A kind of variable diameter self-screening method of plastic particles

A technology for plastic particles and screening methods, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of poor flexibility, difficulty in screening, low work efficiency, etc., to prevent mutual adhesion, Avoid excessive bonding and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

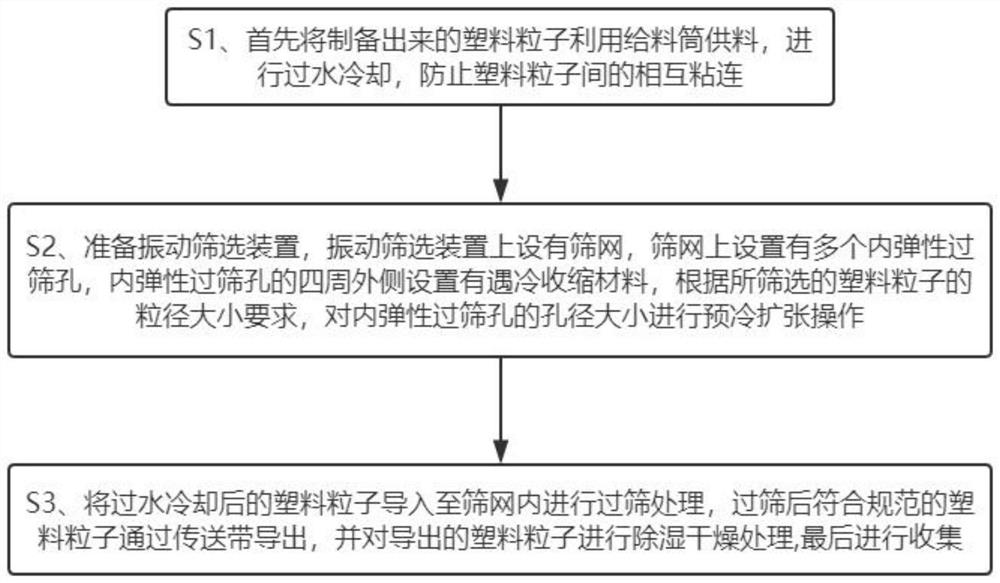

[0043] see Figure 1-4 , a plastic particle variable diameter self-screening method, the specific screening method is as follows:

[0044] S1. Firstly, the prepared plastic particles are fed by the feeding cylinder, and cooled by water to prevent the plastic particles from sticking to each other;

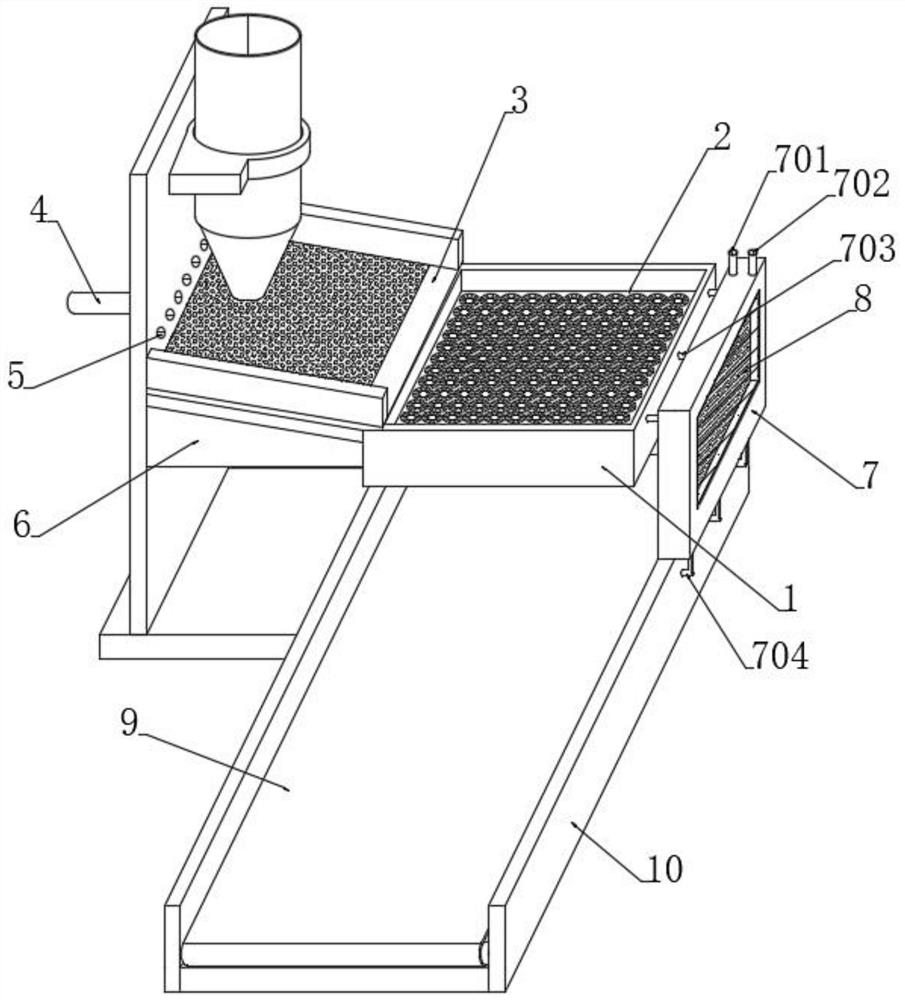

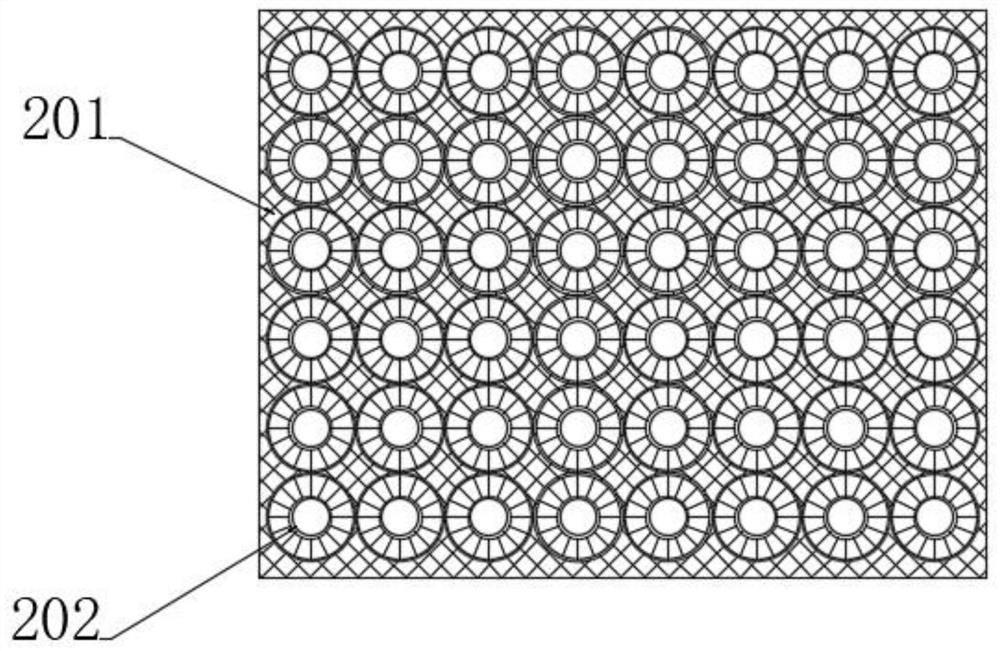

[0045] S2, prepare the vibrating screening device 1, the vibrating screening device 1 is provided with a screen 2, the screen 2 is provided with a plurality of inner elastic sieve holes 2023, and the outer sides of the inner elastic sieve holes 2023 are provided with cooling shrinkage materials, According to the particle size requirements of the screened plastic particles, pre-cooling and expanding the pore size of the inner elastic sieve hole 2023;

[0046] S3. Introduce the water-cooled plastic particles in S1 to the screen 2 for sieving treatment. After sieving, the plastic particles that meet the specifications are exported through the conveyor belt 9, and the exported plastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com