Automatic light paper box production conveying equipment

A technology of conveying equipment and cartons, which is applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems of unsmooth output, strength drop, easy deformation, etc., and achieve the effects of avoiding waste products, increasing service life, and ensuring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

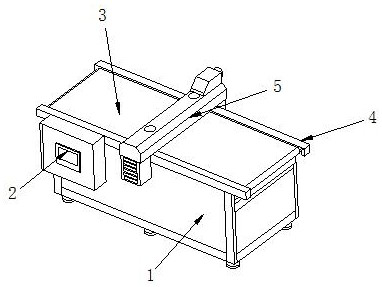

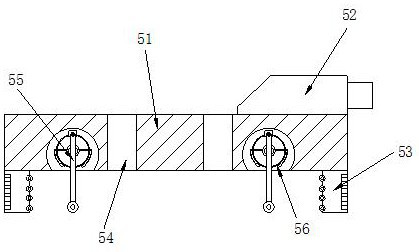

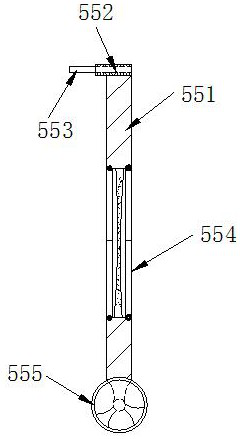

[0026] see Figure 1-Figure 6 , the specific embodiments of the present invention are as follows: an automatic light carton production transmission equipment, its structure includes a base box 1, a control box 2, a conveying platform 3, a card frame 4, a cardboard leveler 5, the front of the base box 1 and The back of the control box 2 is welded and connected, the bottom surface of the conveying table 3 is fixedly connected to the top surface of the base box 1, the inner layer of the card frame 4 is movable and engaged with both sides of the console 2, and the inner layer of the cardboard leveler 5 is connected to the card frame 4. The outer layers are stacked together; the cardboard leveler 5 includes a top block 51, a control machine 52, a moving block 53, an observation vent 54, a leveling rod 55, and a lower feeder 56, and the bottom surface of the top block 51 is in contact with the mobile The top surface of the block 53 is welded and connected, the bottom surface of the ...

Embodiment 2

[0033] see Figure 1-Figure 2 , Figure 7-Figure 8 , the specific embodiments of the present invention are as follows: an automatic light carton production transmission equipment, its structure includes a base box 1, a control box 2, a conveying platform 3, a card frame 4, a cardboard leveler 5, the front of the base box 1 and The back of the control box 2 is welded and connected, the bottom surface of the conveying table 3 is fixedly connected to the top surface of the base box 1, the inner layer of the card frame 4 is movable and engaged with both sides of the console 2, and the inner layer of the cardboard leveler 5 is connected to the card frame 4. The outer layers are stacked together; the cardboard leveler 5 includes a top block 51, a control machine 52, a moving block 53, an observation vent 54, a leveling rod 55, and a lower feeder 56, and the bottom surface of the top block 51 is in contact with the mobile The top surface of the block 53 is welded and connected, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com