Film drawing device

A film device and film sandwich technology, applied in the directions of transportation and packaging, winding strips, sending objects, etc., can solve the problems of continuous film cutting, poor experience, and film jamming, so as to improve production efficiency and improve user experience. Excellent, fast and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

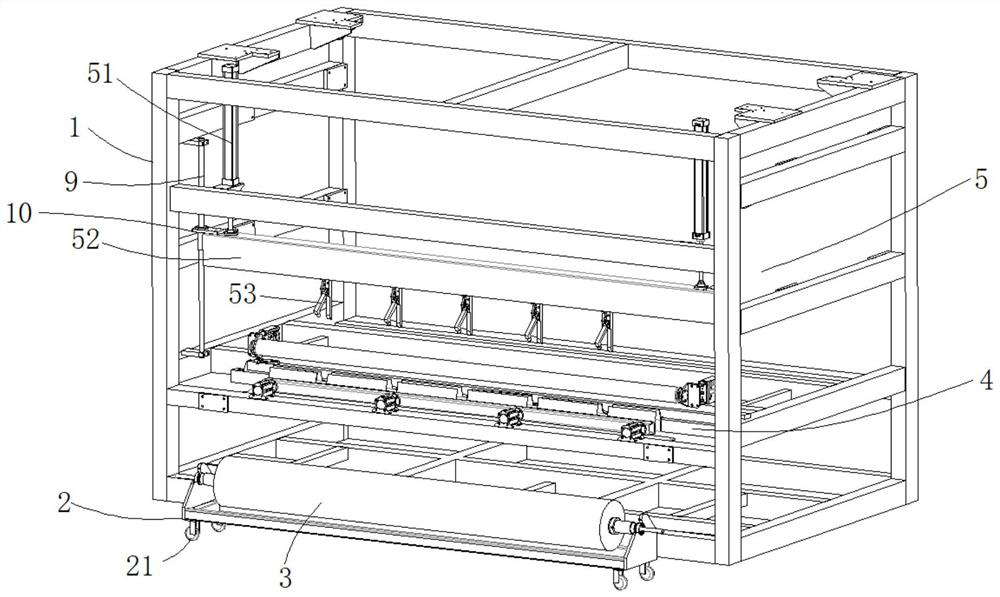

[0018] A film pulling device of the present invention is described with reference to the accompanying drawings.

[0019] Such as Figure 1-Figure 2 Shown, as a kind of preferred embodiment of the present invention:

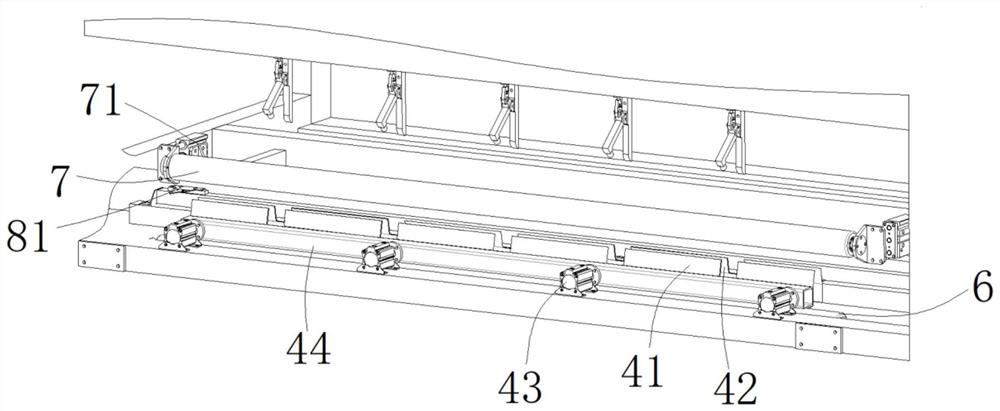

[0020] A film pulling device, comprising: a frame 1; a film frame 2, the film frame 2 is arranged on one side of the frame 1 and is arranged close to the bottom of the frame 1, on the film frame 2 The film release shaft 3 is installed, and the film release shaft 3 is used to place the film; the film clamping mechanism 4, the film clamping mechanism 4 is located above the film frame 2, and the film clamping mechanism 4 includes a first Clamping plate 41 and the second clamping plate 42, the first clamping plate 41 is movably installed on the frame 1, and a clamping film is formed between the first clamping plate 41 and the second clamping plate 42 Passage; Stretching mechanism 5, described stretching mechanism 5 is located at the top of described clamping mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com