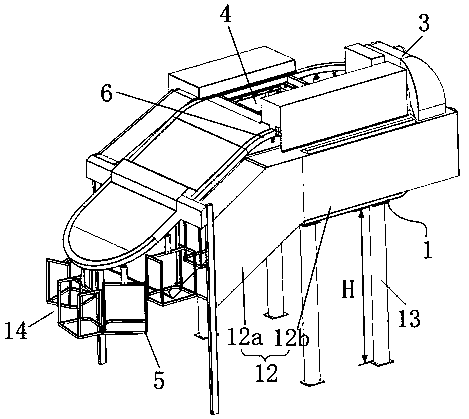

A vacuum vulcanizer for shoemaking

A vulcanizing machine and vacuum technology, which is applied to insoles, shoe uppers, footwear, etc., can solve the problems of vulcanizing machines occupying a large space, not meeting energy-saving requirements, and high site costs, etc., achieving reduced space, short time, and good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

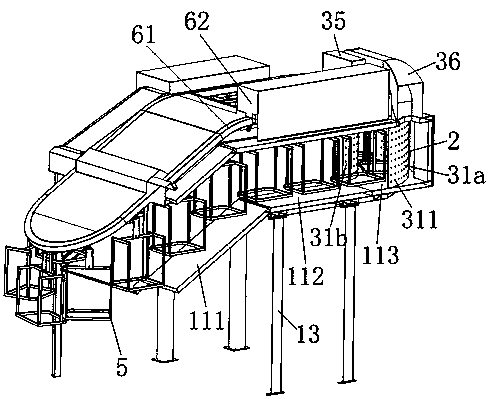

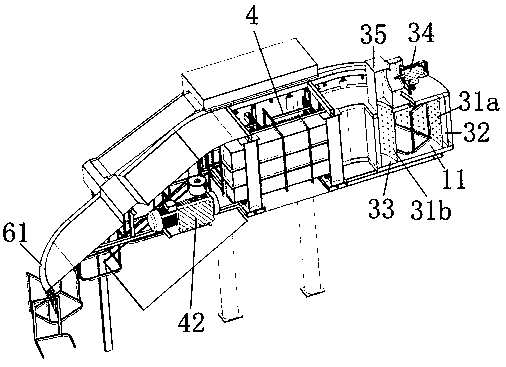

[0050] In the first embodiment, the drying tunnel 11 includes an inclined drying tunnel 111, a horizontal drying tunnel 112 and an arc-shaped drying tunnel 113 arranged in sequence along the moving direction of the conveying chain ring 61, and the inclined drying tunnel 111 is arranged at the left oblique straight part Or at the right oblique straight part, the arc-shaped drying tunnel 113 is arranged at the horizontal arc-shaped transition part 611;

[0051] In the second embodiment, the drying tunnel 11 includes a horizontal drying tunnel 112 and an arc-shaped drying tunnel 113 arranged in sequence along the moving direction of the conveying chain ring 61 , and the arc-shaped drying tunnel 113 is arranged at the horizontal arc-shaped transition portion 611 .

[0052] That is to say, it is preferable to set both the straight section and the horizontal arc-shaped transition portion 611 as the drying tunnel 11. At this time, the drying tunnel 11 has a large space and can fully h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com