Soil remediation device

A technology of soil remediation and remediation solution, applied in the field of soil remediation devices, can solve the problems of incomplete soil remediation and no function of removing impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

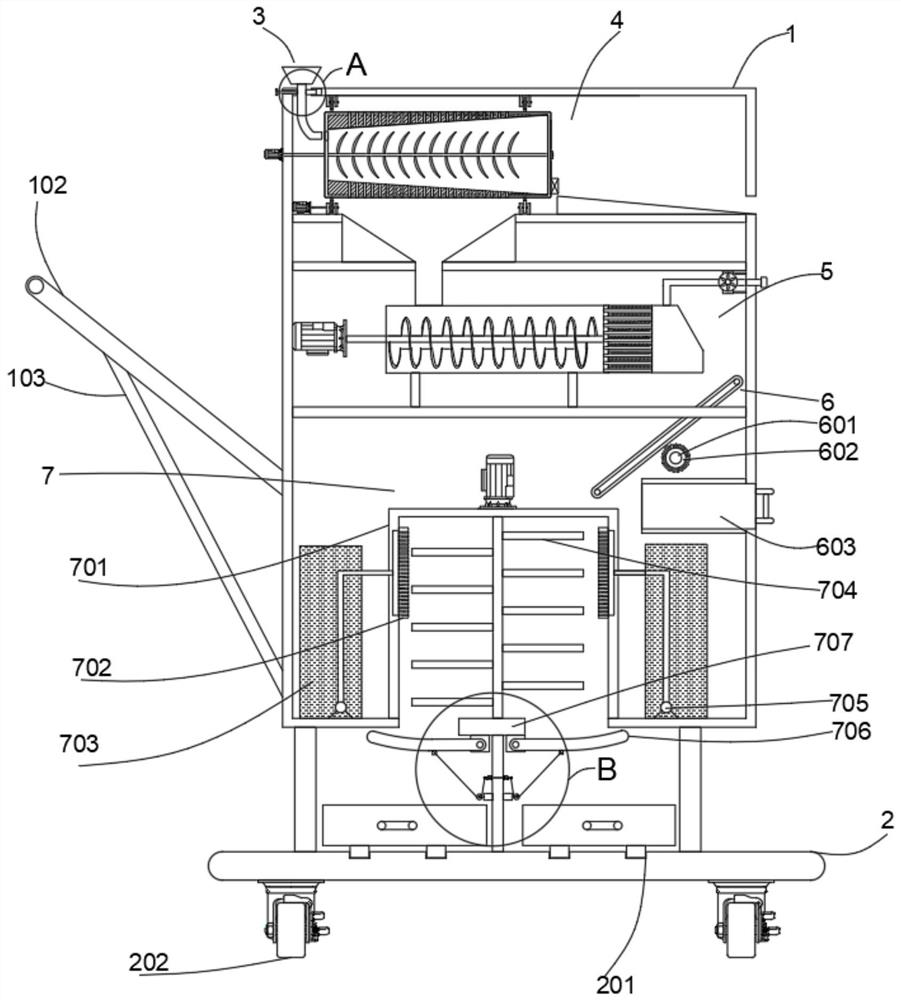

Embodiment 1

[0030] refer to Figure 1-6, a soil remediation device, comprising a box body 1 and a bottom plate 2, the box body 1 is a hollow structure, the box body 1 is fixedly connected with the bottom plate 2 through a first connecting rod, and the inner cavity of the box body 1 is A crushing mechanism 4, a thermal decomposition mechanism 5, a metal adsorption mechanism, and a repair fluid spraying mechanism 7 are arranged in sequence from top to bottom. The upper left side of the box body 1 is provided with a feeding mechanism, and the raw materials enter the box body 1 from the feeding mechanism. , firstly through the treatment of the crushing mechanism 4, the gravel slag in it is separated and the soil is crushed, and then through the treatment of the thermal decomposition mechanism 5, the organic matter adsorbed in the soil is volatilized, and then the metal in the soil is decomposed by the metal adsorption mechanism. Remove, and then spray the repair liquid in the soil through the...

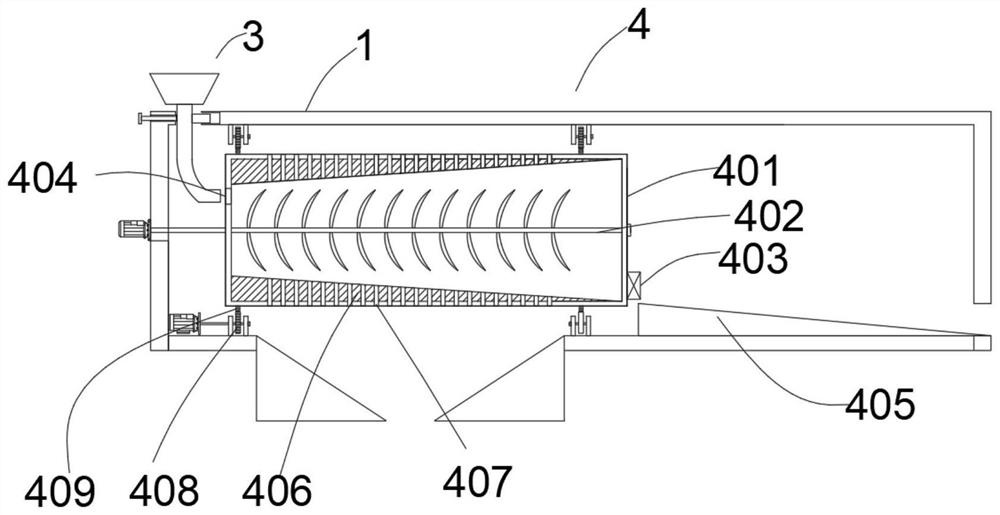

Embodiment 2

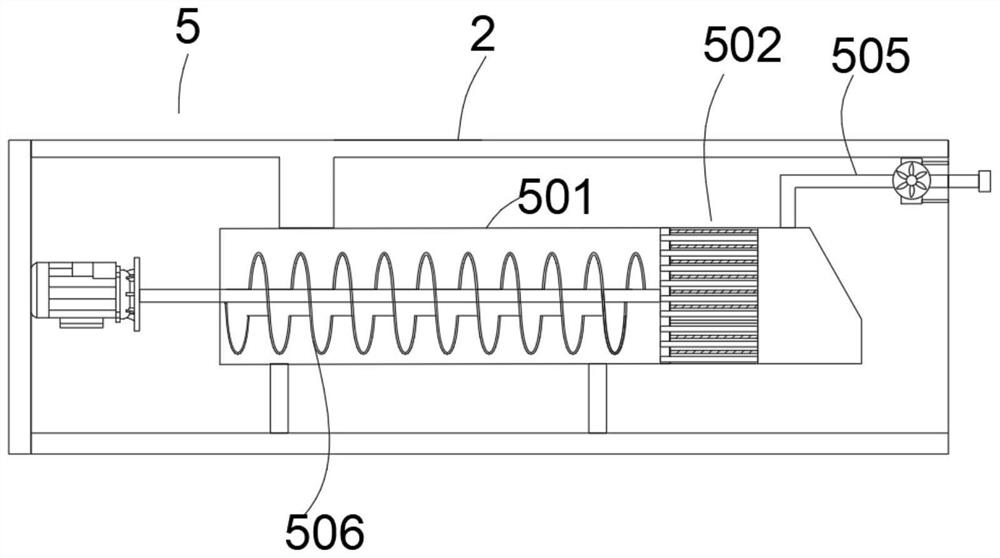

[0035] refer to figure 2 , a soil remediation device. This embodiment explains in detail the thermal decomposition mechanism 5 mentioned in Example 1. The thermal decomposition mechanism 5 includes a decomposition box 501, a decomposition ring 502 and a feeding dragon 506. The decomposition The upper side of the box 501 is provided with a second material inlet, and the feeding dragon 506 is arranged in the decomposition box 501 and is rotatably connected with it. A decomposition ring 502 is arranged in the decomposition box 501 on the right side of Jiaolong 506, and a plurality of soil circulation holes 503 are provided in the middle of the decomposition circle 502, and a heating rod 504 is arranged in the decomposition circle 502 around the soil circulation hole 503, The decomposition box 501 located on the right side of the decomposition circle 502 is connected to the outside air through an air outlet pipe 505, and an exhaust fan is arranged on the air outlet pipe 505; work...

Embodiment 3

[0037] refer to Figure 3-4 , a soil remediation device. This embodiment explains in detail the metal adsorption mechanism mentioned in Embodiment 1. The metal adsorption mechanism includes a transmission belt 6, a drive shaft 601 and a brush cover 602. The transmission belt 6 is arranged on On the lower right side of the thermal decomposition mechanism 5, the transmission belt 6 is provided with a magnetic attraction layer, and the transmission belt 6 is driven by a motor arranged on the outside of the casing 1, and the drive shaft 601 is arranged on the lower side of the transmission belt 6 and is connected with the casing The side walls of body 1 are rotationally connected, and the brush cover 602 is set in the outer ring of drive shaft 601; working principle: when the raw material falls on the transmission belt 6, the starting motor drives the transmission belt 6 to rotate counterclockwise, and at this time the drive shaft is rotated 601 drives the brush cover 602 to rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com