A kind of production fermentation method of microbial fertilizer

A technology of microbial fertilizer and fermentation method, applied in the field of microbial fertilizer production, can solve problems such as poor fermentation effect, and achieve the effects of promoting pulverization, improving utilization rate and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] like Figure 1-4 As shown, a production fermentation method of microbial fertilizer, comprising the following steps:

[0034] S1 feed, after the microbial biomass raw material and fertilizer are adjusted in terms of moisture content and carbon-nitrogen ratio, they are transported into the feed funnel 11;

[0035] S2 grinding, grinding and crushing a variety of microbial raw materials and fertilizers with different particle sizes, to a particle size range of 12mm-60mm;

[0036] S3 mixed fermentation, the microbial biomass raw materials and fertilizers after grinding and crushing are sent to the fermentation tank for fermentation, the temperature is maintained in the range of 35-40 °C, and the heap is continuously turned and ventilated;

[0037] S4 discharging, the microbial fertilizer after fermentation is discharged from the discharging pipe 22, granulated and packaged and transported to the finished product area;

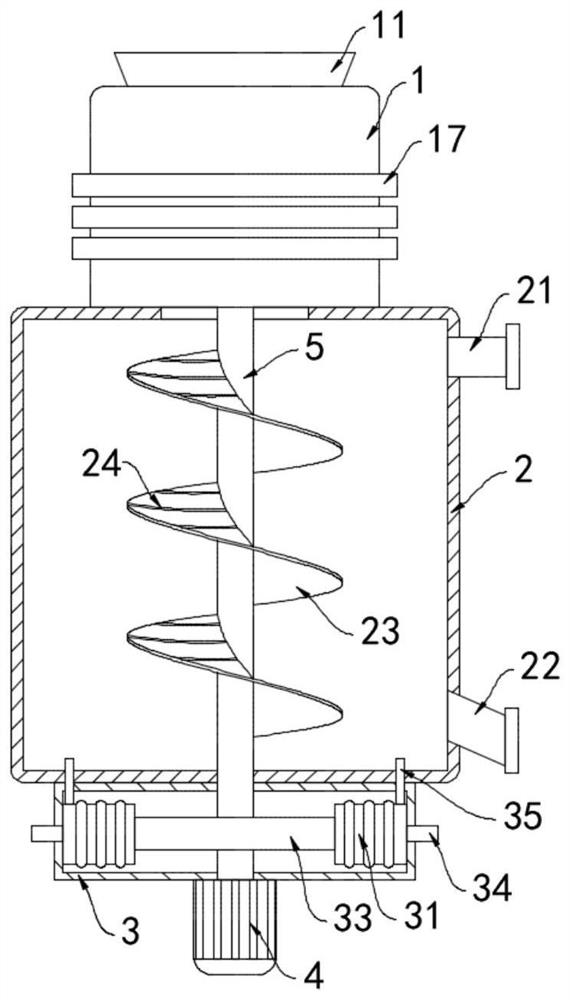

[0038] The fermentation device used in the above-men...

Embodiment 2

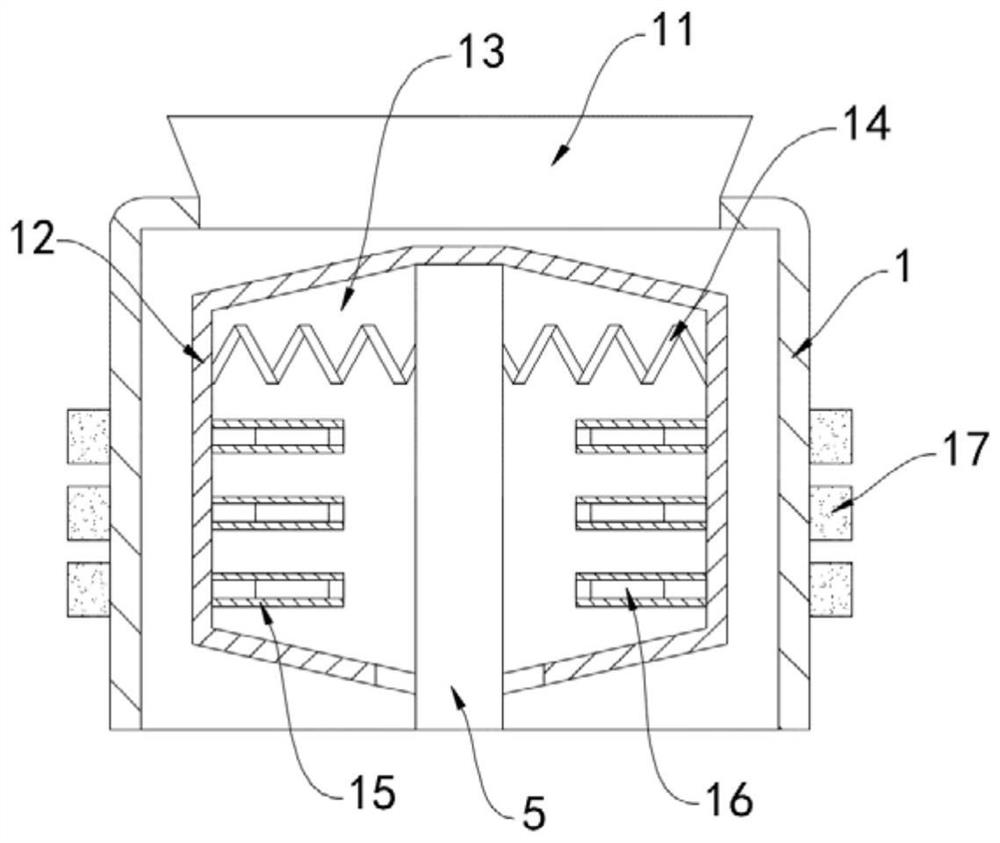

[0046] like Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: the grinding shell 1 is wound with a spiral coil 6, and the winding direction of the spiral coil 6 is perpendicular to the direction of the magnetic induction line of the bar magnet 16, and the grinding shell 1 A heating wire 7 is embedded inside, and the heating wire 7 and the helical coil 6 are coupled and linked.

[0047] In this embodiment, during the rotation of the bar magnet 16 , the helical coil 6 continuously cuts the magnetic field lines of the bar magnet 16 to generate an induced current, which supplies power to the heating wire 7 and preheats the microbial fertilizer in the grinding housing 1 , shorten the heating cycle of the microbial fertilizer in the early stage of fermentation, and improve the fermentation efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap