Foundation reinforcement treatment method

A technology of foundation reinforcement and treatment method, which is applied in the fields of foundation structure engineering, field foundation soil survey, soil protection, etc. Strengthen the effect of reinforcement quality and bearing capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

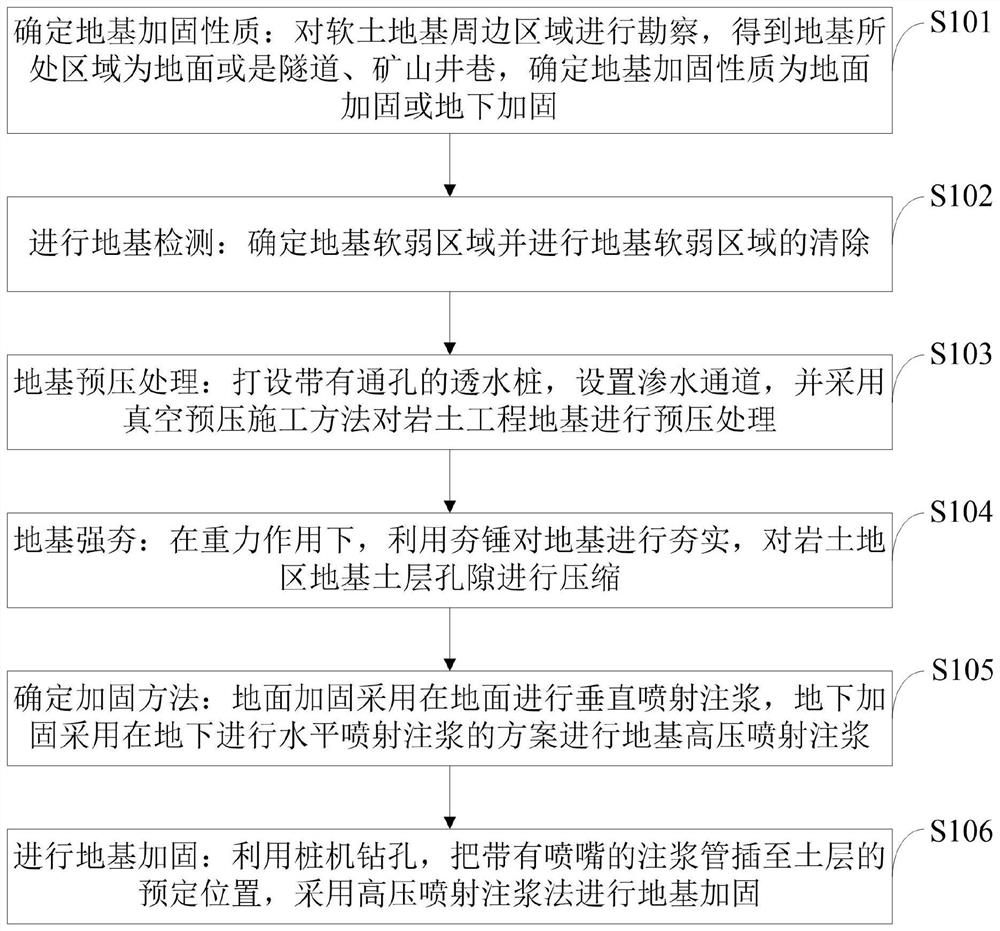

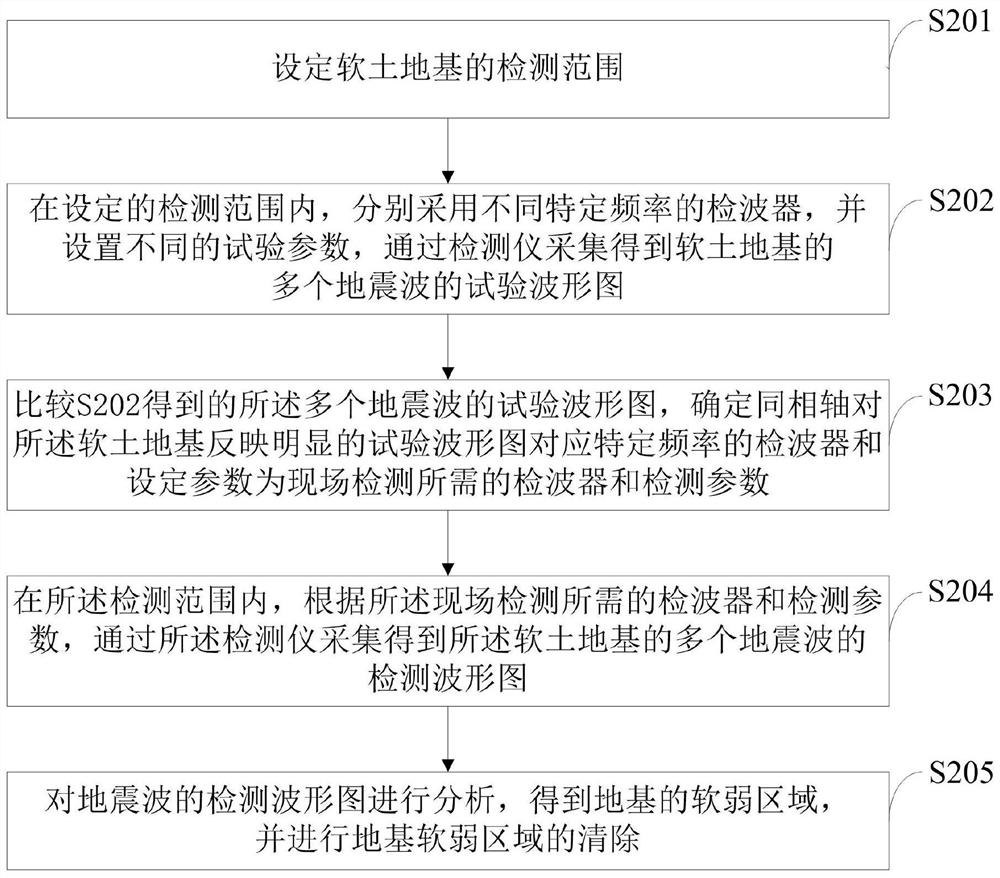

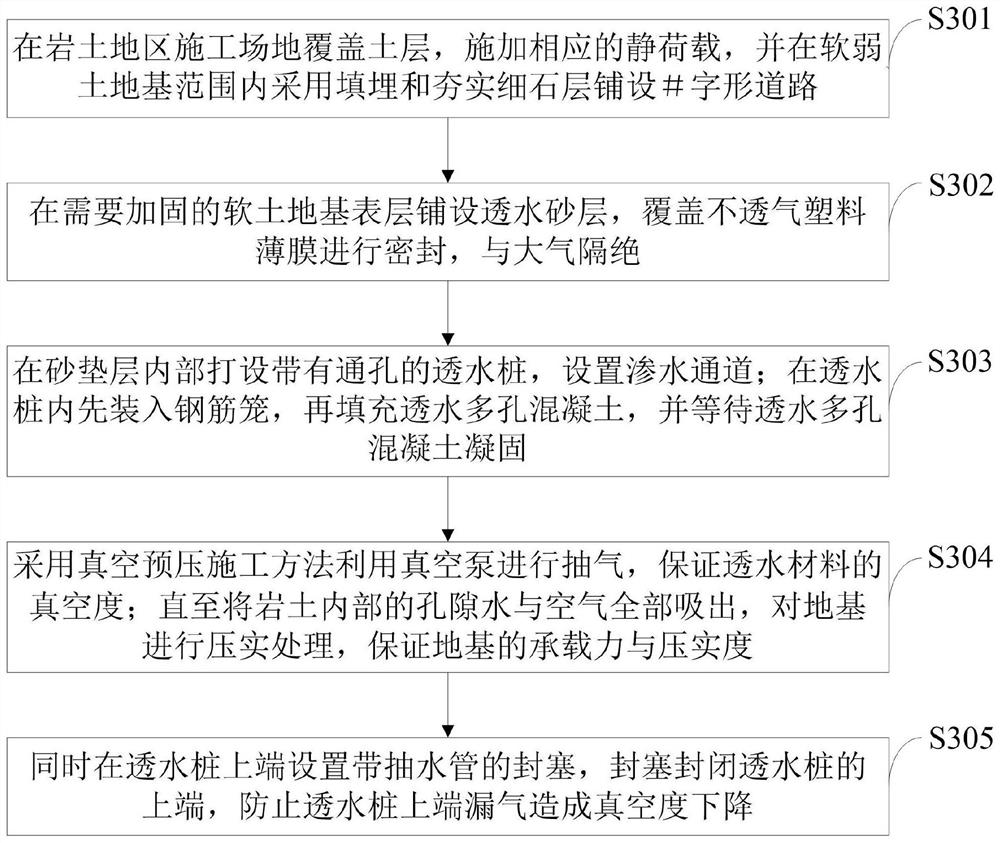

Method used

Image

Examples

Embodiment 1

[0077] Determine the nature of foundation reinforcement: conduct surveys on the surrounding areas of the foundation, find that the area where the foundation is located is the ground area, and determine the nature of the foundation reinforcement as ground reinforcement; conduct foundation detection: determine the weak area of the foundation and clear the weak area of the foundation; foundation preloading treatment: Vacuum preloading construction method is used to preload the foundation of geotechnical engineering; dynamic compaction of the foundation: under the action of gravity, the foundation is rammed with a rammer to compress the pores of the foundation soil layer in the rock and soil area; the reinforcement method is determined: ground reinforcement Use vertical jet grouting on the ground; carry out foundation reinforcement: use a pile driver to drill holes, insert a grouting pipe with a nozzle to a predetermined position in the soil layer, and use high-pressure jet grou...

Embodiment 2

[0079] Carry out grouting grout performance test:

[0081]

[0082] 2. Cement + clay:

[0083]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com