Air inlet self-cleaning system for engineering machinery

A construction machinery and self-cleaning technology, applied in the charging system, mechanical equipment, fuel air filter and other directions, can solve the problems of complex self-cleaning air filter structure and long self-blowing time interval, shorten the self-cleaning time, Reduce labor intensity and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

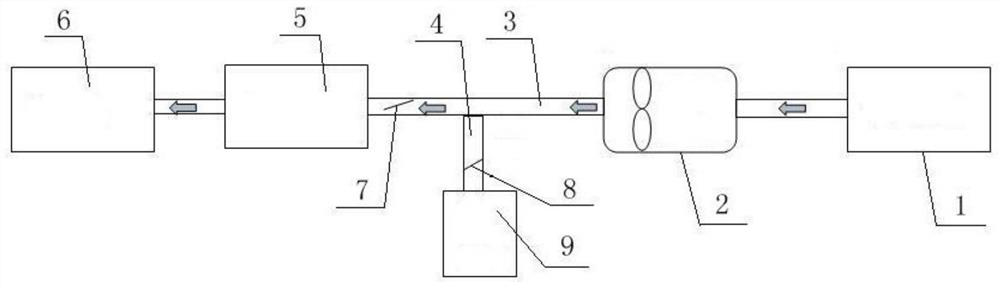

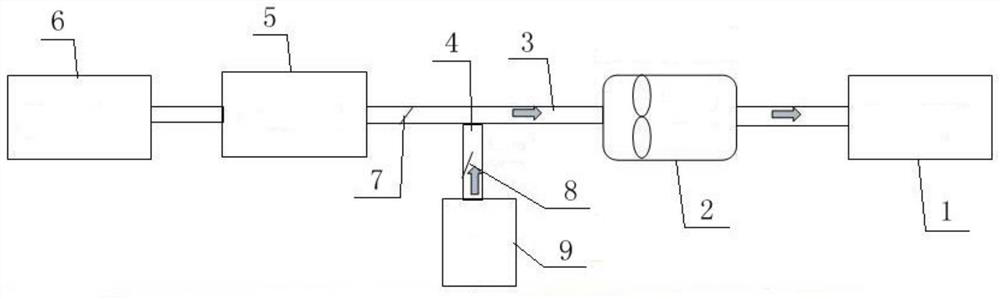

[0020]Example 1: Such asfigure 1 ,figure 2 As shown, the air intake self-cleaning system for construction machinery in this embodiment includes a first-stage dry air filter 1, a main ventilation pipe 3, and a second-stage dry air filter 5. The first-stage dry air filter 1 It is connected with the second-stage dry air filter 5 through the main ventilation pipeline 3. The main ventilation pipeline 3 between the first-stage dry air filter 1 and the second-stage dry air filter 5 is equipped with a duct fan 2. An air inlet pipe 4 is installed at the air inlet of the secondary dry air filter 5, a check valve A7 is provided on the main ventilation pipe 3, and a check valve B8 is provided on the air inlet pipe 4.

[0021]Further, a third-stage dry air filter 9 is connected to the air inlet pipe 4, and the third-stage dry air filter 9 is used to provide a clean air source for the back-blowing process.

[0022]Further, when the rated air volume of the selected duct fan 2 is greater than the intake ...

Embodiment 2

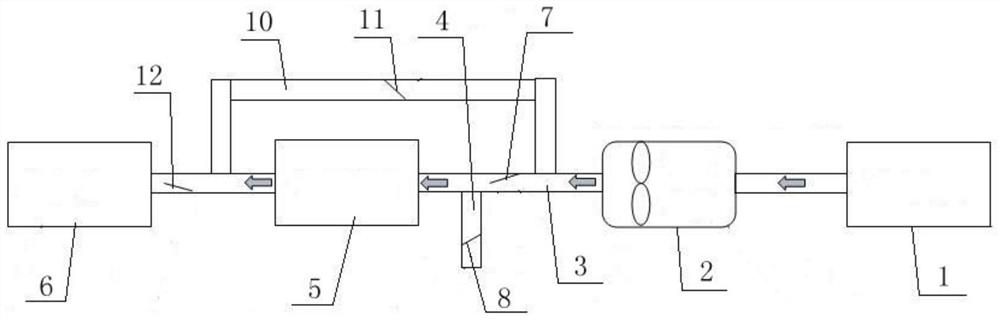

[0026]Example 2: Such asimage 3 ,Figure 4As shown, the air intake self-cleaning system for construction machinery shown in this embodiment includes a first-stage dry air filter 1, a second-stage dry air filter 5, and a main ventilation pipe 3. The first-stage dry air filter 1 It is connected with the second-stage dry air filter 5 through the main ventilation pipe 3 ways. The main ventilation pipe 3 between the first-stage dry air filter 1 and the second-stage dry air filter 5 is equipped with a duct fan 2. An air inlet pipe 4 is installed at the air inlet of the secondary dry air filter 5, a check valve A7 is installed on the main ventilation pipe 3, and a check valve B8 is installed on the air inlet pipe 4; the second stage dry air filter 5 A bypass pipeline 10 is connected between the front and rear ends, a check valve C11 is provided on the bypass pipeline 10, and the main ventilation pipeline 3 between the second-stage dry air filter 5 and the engine 6 is provided Check valve D1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com