Method for evaluating selective adsorption of rubber powder to asphalt components and molecular groups

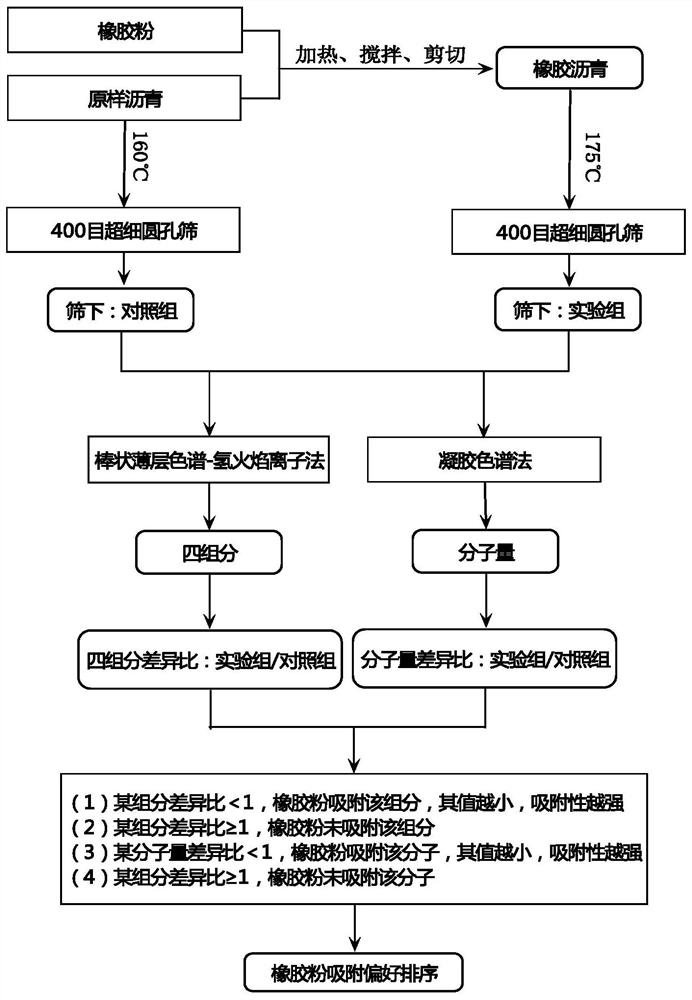

An evaluation method, the technology of rubber asphalt, applied in the direction of material separation, analysis of materials, preparation of test samples, etc., can solve the problem that it is difficult to quantitatively reveal the adsorption preference of rubber powder to asphalt components, cannot reflect the selective absorption of asphalt components, rubber Problems such as powder particle filtration and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Select No. 70 matrix asphalt sample, weigh 500g of the original asphalt, place it in a container and heat it to 160°C, select 20 mesh rubber powder (source A), use 20% of the dosage, add the rubber powder In asphalt, after high-speed shearing at a rate of 5000rpm for 60 minutes, swelling and development for 30 minutes to prepare rubber asphalt;

[0031] (2) Weigh 100g of the original asphalt and rubber asphalt respectively, heat the original asphalt to 160°C, and heat the rubber asphalt to 175°C, and maintain the temperature, put the two kinds of asphalt into ultra-fine round hole sieves (400 mesh, Stainless steel material), make it filter and elute under natural gravity for 24 hours to ensure that there is no free asphalt on the surface of the rubber particles in the experimental group; collect the asphalt under the sieve and weigh it to be tested, the original asphalt under the sieve is the control group, and the rubber asphalt under the sieve is the experiment Gr...

Embodiment 2

[0057] (1) Select No. 90 matrix asphalt sample, weigh 500g of the original asphalt, place it in a container and heat it to 160°C, select 40 mesh rubber powder (source B), use 50% of the dosage, add the rubber powder In asphalt, after high-speed shearing at a rate of 5000rpm for 60 minutes, swelling and development for 30 minutes to prepare rubber asphalt;

[0058] (2) Weigh 100g of original asphalt and rubber asphalt respectively, heat the original asphalt to 160°C, and rubber asphalt to 175°C, and maintain the temperature, place the two kinds of asphalt on a 400-mesh ultra-fine round hole sieve for gravity Filter and elute for 24 hours to ensure that there is no free asphalt on the surface of the rubber particles in the experimental group; collect the asphalt under the sieve and weigh it to be tested, the under-sieve of the original asphalt is the control group, and the under-sieve of the rubber asphalt is the experimental group;

[0059] (3) Take 10 mg of asphalt from the co...

Embodiment 3

[0086] Using the same method as in Examples 1 and 2, the difference is that the base asphalt sample in the step (1) is No. 50, and the rubber powder is 60 mesh (source C). Adopt asphalt four-component difference ratio and molecular weight difference ratio result of the present invention as shown in table 9 and 10:

[0087] Table 9 Difference ratio of four components of asphalt of the present invention

[0088] four components Saturation Aroma colloid Asphaltenes Component difference ratio / % 1.16 0.98 0.88 1.31

[0089] According to Table 9, according to the aforementioned evaluation criteria, it can be seen that:

[0090] ① The difference ratio of aromatic components is 0.99<1, indicating that the rubber powder in the experimental group has absorbed the aromatic components, and it is believed that the rubber powder has a preference for the absorption of aromatic components; the difference ratio of the colloidal components is 0.88<1, indicating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com