A kind of chamfering machine for ceramic ferrule production line and using method thereof

A ceramic ferrule and production line technology, which is applied in the field of chamfering machines for ceramic ferrule production lines, can solve the problems of low processing efficiency and long working hours, and achieve the effect of reducing chamfering man-hours and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

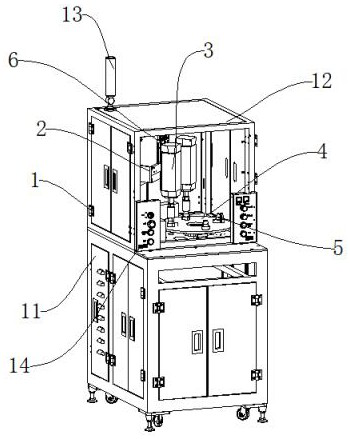

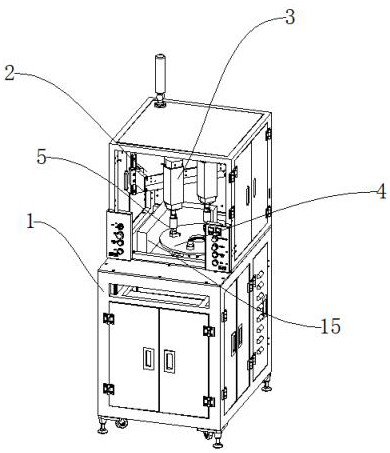

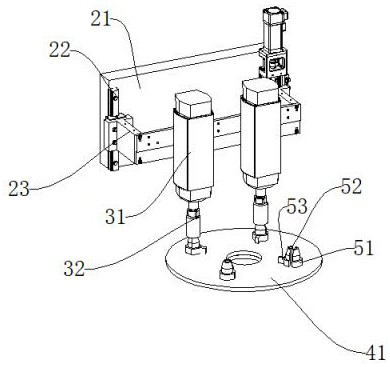

[0051] like Figure 1-Figure 7 As shown, a chamfering machine for a ceramic ferrule production line includes a clamping mechanism 5 for clamping the ceramic ferrule, a rotating mechanism 4 for rotating the ceramic ferrule, and a chamfering mechanism 3 for processing chamfering, A clamping mechanism 5 is installed on the rotating mechanism 4, a chamfering mechanism 3 is arranged on the upper side of the clamping mechanism 5, and the chamfering mechanism 3 is installed on the lifting mechanism 2. The power end of the lifting mechanism 2 is provided with a power mechanism 6, and the outside of the rotating mechanism 4 connect external institutions 1;

[0052] The external mechanism 1 includes a base 11, an outer box 12, a status light 13, and a control panel 14. An outer box 12 is installed on the upper end of the base 11, a status light 13 is installed on the upper end of the outer box 12, and a control panel is arranged at the front end of the outer box 12. 14. The vacuum clea...

Embodiment 2

[0060] like Figure 8 , the difference between this embodiment and Embodiment 1 is:

[0061] The power mechanism 6 includes a lifting cylinder 611 , a cylinder mounting seat 612 , and a connecting seat 613 . The lower end of the lifting cylinder 611 is connected to the cylinder mounting seat 612 , the cylinder mounting seat 612 is installed on the fixed seat 21 , and the power end of the lifting cylinder 611 is connected to the lifting seat through the connecting seat 613 23. When the chamfering motor 31 needs to be lifted and lowered, the lifting cylinder 611 is activated to drive the connecting seat 613, so that the lifting seat 23 can drive the chamfering motor 31 to lift and lower.

[0062] A method for using a chamfering machine for a ceramic ferrule production line, comprising the following steps:

[0063] a. Place the ceramic ferrule that needs to be chamfered between the fixed clamp block 51 and the movable clamp block 52 at the front end. At this time, the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com