Construction method for foundation connecting joint of steel pipe column of fabricated bailey truss

A construction method and a technology for connecting nodes, which are applied in the direction of basic structure engineering, architecture, building construction, etc., can solve the problems such as the difficulty in ensuring the verticality of the joint length of steel pipes and steel pipes, the impact of structural systems on the safety of forces, and the difficulty in ensuring quality, etc. To achieve the effect of safety and easy guarantee, fast construction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

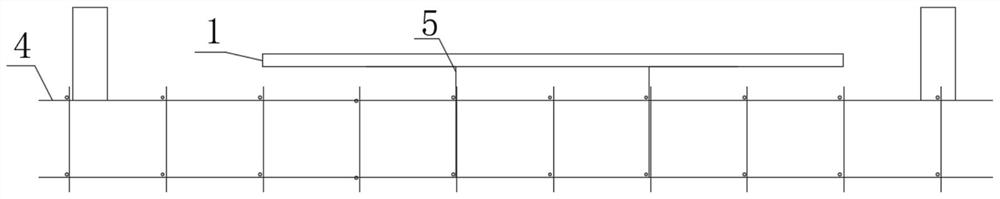

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. To explain the present invention, but not as a limitation of the present invention.

[0036] It should be noted that all directional indications (such as up, down, left, right, front, back, upper end, lower end, top, bottom, etc.) If the specific posture changes, the directional indication will also change accordingly.

[0037] In the present invention, unless otherwise specified and limited, the term "connection" should be understood in a broad sense. For example, "connection" can be a fixed connection, a detachable connection, or an integral body; it can be a mechanical connection, or It may be an electrical connection; it may be a direct connection, it may also be an indirect connection through an intermediary,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com