Offshore wind power foundation comprising single column and negative pressure cylinder and provided with dense beams at top of cylinder and separated bins in cylinder

A technology of offshore wind power and negative pressure cylinders, which is applied in infrastructure engineering, construction, etc., can solve problems such as unfavorable foundation fabrication, transportation and hoisting, buckling damage, and high project cost, so as to avoid offshore piling and rock-socketing operations and enhance resistance The ability of buckling instability and the effect of reducing the cost of foundation engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

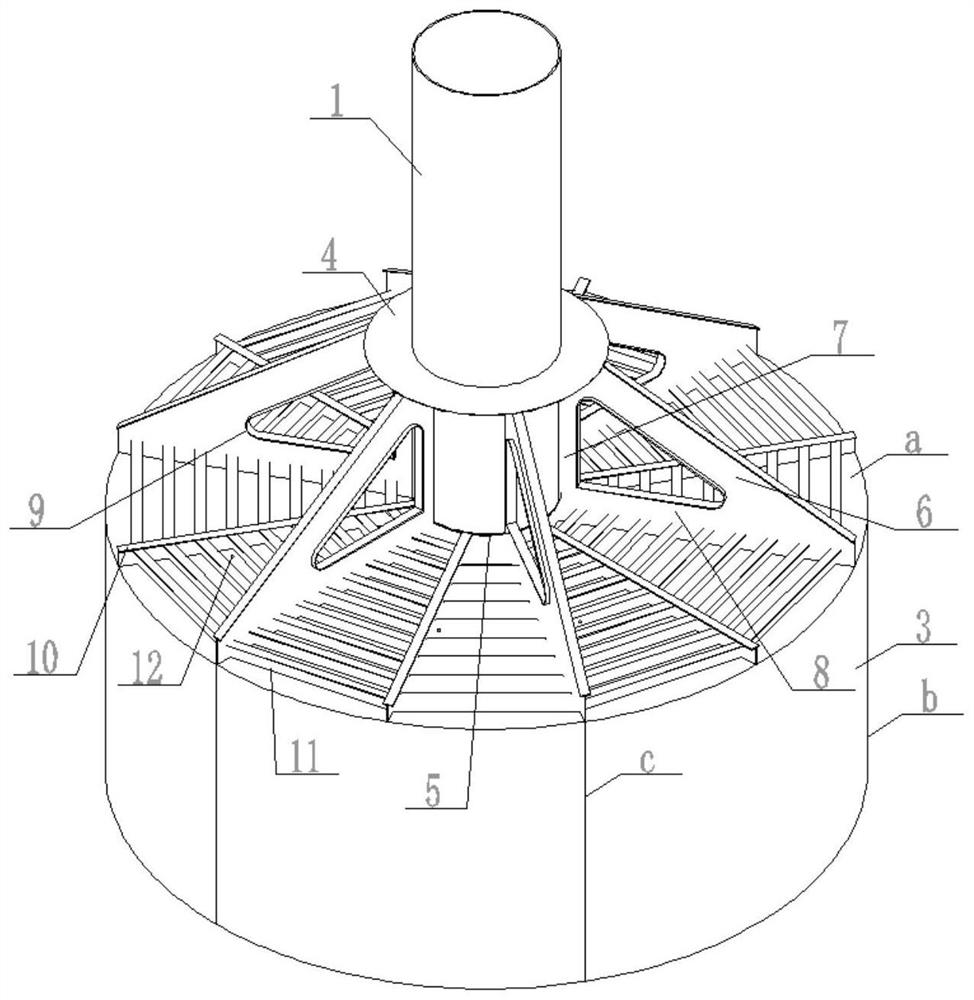

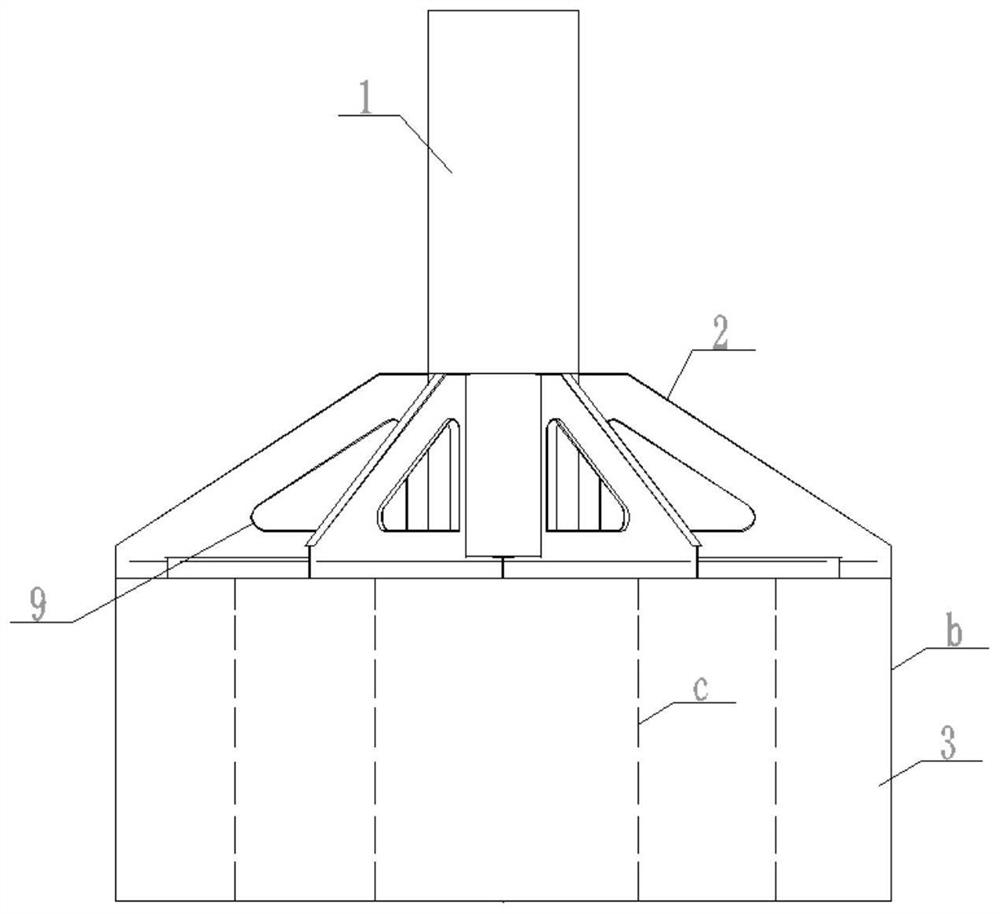

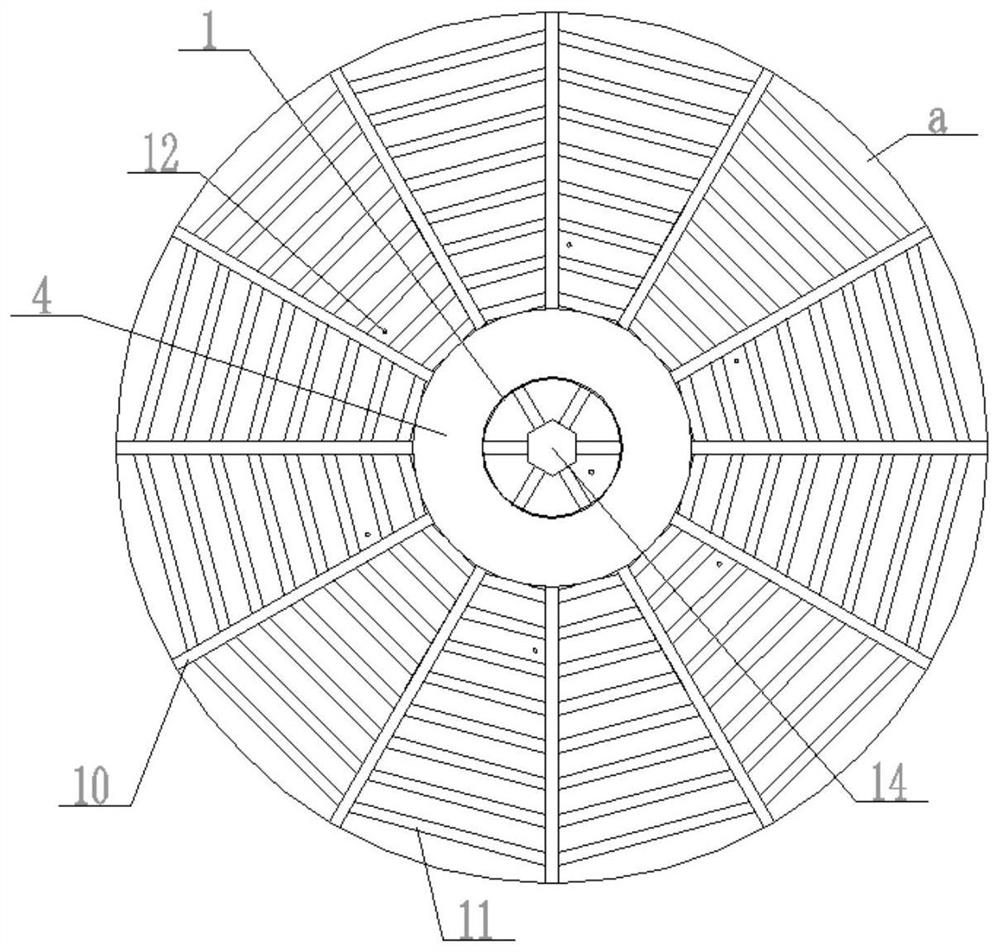

[0034] Such as Figure 1-7 As shown, the offshore wind power foundation of the present invention is a single-column negative-pressure cylinder with a single-column negative-pressure cylinder, which includes a single-column 1 and a negative-pressure cylinder. The single-column 1 is arranged vertically. The bottom is fixedly connected with the top plate a of the negative pressure cylinder 3. The single column 1 is fixedly connected to the negative pressure cylinder 3 through the diagonal support 2, and the diagonal support 2 is fixedly connected to the top plate a of the negative pressure cylinder 3 to form a whole, and the load borne by the single column 1 is effectively transferred to the negative pressure cylinder 3. The present invention utilizes the negative pressure system to discharge the water and gas in the negative pressure cylinder 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com