Vegetation concrete prefabricated slab

A technology for planting raw concrete and prefabricated panels, applied in the field of concrete, can solve the problems of inconvenient green planting, poor environmental protection, and grass seeds are easily washed away by rainwater, and achieve the effect of reducing moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

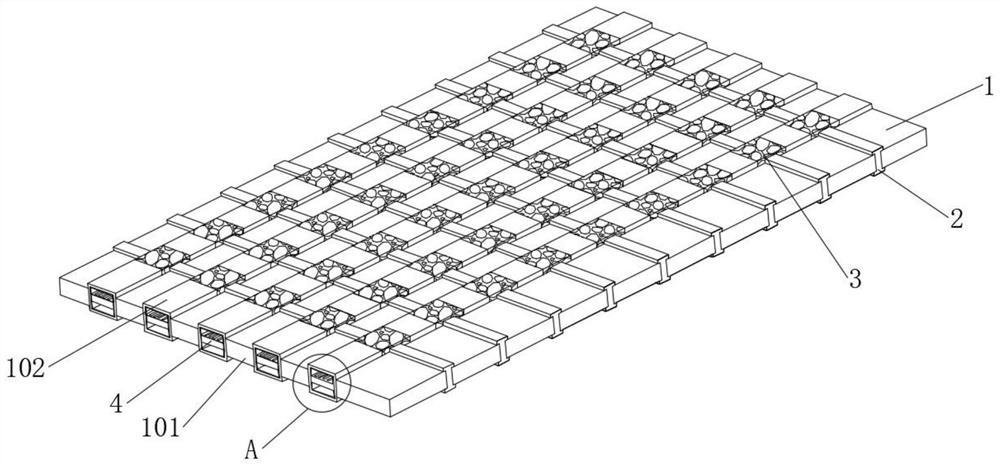

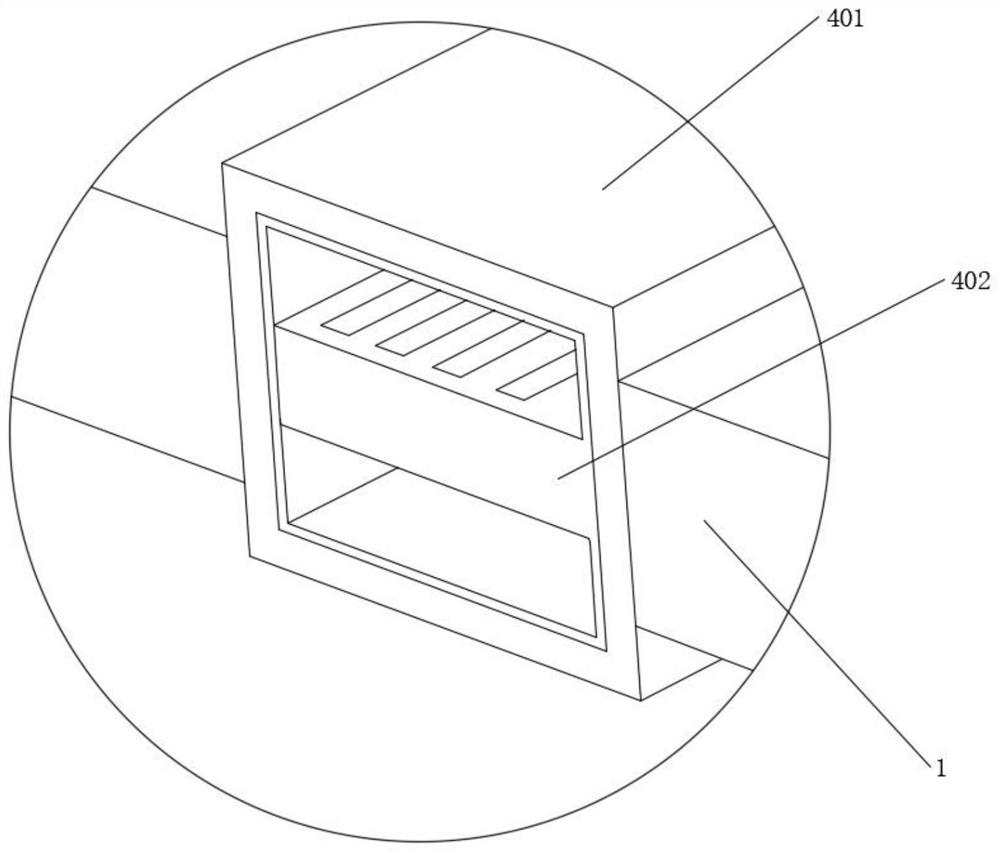

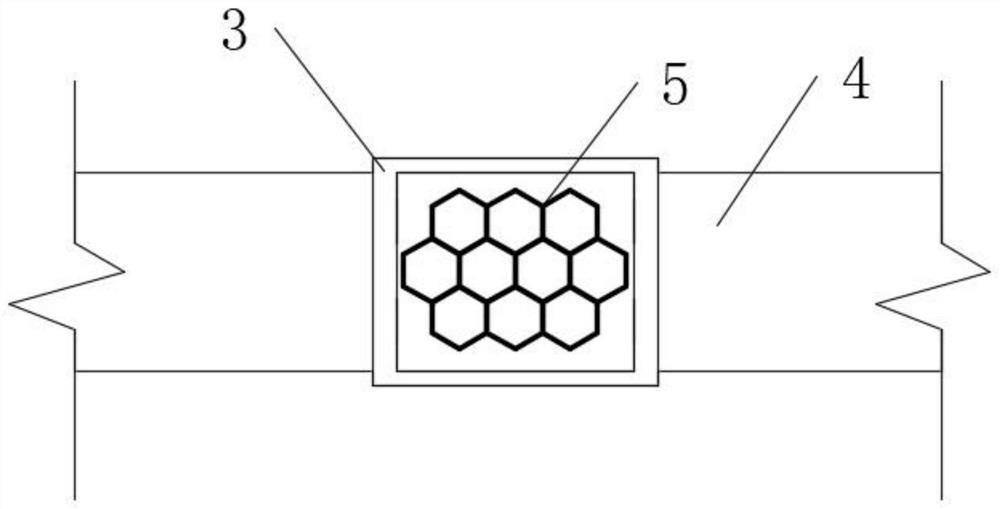

[0038] see Figure 1-3, a planting concrete prefabricated slab, comprising a concrete prefabricated slab 1, the concrete prefabricated slab 1 is made of self-repairing concrete pouring, the concrete prefabricated slab 1 is mixed with calcifying bacteria colonies, and the concrete prefabricated slab 1 is fixedly connected with a plurality of steel frames 2 A plurality of planting blocks 3 are fixedly connected to the steel frame 2, and a resin filling layer is connected between the prefabricated concrete plate 1 and the planting blocks 3. A shaping tube 4 is connected between the planting blocks 3 on two adjacent steel frames 2, a plurality of fixing bolts are connected between the shaping tube 4 and the planting blocks 3, and a plurality of cultivation holes are dug on the planting blocks 3, and the planting blocks 3 Including the hollow shell 301, the planting concrete is stored in the hollow shell 301, the planting concrete is mainly made of porous greening concrete, activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com