Operation platform capable of ascending and descending along cambered surface dome and mounting method thereof

A technology for lifting platforms and working platforms, applied in the direction of lifting devices, etc., can solve problems such as inability to meet construction, and achieve the effects of shortening the construction period, running smoothly, and facilitating on-site installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

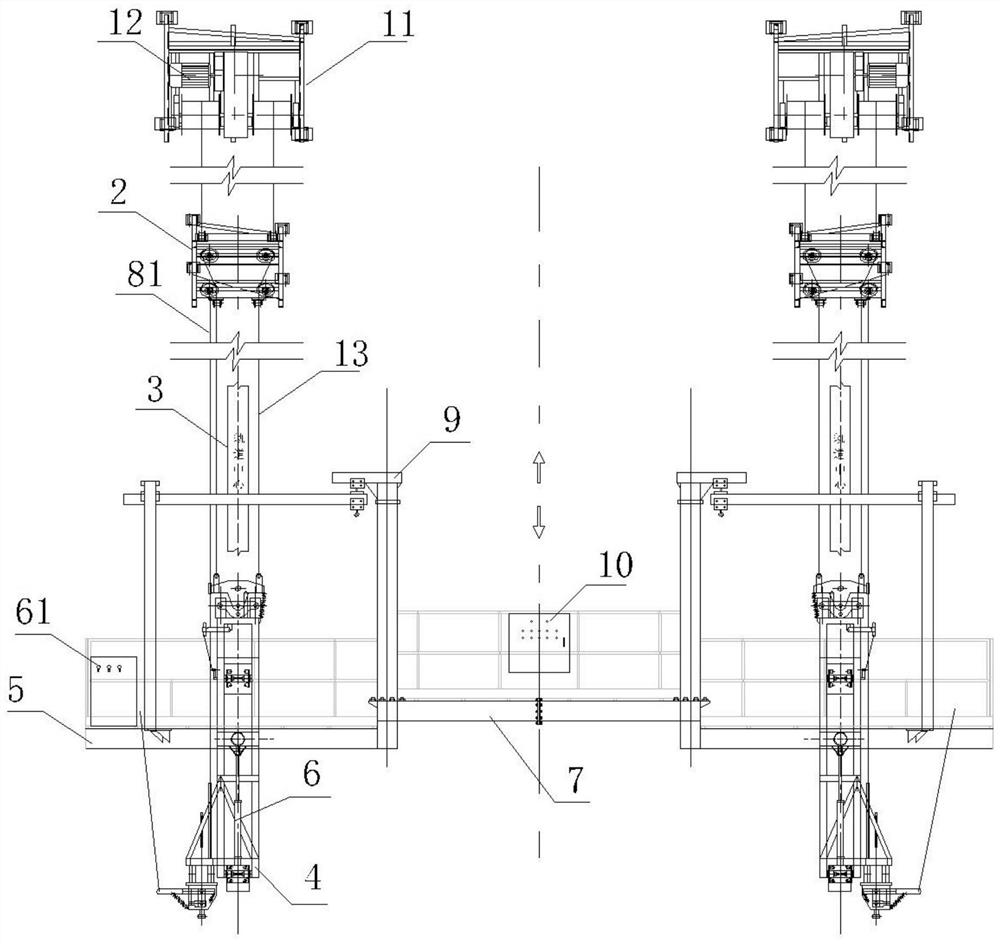

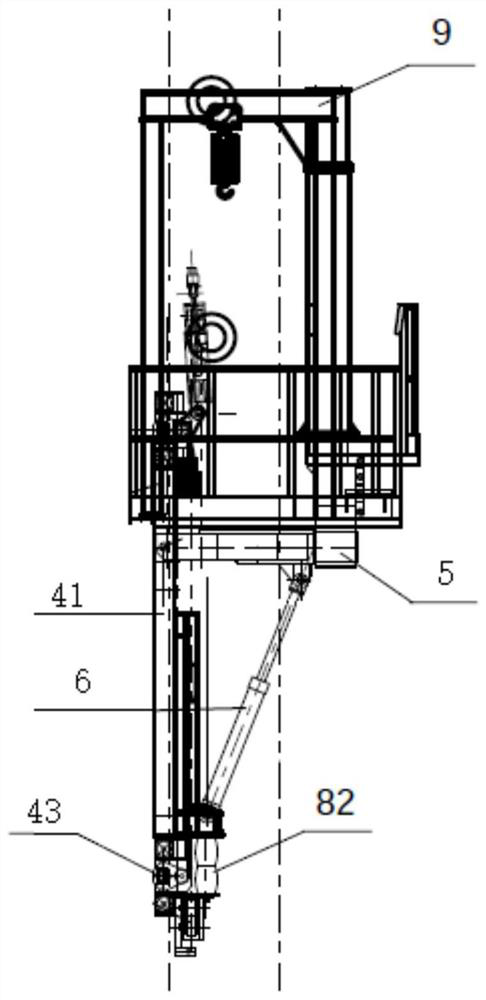

[0029] Such as Figure 1-3b As shown, the present invention provides a working platform that can be raised and lowered along the arc dome, which is arranged outside the containment and includes two lifting units and a connecting platform 7 .

[0030] Two lifting units are respectively arranged on both sides of the buttress column.

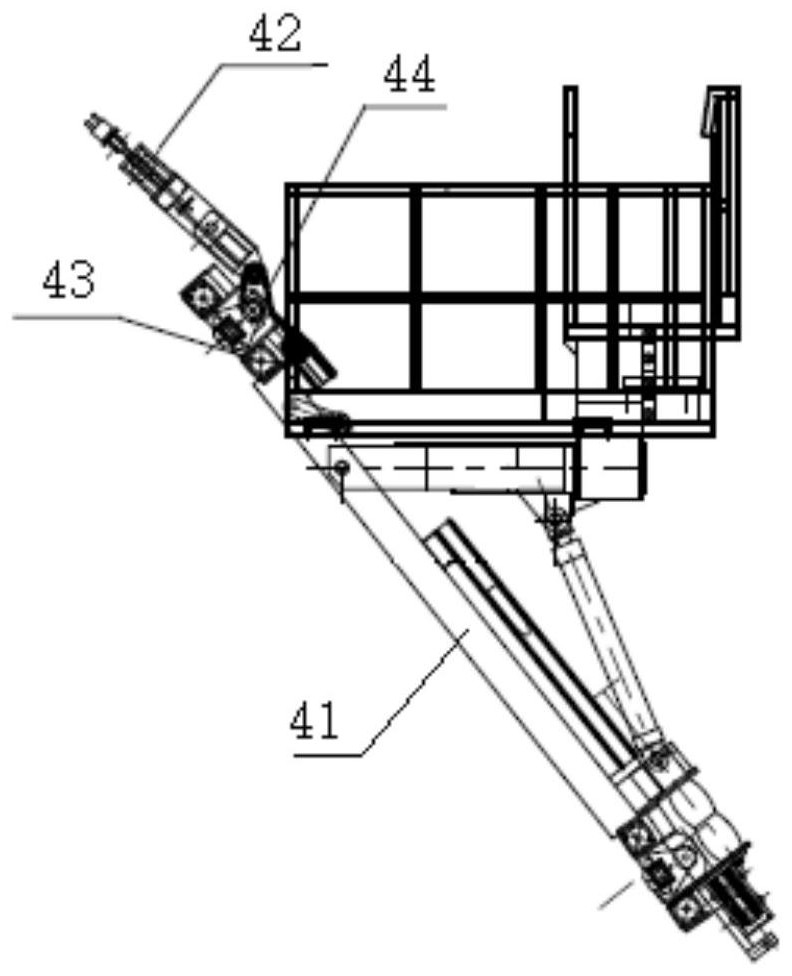

[0031] The lifting unit includes a winch support 11, a winch 12, a rope guide frame 2, several sections of guide rails 3, a climbing assembly 4, a lifting platform 5 and a jacking cylinder 6.

[0032] Wherein, the winch support 11 is a steel structure support, which is welded and fixed on the embedded part of the containment dome. The winch 12 is fixedly installed on the winch support 11 by bolts, and the winch 12 is equipped with two hoisting wire ropes 13 .

[0033] The rope guide frame 2 is fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com