Fan blade deicing device

A technology for fan blades and blades, applied in the field of fan blade deicing devices, can solve the problems of low efficiency, difficult maintenance, high energy consumption, etc., and achieve the effects of low cost, delayed icing, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

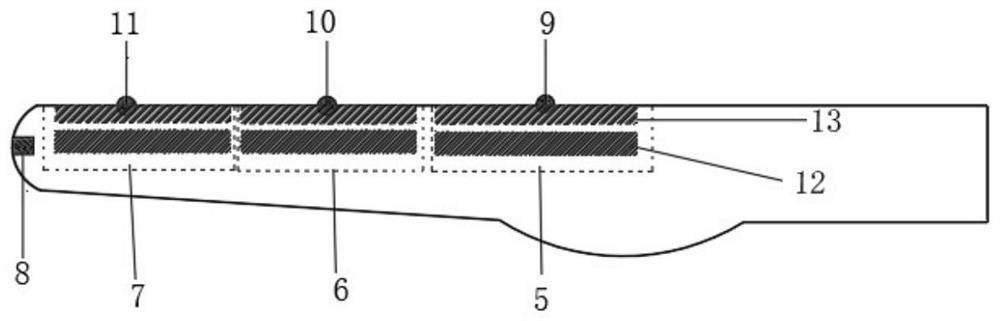

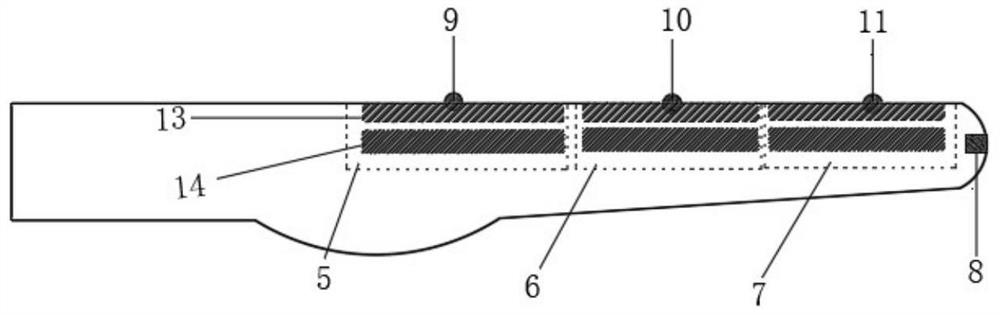

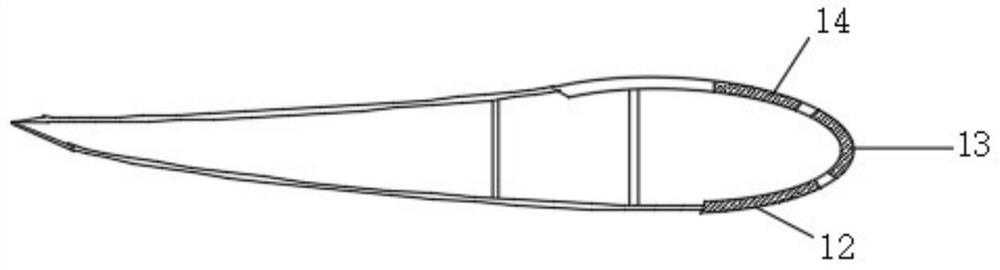

[0036] Embodiment 1: as Figure 1-7As shown, a fan blade deicing device includes a deicing system control cabinet, an external sensor detection device, a ceramic electrothermal film 3 and a nanometer super-hydrophobic coating 1 coated on the outer surface of the fan blade; the deicing system control cabinet adopts PLC controller, the external sensing and detecting device includes an icing sensor and a temperature sensor, and the external sensing and detecting device is connected to the control cabinet of the deicing system; the fan blade is divided into electrothermal film area I5 and electrothermal film area I5 sequentially from the blade root to the blade tip. Area Ⅱ6 and electrothermal film area Ⅲ7, electrothermal film area Ⅰ5, electrothermal film area Ⅱ6 and electrothermal film area Ⅲ7 are respectively equipped with icing sensor Ⅰ9, icing sensor Ⅱ10 and icing sensor Ⅲ11 for real-time monitoring of the temperature of each divided area on the fan blade. The icing situation i...

Embodiment 2

[0052] Embodiment 2, a fan blade deicing device, such as figure 1 , figure 2 As shown, the present invention divides the electric heating of the blade into zones according to the severity of icing in each area of the blade and the power limitation of the conductive slip ring. The fan blade is divided into electrothermal film area I5 (area 1), The electric heating film area Ⅱ6 (area 2) and the electric heating film area Ⅲ7 (area 3), the electric heating film area Ⅰ5, the electric heating film area Ⅱ6 and the electric heating film area Ⅲ7 are equipped with icing sensor Ⅰ9, icing sensor Ⅱ10 and icing sensor Ⅲ11 respectively To monitor the icing situation in each divided area on the fan blades in real time and feed back to the deicing system control cabinet. The icing sensor set uses the blade icing sensor Model 9734-SYSTEM to monitor the icing situation in real time and feed back to the deicing system The control cabinet is equipped with a temperature sensor 8 outside the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com