Full-prefabricated non-destructive disassembly and assembly type decoration construction method

A construction method and prefabricated technology, applied in the field of prefabricated and non-destructive disassembly of prefabricated decoration construction, can solve the problems of low collision coordination processing efficiency, poor collaborative operation, poor operator efficiency, etc., and achieve easy renovation or maintenance. Difficulty and ease of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

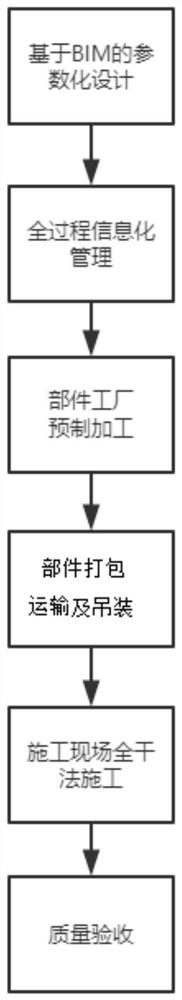

[0019] Such as figure 1 Shown is a fully prefabricated non-destructive disassembly design and construction method for prefabricated decoration, the method includes the following steps:

[0020] Step 1. BIM-based decoration design: build a 3D BIM model of the decoration construction site, and carry out decoration design in the model, including the underlying structure design and shape layout design; use the built-in model product library to automatically disassemble the decoration design Divide, and code each part after splitting to generate a parts list.

[0021] For the establishment of the original model, scan the construction site through a 3D scanner, automatically generate a 3D BIM model, and carry out decoration design in the model, mainly including:

[0022] 1. Partition wall design:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com