Annular packing valve and completion pipe string

An annulus and isolation valve technology, applied in sealing/isolation, wellbore/well components, wellbore/well valve devices, etc., can solve problems such as failure to open oil production channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

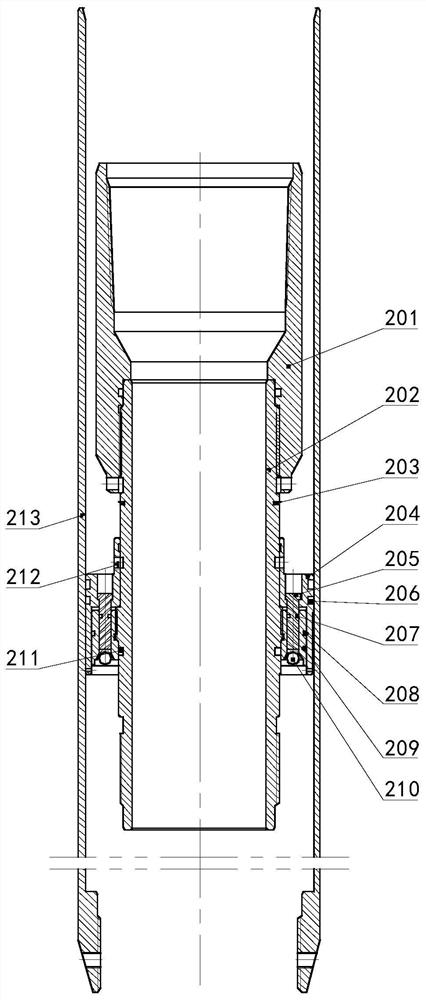

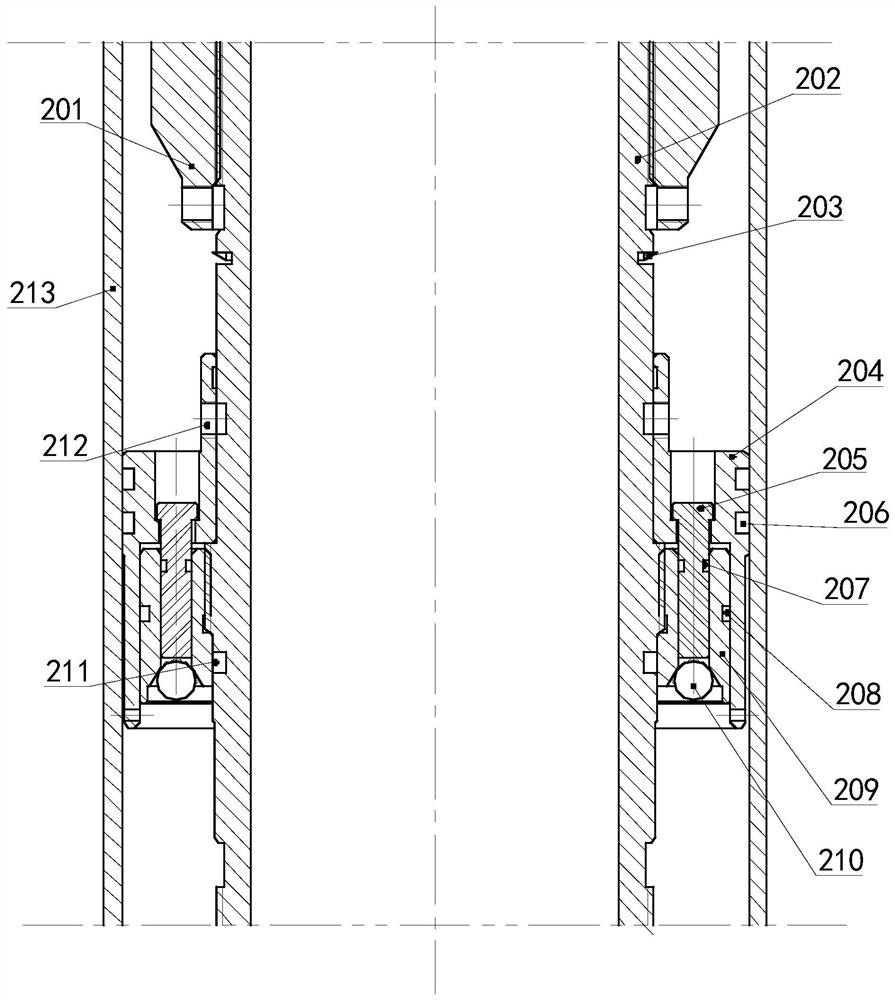

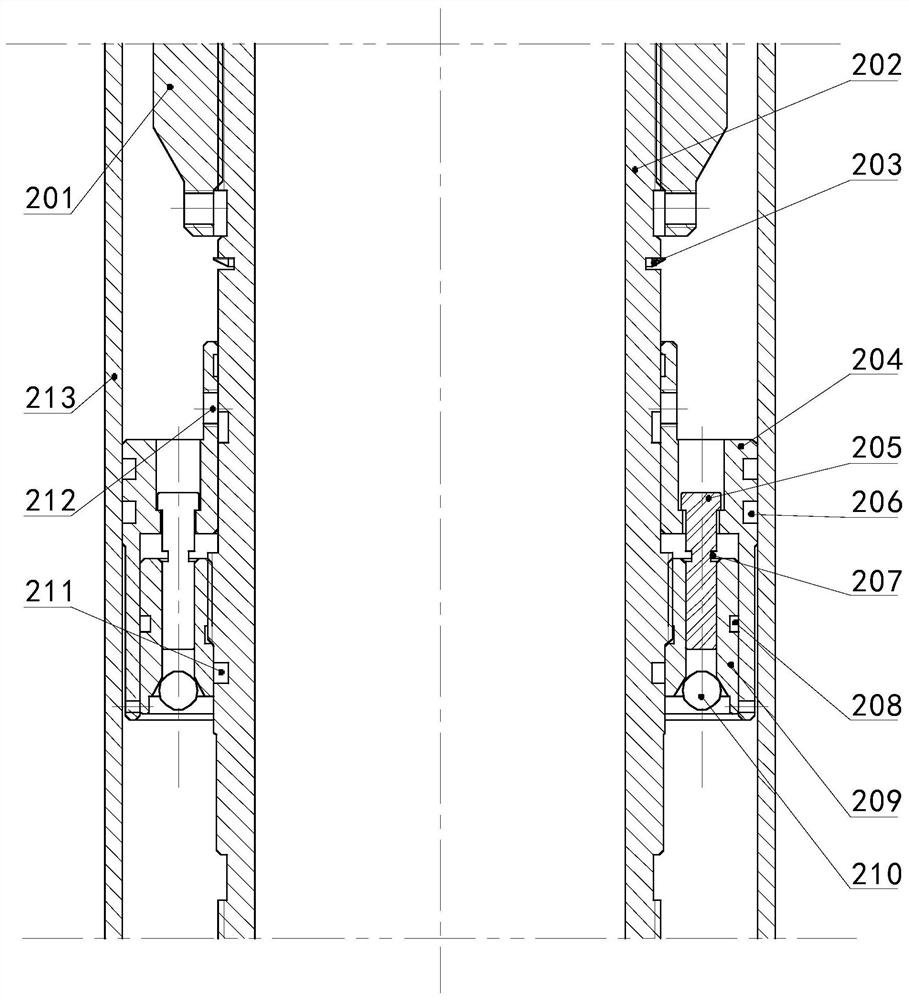

[0082] Such as Figure 1-Figure 4 As shown, the annulus isolation valve 200 provided in this embodiment includes a first central pipe 202, a first sealing seat 209, a first sealing body 210 and a first piston, and the first sealing seat 209 is fixed to the first central pipe 202 connection, the first piston is connected to the first central tube 202 in a destructible manner through a seal maintaining member, the first piston and the first sealing seat 209 are located on the outside of the first central tube 202, and the first piston is located on the first sealing seat 209 Above, the first sealing body 210 is located below the first sealing seat 209, and the first piston is also provided with a suction part 205;

[0083] When the first piston and the first central tube 202 are fixedly arranged, the first piston is used to receive the first upward force of the first liquid located below the first sealing seat 209, and the suction part 205 applies an upward force to the first se...

Embodiment 2

[0108] Such as Figure 5 As shown, the completion string provided in this embodiment includes the annulus isolation valve 200 in the first embodiment described above.

[0109] Since the completion string provided in this aspect includes any one of the above-mentioned annulus isolation valves 200 , it has the technical effect of any one of the above-mentioned annulus isolation valves 200 , which will not be repeated here.

[0110] The completion string also includes a first outer sheath 213, a screen unit 100 and a water control unit 300. The screen unit 100 is connected to the first central pipe 202 through the first upper joint 201, and the water control unit 300 is connected to the first central pipe. 202 is connected to the external thread at the lower end, and the first outer sheath 213 is arranged on the outside of the annulus isolation valve 200 .

[0111] Specifically, refer to Figure 1-Figure 5 , the action principle of this embodiment is as follows:

[0112] Conne...

Embodiment 3

[0116] Such as Figure 6-Figure 10 As shown, the differences between this embodiment and Embodiment 1 are:

[0117] The annulus isolation valve of this embodiment includes a second central pipe 402, and the sealing member includes a second piston 403. The second piston 403 is fixedly connected to the second central pipe 402 through a seal maintaining member in a destructible manner. The second piston 403 Located on the outside of the second central tube 402, when the second piston 403 and the second central tube 402 are fixedly arranged, the second piston 403 isolates the space above the second piston 403 from the space below the second piston 403, and the second piston 403 for receiving the first upward force from the first liquid located below the second piston 403;

[0118] The sealing control assembly includes an unlocking assembly, the unlocking assembly includes a locking body 405 and an unlocking driver 406, the locking body 405 is connected to the second piston 403 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com