A molding die for an e-shaped magnetic core and a processing and molding method thereof

A technology for forming molds and processing and forming, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., and can solve the problems of damage to the core body, increased product defect rate, and inconvenient demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

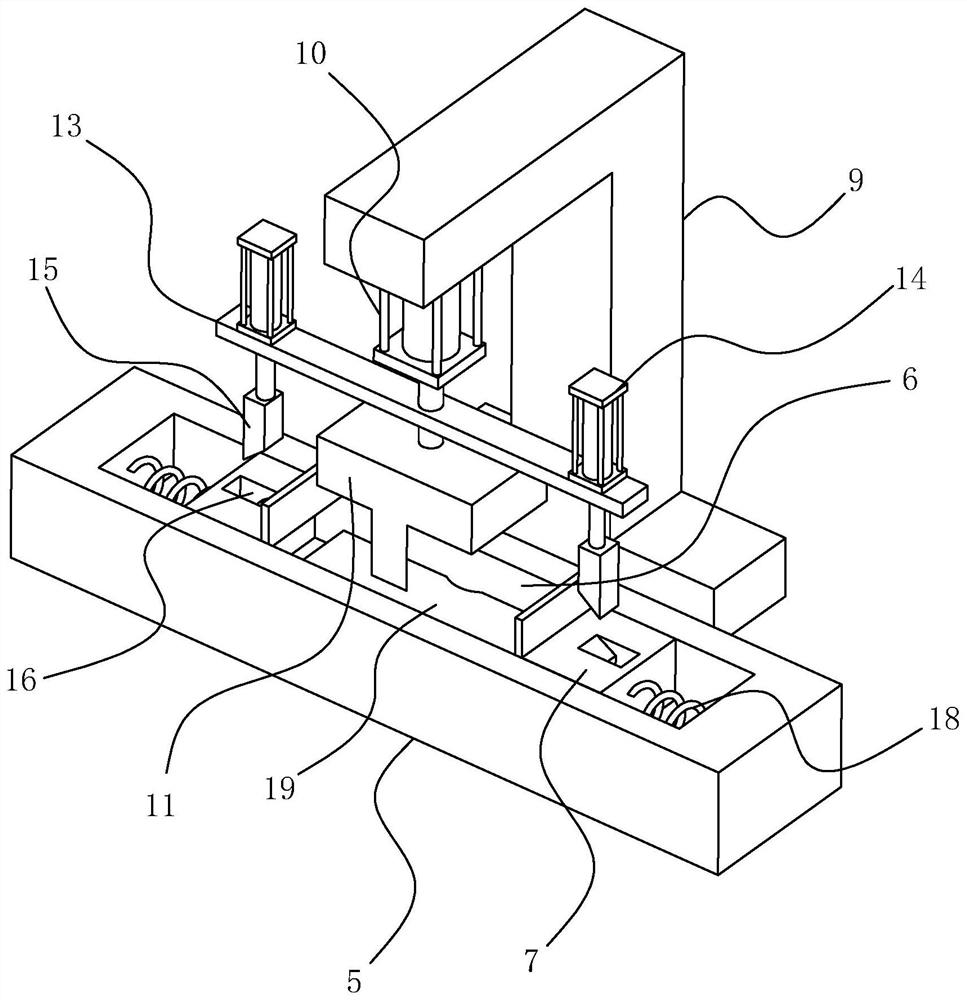

[0035] refer to Figure 1 to Figure 7 The embodiments of the present invention will be further described.

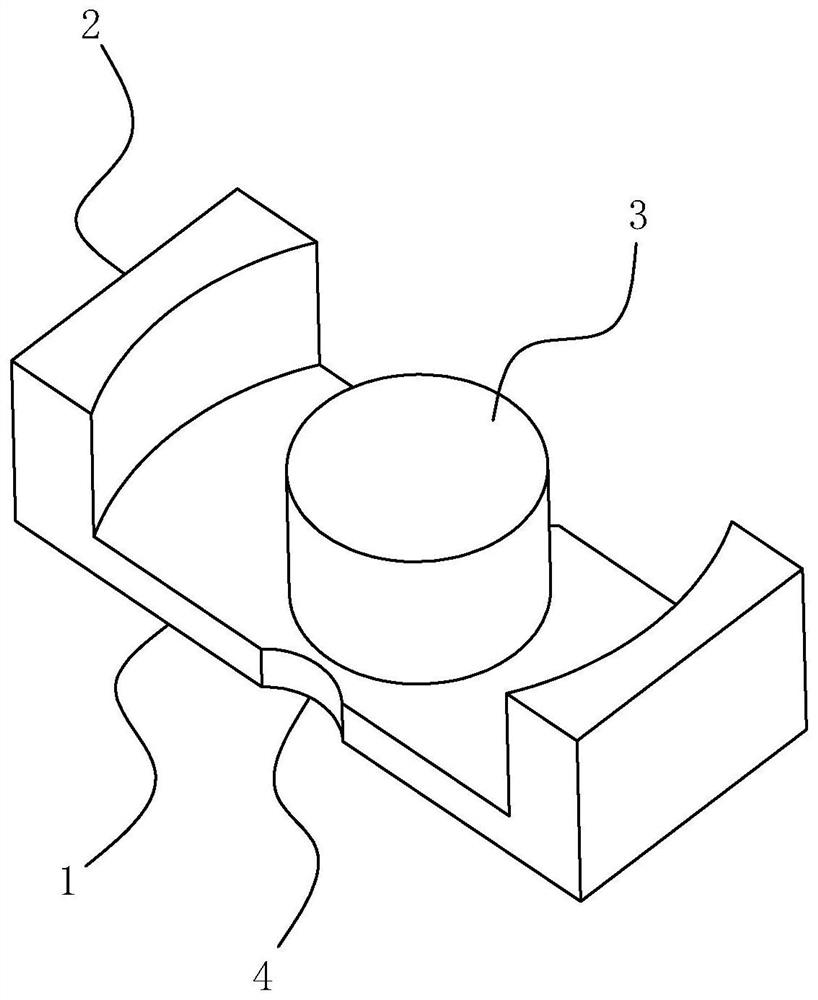

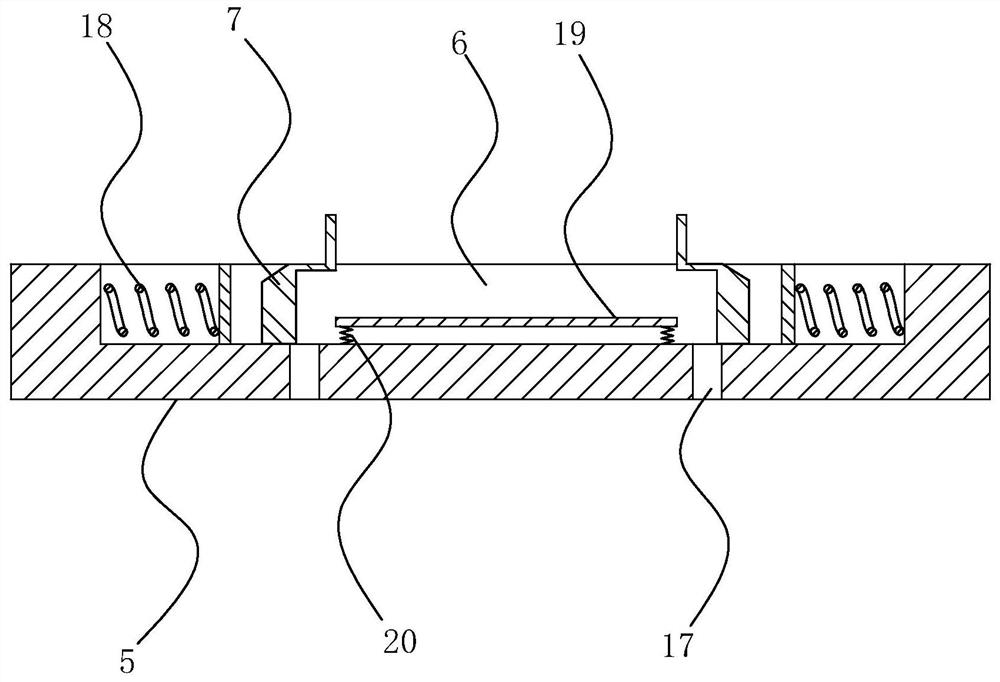

[0036] A molding die for an E-shaped magnetic core. The E-shaped magnetic core includes a base plate 1, side plates 2 fixedly connected to both ends of the surface of the base plate 1, and a central column 3 fixedly connected to the middle of the surface of the base plate. The base plate is located on both sides of the central column 3. Groove 4 is arranged, and this forming mold comprises lower mold 5, and the upper surface of lower mold 5 is provided with forming cavity 6, and the two sides in forming cavity 6 are slidably connected with two slide blocks 7, and the opposite side wall of slide block 7 The top is fixedly connected with a horizontal fixed plate 8, the width of the sliding block 7 and the width of the fixed plate 8 are equal to the width of the molding cavity 6, and a pressing device is arranged directly above the lower mold 5, and the pressing device incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com