Grinding and polishing machine for automatic processing of special-shaped furniture

A technology for automatic processing and special-shaped parts, which is applied in the direction of grinding/polishing equipment, machine tools for surface polishing, metal processing equipment, etc. It can solve the problems of unable to polish cylindrical special-shaped furniture, inconsistent surface smoothness, waste of resources, etc., and achieve continuous Polishing work, consistent smoothness, effect of improving polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

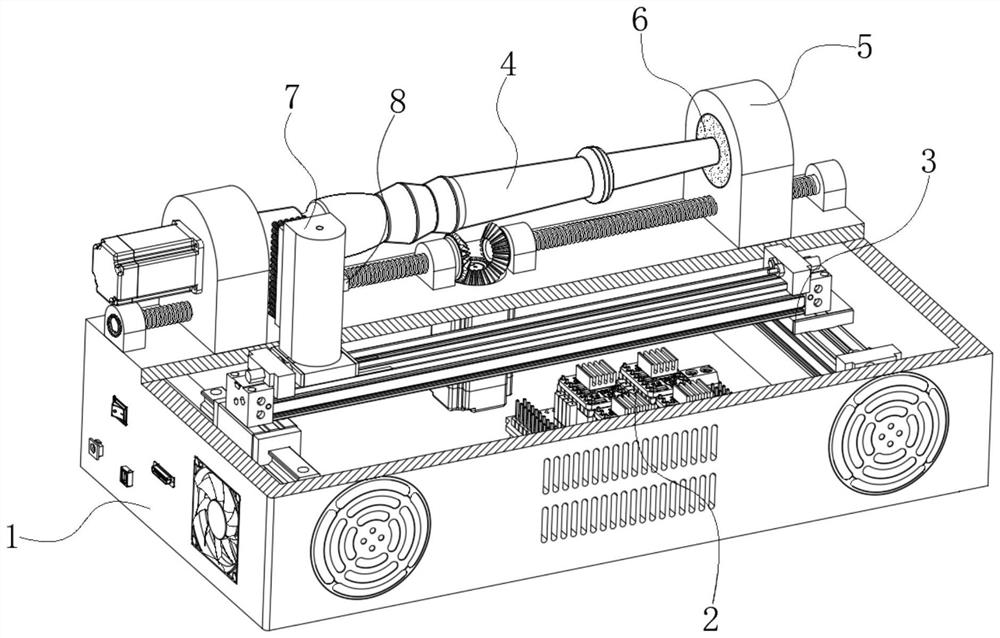

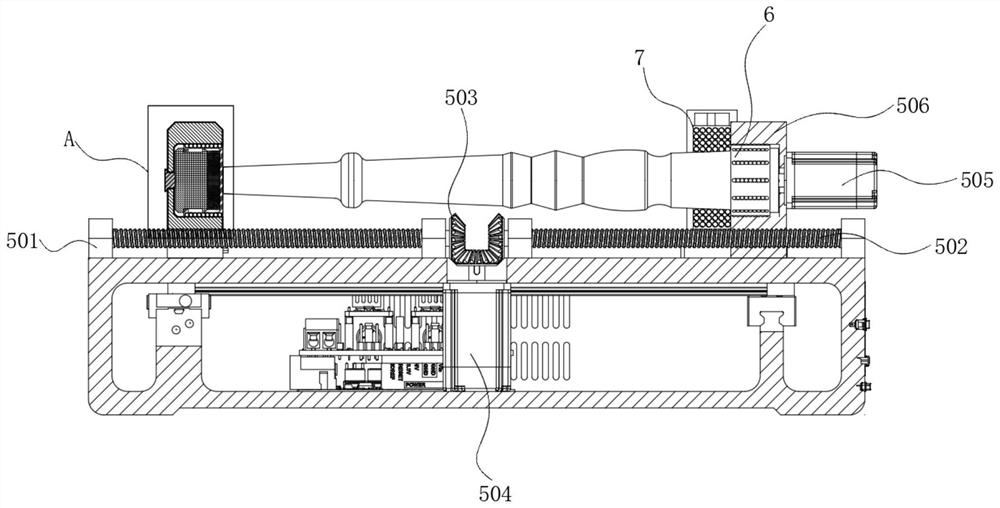

[0045] refer to figure 1, the present invention provides a technical solution: a grinding and polishing machine for automatic processing of special-shaped furniture, which includes a base 1, a transfer device 3, a clamping assembly 5, a pretensioning assembly 6, a polishing assembly 7 and an induction assembly 8, wherein the The transfer device 3 is arranged in the base 1, and the side wall of the base 1 is provided with multiple groups of cooling holes and cooling fans for removing the heat inside the base 1, and the base 1 is also provided with a controller 2;

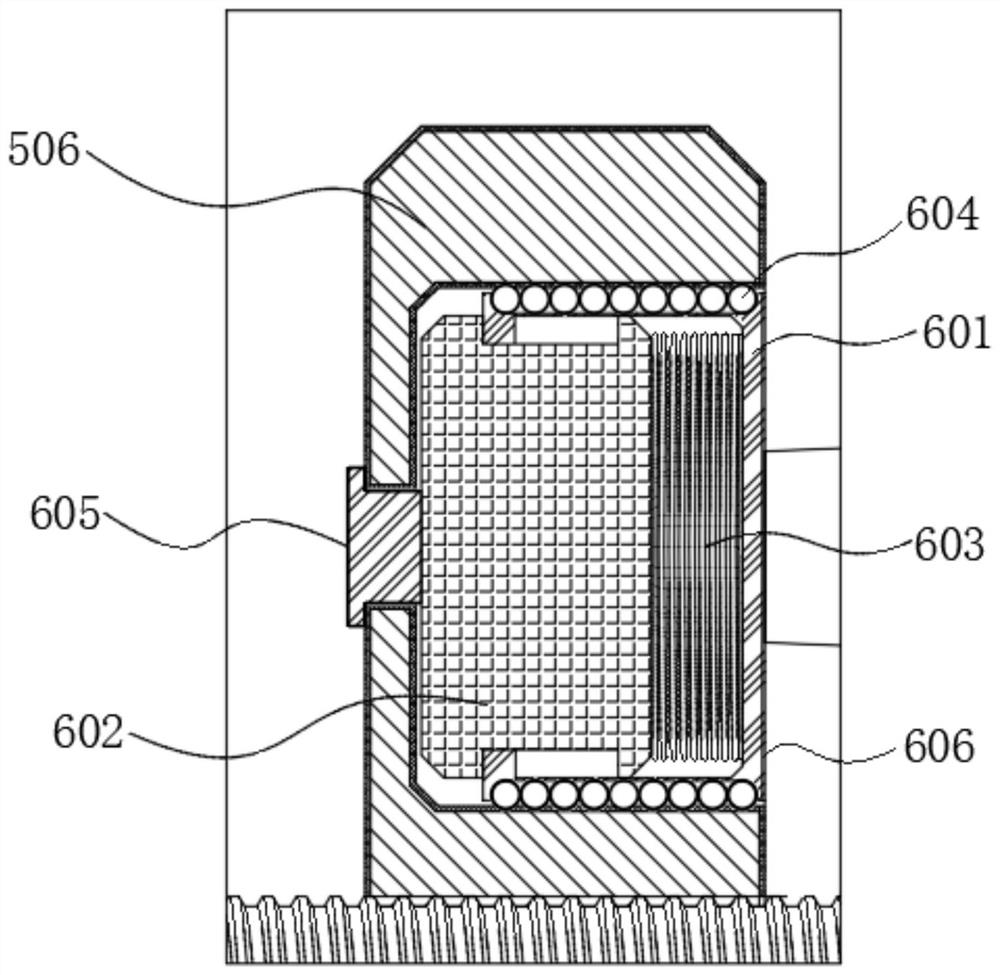

[0046] The clamping assembly 5 is arranged on the upper end surface of the base 1 through the bearing seat 501, and the pre-tightening assembly 6 is arranged in the clamping assembly 5, and the pre-tightening assembly 6 can perform preliminary clamping on the special-shaped furniture 4;

[0047] The polishing assembly 7 is fixed on the output end of the transfer device 3, and the transfer device 3 can drive the polis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com