Heater and electrical equipment

A heater and heating wire technology, applied in the field of machinery, can solve problems such as poor user experience, unbalanced temperature of the heater’s air outlet, and large wind resistance, so as to improve heating efficiency and conversion efficiency, and solve the problem of unbalanced air outlet temperature , the effect of reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

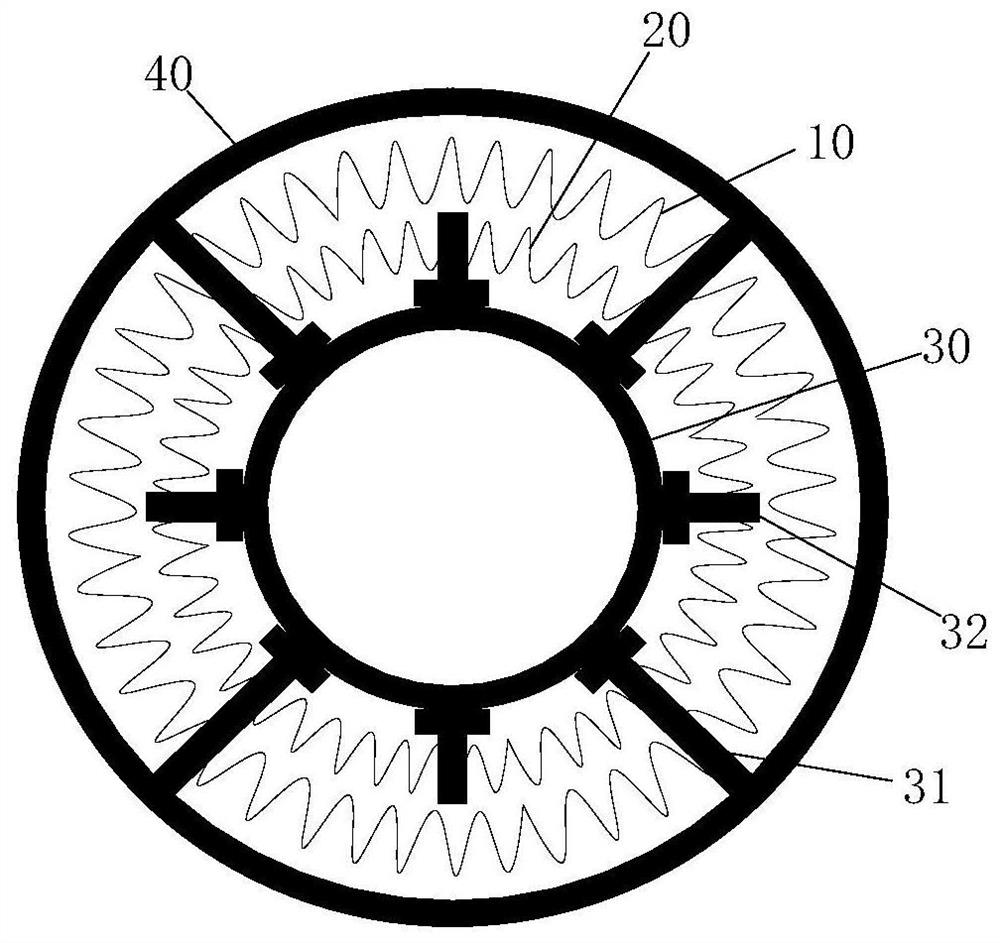

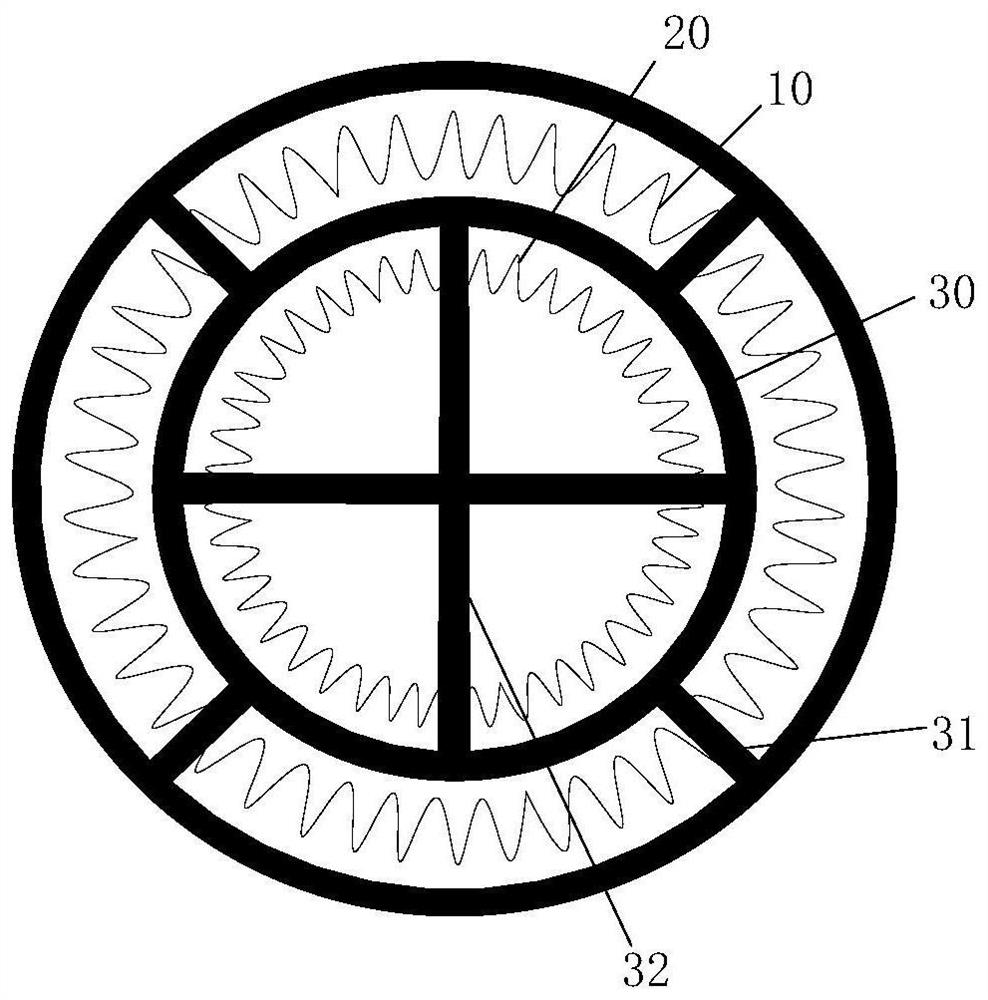

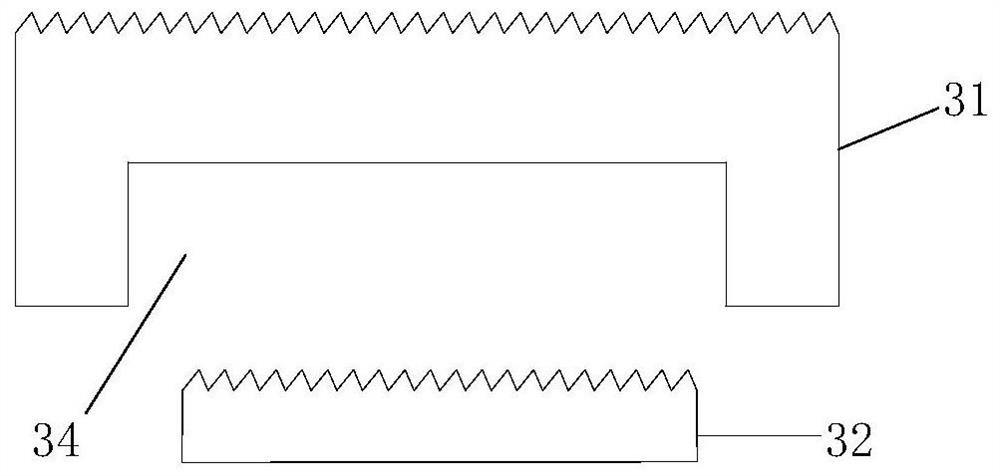

[0023] In the existing technology, the structures of the heating wires in the heaters are different, but most of the heaters still have certain defects. The temperature imbalance problem. In addition, multi-layer heating wires are arranged in the heater, and each layer of heating wires needs a support member. Multiple support members lead to the increase of wind resistance of the air duct and the problems of temperature imbalance.

[0024] In view of the above problems, the embodiment of the present invention provides a heater and electrical equipment. Both the first heat generating layer and the second heat generating layer of the heater are supported by the same support body, which does not need to be supported separately, thus reducing the number of support bodies. The number effectively reduces the heating space of the heater and reduces the wind resistance, thereby solving the problem of unbalanced air temperature and improving the heating efficiency and conversion effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com