Method for calculating bearing capacity of ultra-high-voltage transmission tower true test data node main pipe

A transmission tower, test data technology, applied in the direction of electrical digital data processing, special data processing applications, towers, etc., can solve the problem of no theoretical and experimental basis, and achieve the effect of small deviation

Inactive Publication Date: 2020-12-22

CHONGQING YUHUANG ELECTRIC POWER EQUIP MFG

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The form of the pipe joints in the special structure of the transmission tower is relatively special. In actual engineering, in order to improve the safety reserve of the design, some structural measures are often added to the joints. Regarding how to consider the beneficial effects of these structural measures, there is currently no There is no certain theoretical and experimental basis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0066] A calculation method for the main bearing capacity of a K-type joint connected by a steel pipe-plate connection, comprising the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for calculating the bearing capacity of a main pipe of a data node of an ultra-high voltage transmission tower true-type test, and the method comprises the following steps: carrying out the K-type node bearing capacity test of a test component of a steel pipe plugboard, and determining main factors affecting the bearing capacity of a K-type node; establishing an influence model of each factor on the bearing capacity of the K-shaped node; fitting finite element results in each influence model, and establishing a suggestion model for calculating the bearing capacity of the K-type node; substituting each factor parameter of the K-shaped node connected with the steel pipe plugboard to be evaluated into the suggestion model to obtain the ultimate main pipe bearing capacity value of the K-shaped node connected with the steel pipe plugboard. According to the method, the bearing capacity calculation model of the K-shaped node connected with the annular reinforcing plate steel pipe inserting plate is obtained through the energy principle, the mutual relation among the main pipe axial force, the main pipe wall bending moment and the shearing force is reflected, the ultimate bearing capacity of the K-shaped node can be accurately evaluated, and the deviation between the ultimate bearing capacity and the test result is small.

Description

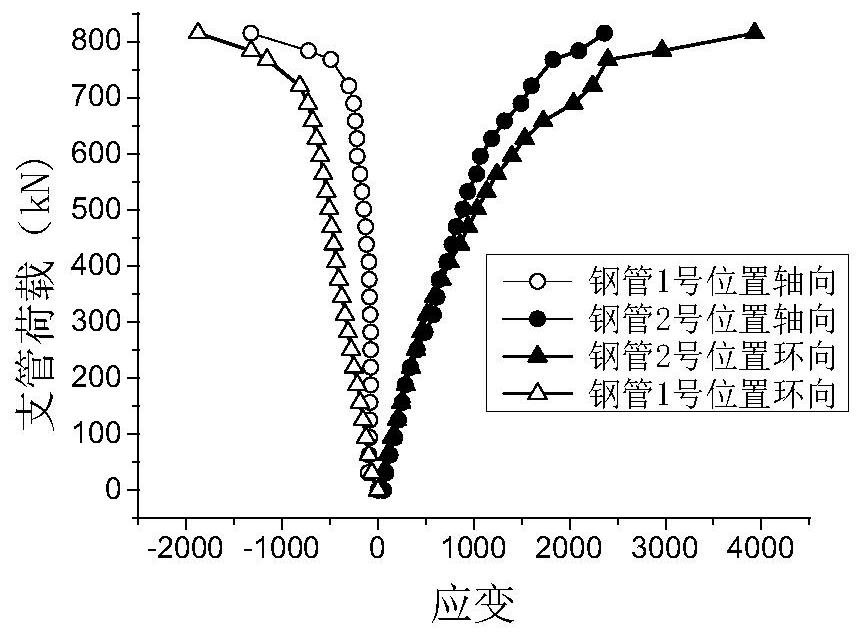

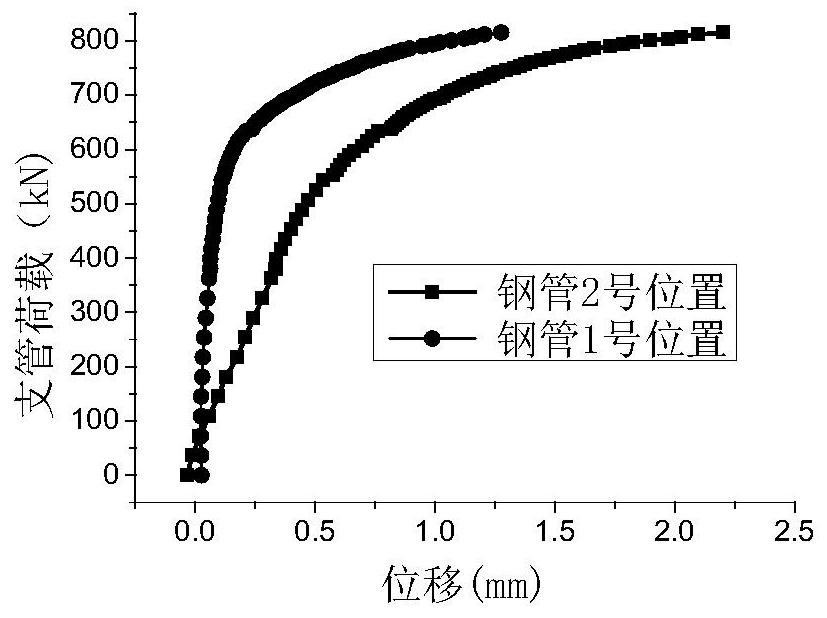

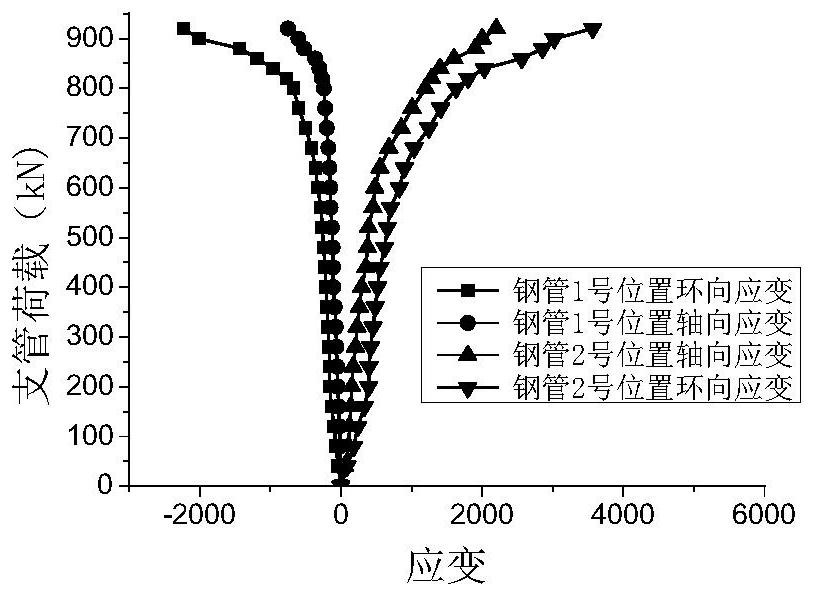

technical field [0001] The invention relates to the field of transmission iron towers, in particular to a method for calculating the bearing capacity of a superintendent of data nodes in a real-type test of an ultra-high voltage transmission iron tower. Background technique [0002] The steel pipe tower with pipe-connection joints has the problem of local buckling of steel pipes. In actual transmission towers, ring stiffeners are added to reduce the influence of local buckling. However, there is no corresponding design checking method in my country. In December 2008, the phenomenon of local buckling of steel pipes was observed in the true type test of the SZT2 tower of the "1000kV AC same-tower double-circuit transmission line tower research" project jointly undertaken by China Electric Power Research Institute and China Consulting Group Corporation. China The Electric Power Research Institute has also initially carried out experimental research on local buckling of steel pi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F30/23E04H12/08G06F119/14

CPCG06F30/23E04H12/08G06F2119/14

Inventor 欧阳宇恒

Owner CHONGQING YUHUANG ELECTRIC POWER EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com