Device and method for parallel control of lasers and laser marking machine

A parallel control, laser technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as low printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

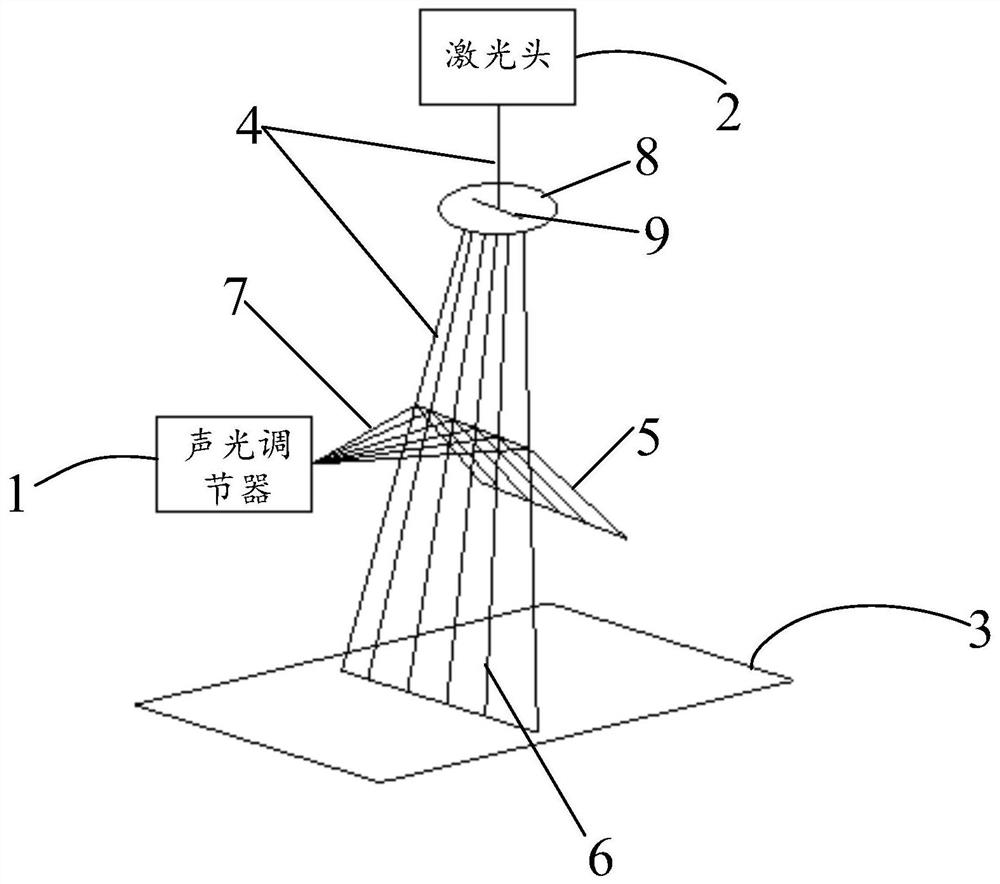

[0033] Such as figure 1 As shown, a parallel laser control device according to an embodiment of the present invention includes an acousto-optic modulator 1 and a laser head 2;

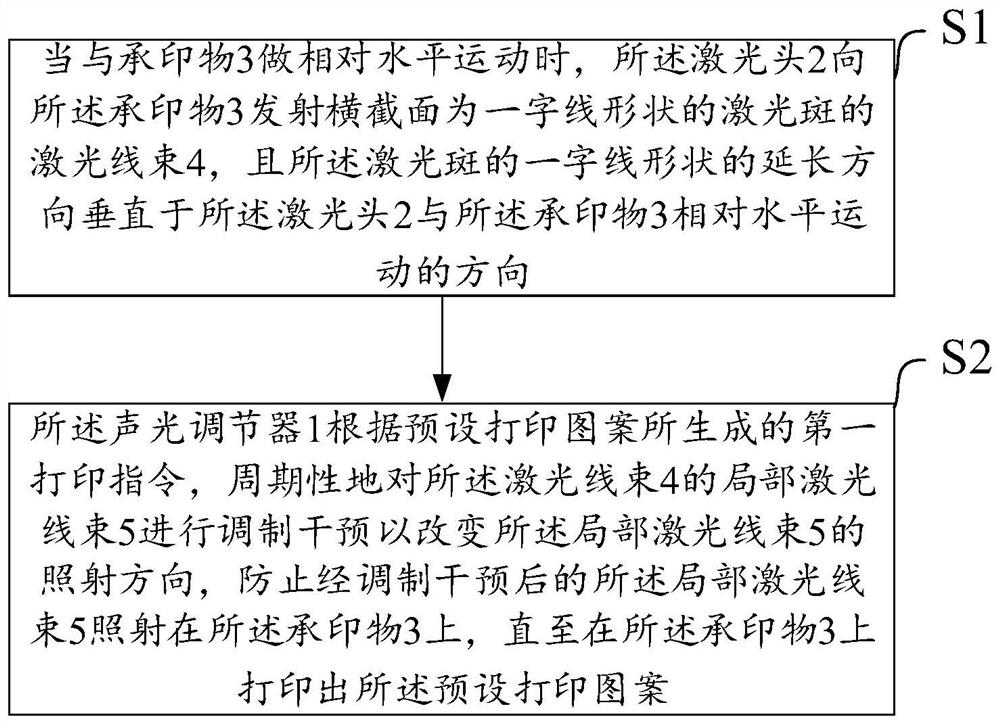

[0034] The laser head 2 is used to emit a laser beam 4 with a cross-section of a laser spot in the shape of a line to the substrate 3 when it moves relatively horizontally with the substrate 3, and the shape of the laser spot is in the shape of a line The extension direction is perpendicular to the relative horizontal movement direction of the laser head 2 and the substrate 3;

[0035] The acousto-optic modulator 1 is used for periodically modulating the local laser beam 5 of the laser beam 4 according to the first printing instruction generated by the preset printing pattern to change the local laser beam 5 The irradiation direction prevents the modulated intervening partial laser beam 5 from irradiating the substrate 3 until the preset printing pattern is printed on the substrate 3 .

[0036] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com