A force component anti-compression type cable trench

A cable trench and force distribution technology, applied in cable installation, ground cable installation, electromechanical devices, etc., can solve the problems of difficult to support the frame, poor compression resistance, improve weighing capacity, etc., and achieve the effect of improving compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

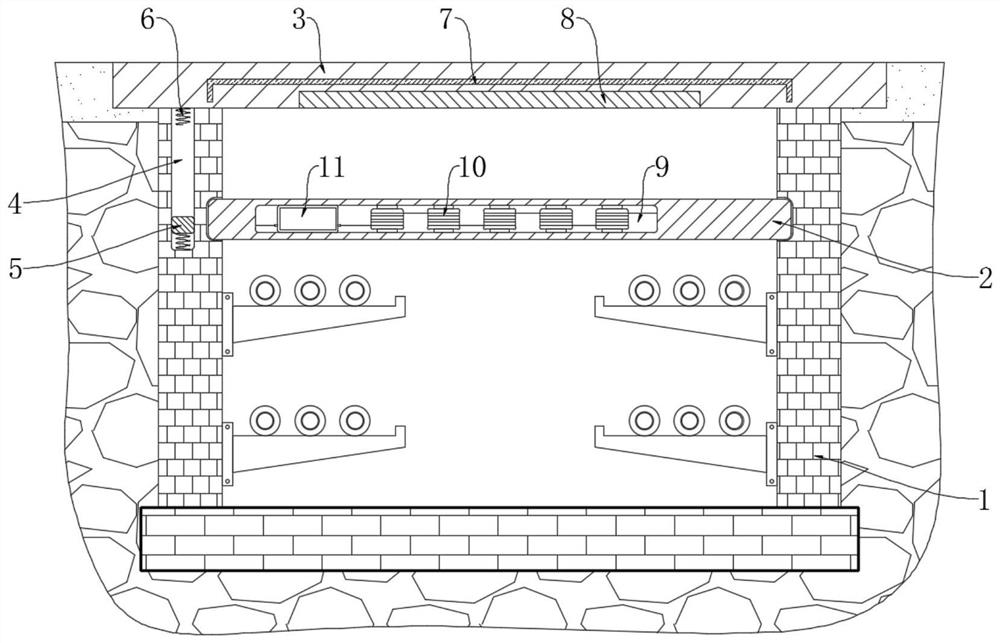

[0023] Refer figure 1 A compression-type cable duct component, comprising a cable trench symmetrically two side panels 1, the two side panels 1 on a common support plate 3 ditch, trench cover 3 is flush with the road surface, the trench lower surface of the cover plate 3 provided with a magnetic insert 8, wherein said one side plate defines a guide rail 4, the guide rail 4 is provided around the outer lead wire, said top and bottom slide 4 are reciprocally welded spring 6 is fixed, the two shuttle spring upright 5 has a magnetic stripe, stripe 5 slidably up and down between the guide rail 4 6, the shuttle spring 6 extended vertically slidable time stripe 5 At the same time, a collision can be avoided strong magnetic strip 5 and guide rails 4 or bottom wall occurs, resulting in loss of the magnetic stripe 5, between the two side plates fixed to a shield plate 2 is attached, is an insulating shield plate 2 made of a rigid material, said protective panel of said circuit module 2 defi...

Embodiment 2

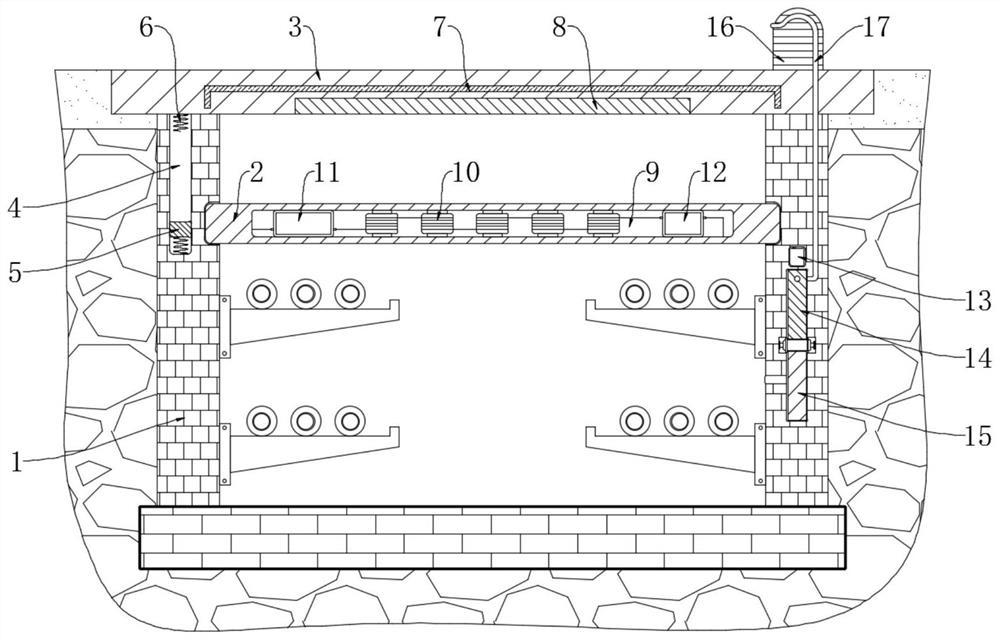

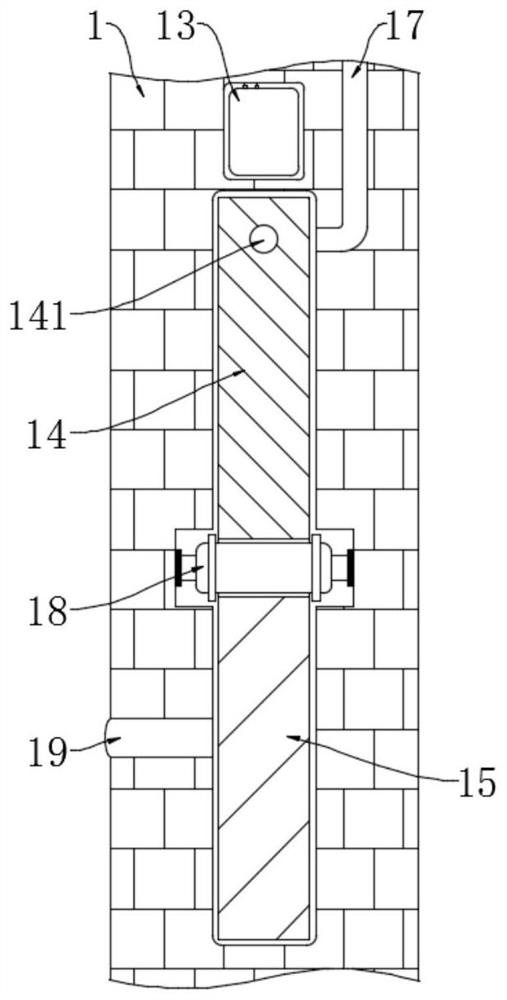

[0028] Refer Figure 2-4 The present embodiment is different from Embodiment 1 in that: a further side plate 1 is provided with warning means, the warning means comprises a side opening within a circular groove 21 through a rotating shaft 18 rotatably mounted within the circular groove 21 has a ferromagnetic plate 15, the ferromagnetic plate 15 is fan-shaped and the inner side wall of the circular groove 21 of the sealing slide contact, the circular groove 21 is fixed with a first fixing plate 14 and the second fixing plate 20, and the first and the second fixing plate 14 is fixed the upper plate 20 are respectively attached to first check valve 141 and the dust valve 201, the communication between the interior of the circular groove 21 and the cable channel has an intake pipe 19 and intake pipe 191 is attached to the third check valve 19.

[0029] In this embodiment, the warning means further comprises a groove and the cover plate 3 is fixedly connected to the warning device 16, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com