Motor control method, device, terminal device and storage medium

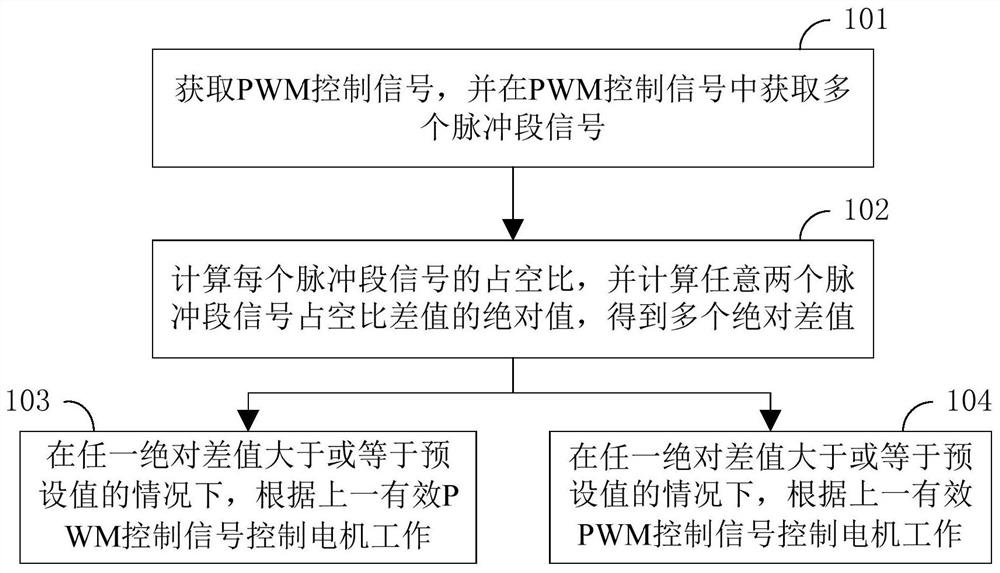

A motor control and control signal technology, which is applied in the direction of AC motor control, motor vibration suppression control, control system, etc., can solve the problem that the PWM control signal affects the motor control accuracy, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

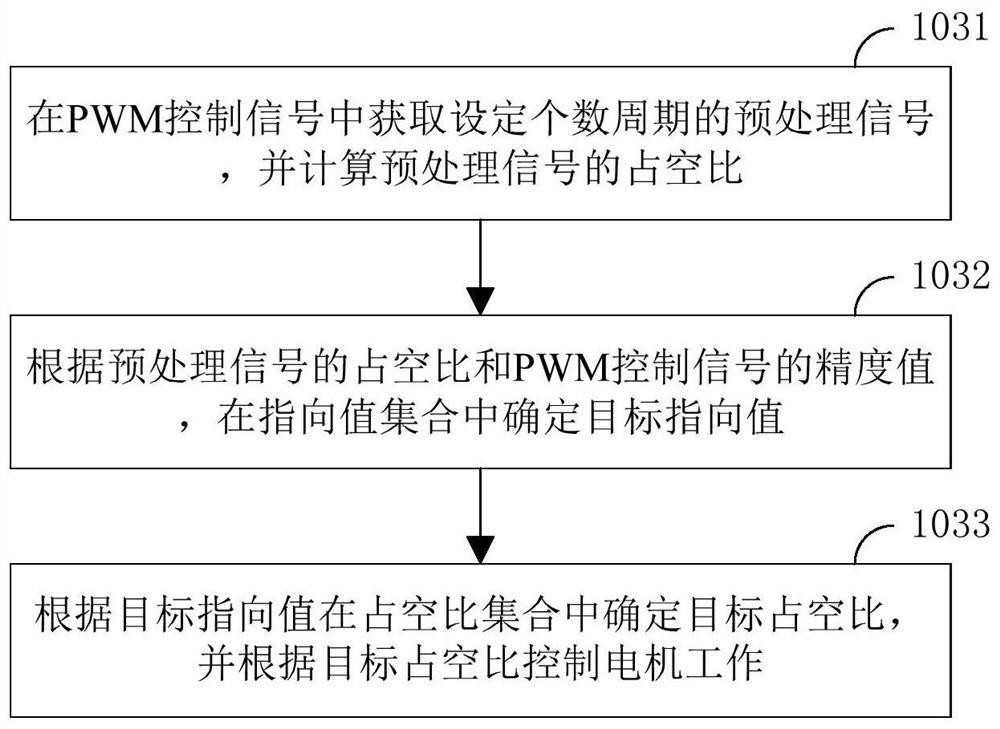

Method used

Image

Examples

Embodiment 1

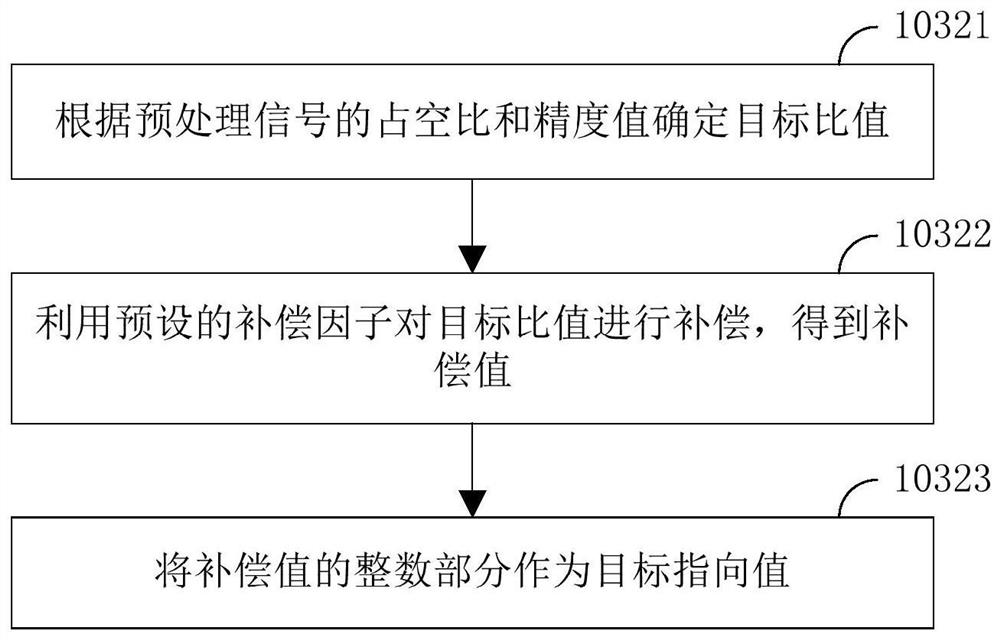

[0099] The precision value of the PWM control signal is 1%, the duty cycle of the PWM control signal input at the current time is 35%, the duty cycle of the acquired preprocessing signal is 35.3%, and the compensation factor is 0.5. Since the precision value of the PWM control signal is 1%, the duty cycle set can be obtained as {0, 1%, 2%, 3%, ..., 100%}, and the preset pointing value set is {0, 1, 2, 3, ..., 100}.

[0100] The compensation value m is:

[0101]

[0102] Then the target pointing value M=35, the M+1th pointing value in the pointing value set is 36, and the duty cycle associated with 36 in the duty cycle set is 35%, then the target duty cycle is 35%, which is the same as the input PWM The duty cycle of the control signal is the same.

[0103] If the ordinary control method is used, the motor will be controlled by the PWM control signal with a duty cycle of 35.3%. After using this method, the duty cycle of the control motor operating signal is the duty cycle ...

Embodiment 2

[0105] The precision value of the PWM control signal is 2%, the duty cycle of the PWM control signal input at the current time is 36%, the duty cycle of the acquired preprocessing signal is 36.3%, and the compensation factor is 0.5. Since the precision value of the PWM control signal is 2%, the duty cycle set can be obtained as {0, 2%, 4%, 6%, ..., 100%}, and the preset pointing value set is {0, 1, 2, 3, ..., 50}.

[0106] The compensation value m is:

[0107]

[0108] Then the target pointing value M=18, the M+1th pointing value in the pointing value set is 19, and the duty cycle associated with 19 in the duty cycle set is 36%, then the target duty cycle is 36%, which is the same as the input PWM The duty cycle of the control signal is the same.

[0109] If the ordinary control method is used, the motor will be controlled by the PWM control signal with a duty cycle of 36.3%. After using this method, the duty cycle of the control motor operating signal is the duty cycle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com