Production line for foam floor mats

A production line and floor mat technology, which is applied in the field of floor mat processing, can solve the problems of slow heating speed, slow down of the production process of floor mats, and low degree of automation, and achieve the effects of fast heating speed, improved product quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

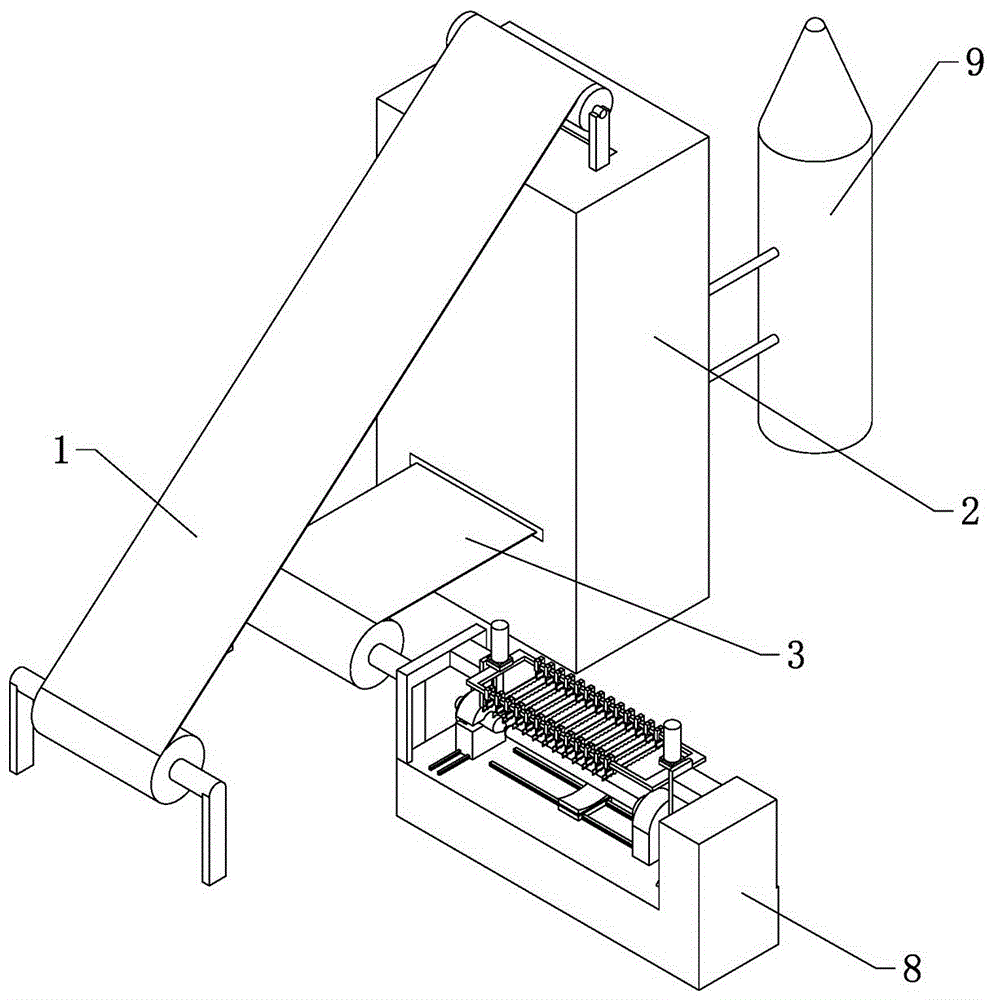

[0034] according to Figure 1 to Figure 5As shown, a foaming floor mat production line includes: a feeding device 1, a processing chamber 2, a receiving device 3, a cutting device 8 and a cooling device 9;

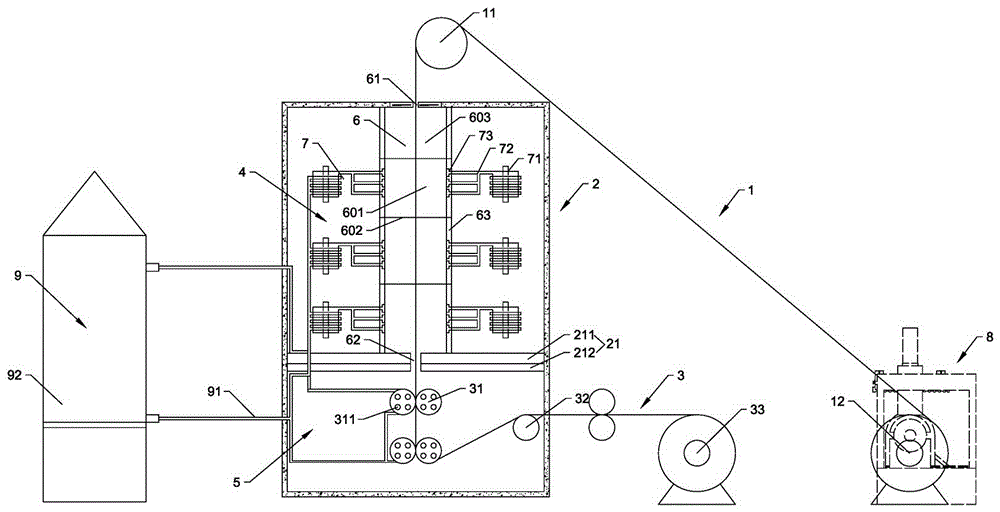

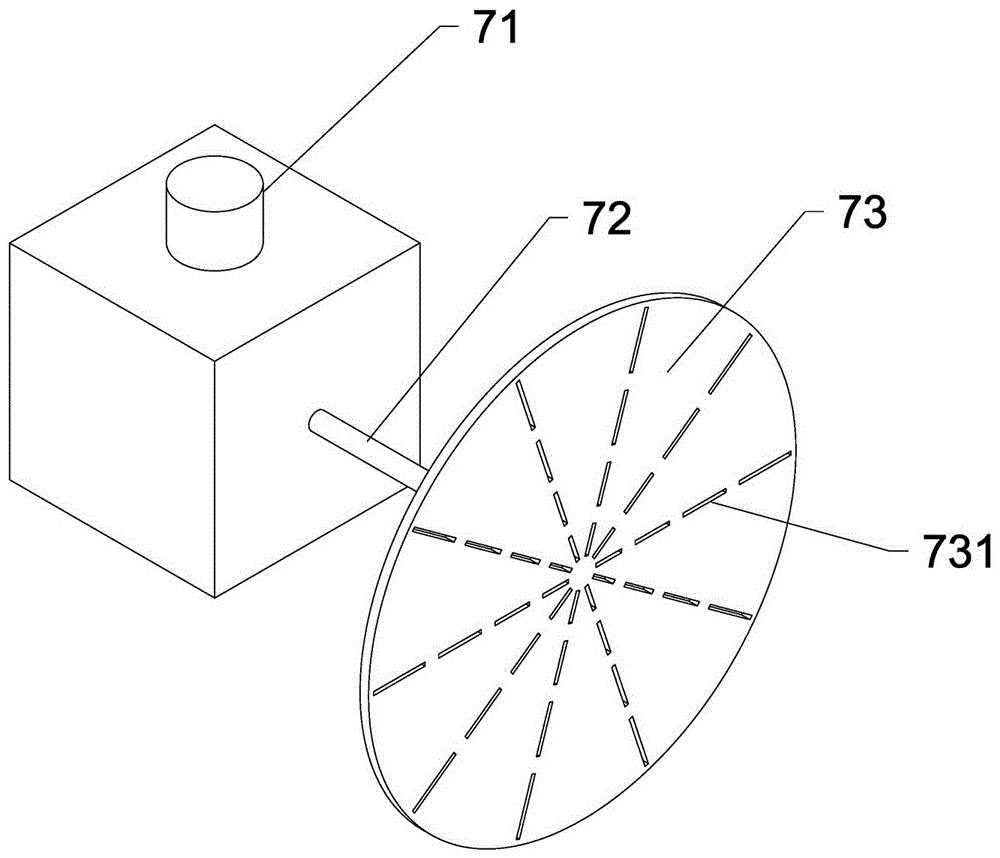

[0035] The processing chamber 2 includes: a heating zone 4 for material foaming and a cooling zone 5 for material shaping, the heating zone 4 and the cooling zone 5 communicate with each other, and the opening between the heating zone 4 and the cooling zone 5 is provided. Belt 21; the heating zone 4 comprises, the foaming channel 6 of elongated cross-section and the heating system 7 used for heating the material in the foaming channel 6, and the two ends of the foaming channel 6 along the material conveying direction are respectively provided with slit-shaped The material inlet 61 and the material outlet 62, the inner wall of the foaming channel 6 is provided with a reflective layer 63; the heating system 7 includes a wave source transmitter 71, a waveguide 72 and an energ...

Embodiment 2

[0049] The difference from the first embodiment above is that the foaming channel 6 includes a resonant region 601 . The resonance area 601 has a rectangular three-dimensional structure, and the energy feeding ports 73 are symmetrically distributed on two horizontally opposite side walls of the resonance area 601 , and each side wall is provided with a plurality of energy feeding ports 73 . The side lengths of the resonance region 601 and the vibration frequency f of the waves emitted by the wave source transmitter 71 are 915MHz, the power is 100kw, and the length, width and height of the resonance region 601 are 150cm, 50cm and 100cm respectively. A temperature controller is provided in the resonance area 601, the temperature controller includes a temperature detector and a power regulator, and controls the temperature in the resonance area 601 to be 160°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com