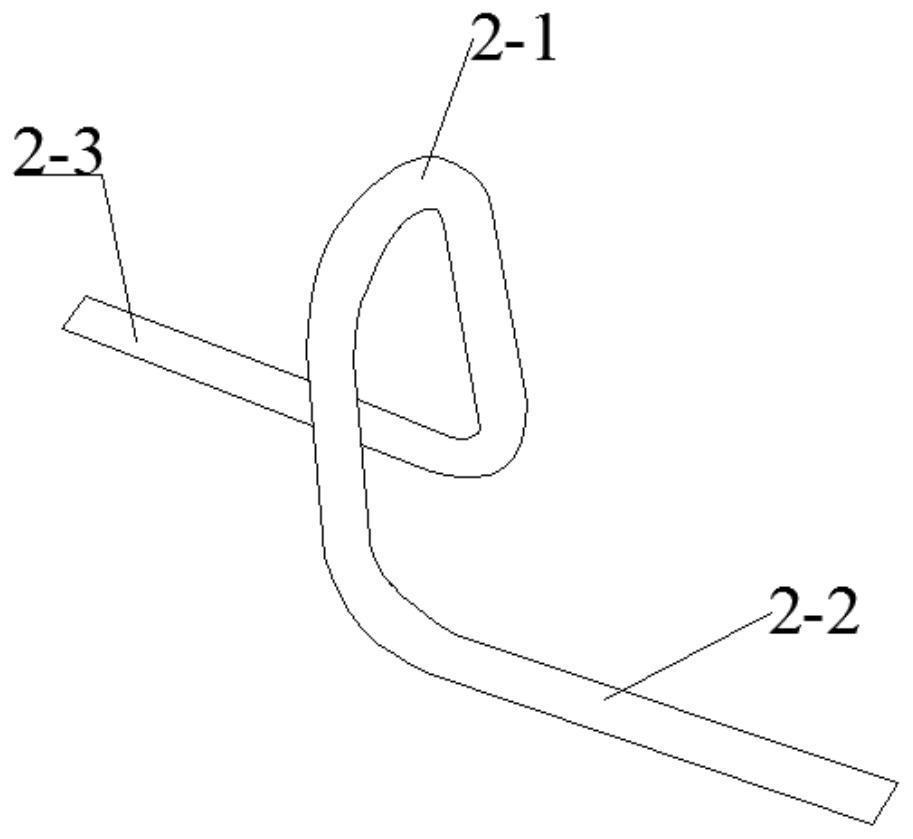

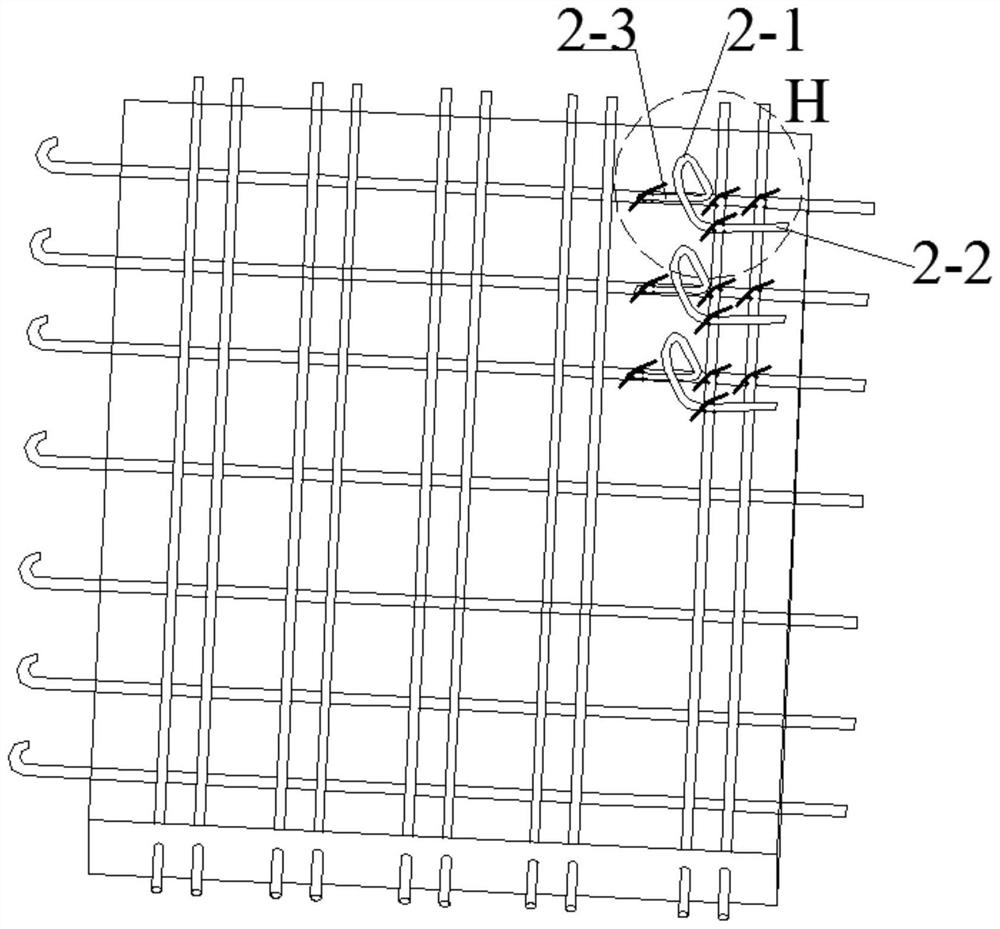

[0038] Such as Figure 1~4 As shown, the present invention is a prefabricated laminated slab suitable for laying floor heating pipelines, including a concrete slab 1, the upper end of the concrete slab 1 is provided with several stirrup bars 2 at intervals, and several stirrup bars 2 are arranged in a matrix , the stirrup bar 2 includes an "n"-shaped bar 2-1, and one end of the "n"-shaped bar 2-1 is provided with a first Outrigger 2-2, the other end of the "n"-shaped bar 2-1 is provided with a second outrigger 2-3 facing the other side of the "n"-shaped bar 2-1, the said The lower ends of the first leg 2-2, the second leg 2-3 and the "n" type rod 2-1 are pre-buried and poured inside the concrete slab 1, and the upper end of the "n" type rod 2-1 Vertically located above the concrete slab 1 .

[0039] Preferably, both the first leg 2-2 and the second leg 2-3 are perpendicular to the plane where the "n"-shaped rod 2-1 is located.

[0040] Further preferably, the distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com