Cooling hub structure and cooling fan formed by same

A technology for cooling fans and hubs is applied in the components of pumping devices for elastic fluids, non-variable-capacity pumps, pump devices, etc., and can solve problems such as cost increase, impact on motor performance and life, and motor temperature rise. Achieve the effect of reducing impact, improving heat exchange efficiency, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

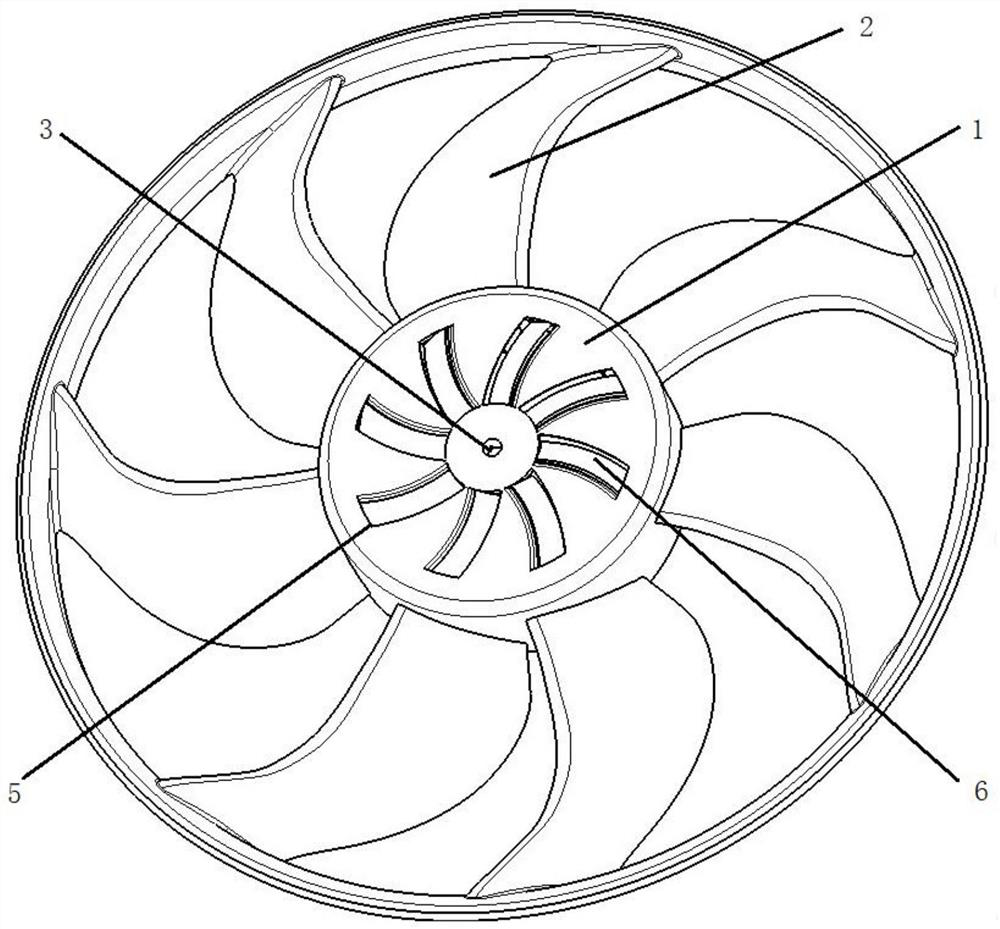

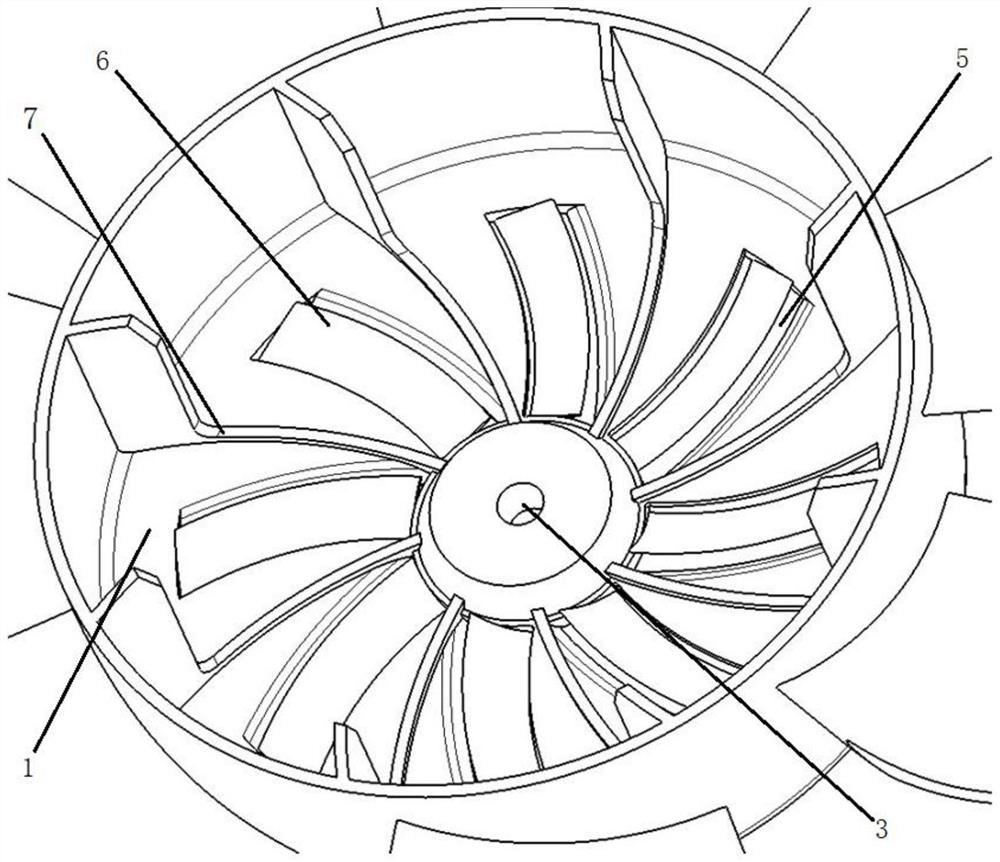

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

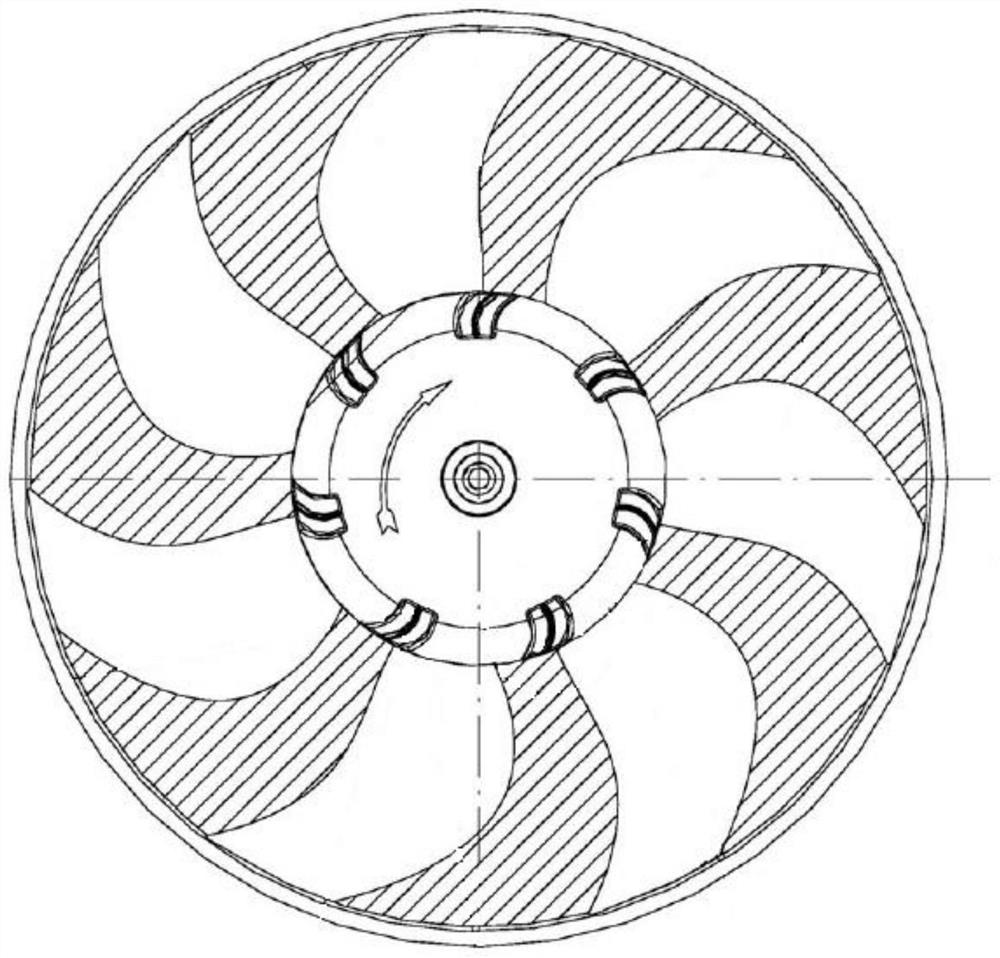

[0031] Patent No. CN207621075U discloses a motor fan heat dissipation hub structure and the cooling fan formed thereof, such as figure 1 As shown, the fan hub is provided with several ventilation slots along the edge, and the fan hub is provided with ventilation holes. The ventilation slots communicate with the motor housing cavity through the ventilation holes, so that the heat inside the motor body is discharged to the outside air under the air flow.

[0032] However, the ventilation holes of the hub of the above-mentioned fan are arranged along the edge of the hub, the area of the hole is small, and the capacity for entering gas is small, and it is a hollow projection structure on the projection plane perpendicu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com