Plug valve durability test fixture

A technology for testing fixtures and plug valves, applied in the field of plug valves, can solve problems affecting the test structure, achieve accurate and effective data, and solve the effects of self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

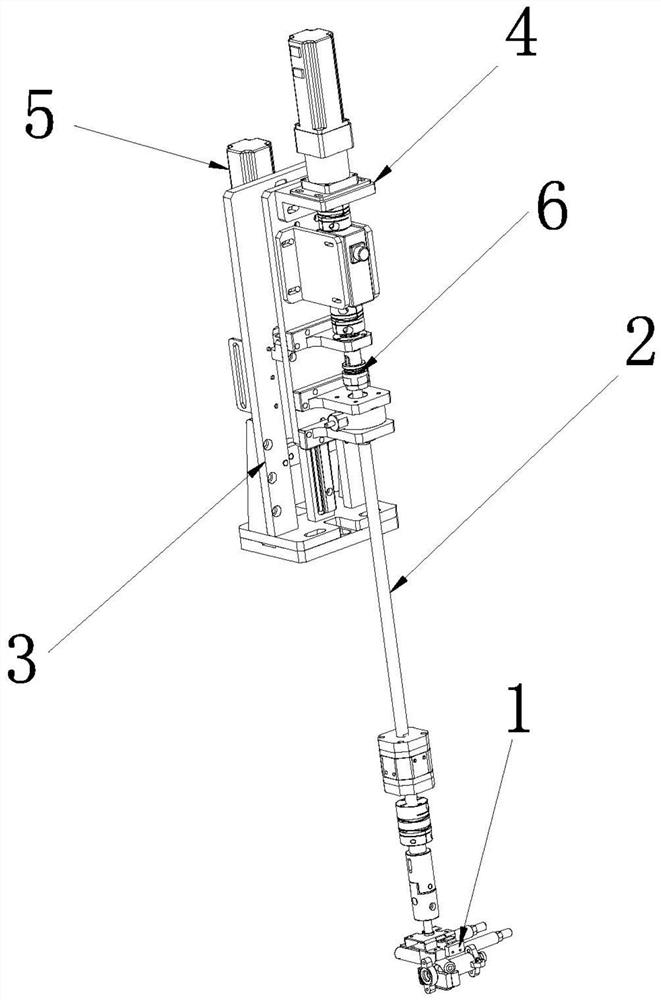

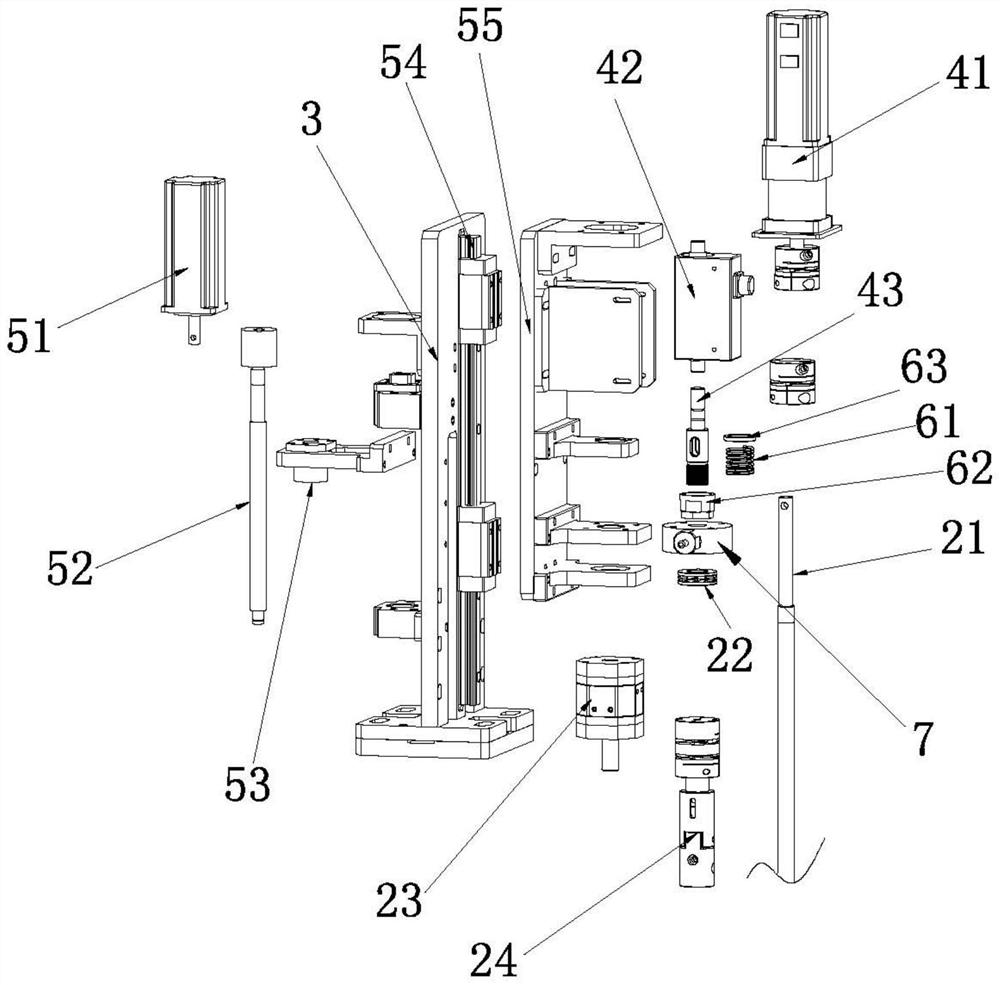

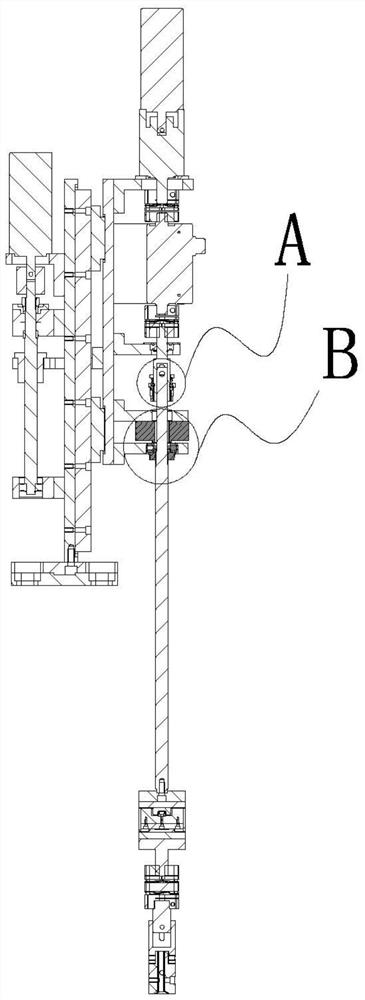

[0025] For a specific implementation of a plug valve durability test fixture of the present invention, please refer to Figure 1 to Figure 3 , the fixture includes a mounting base 3 , a rotating rod assembly 4 and a driving mechanism 5 for driving the rotating rod assembly 4 to reciprocate up and down along the mounting base 3 . The driving mechanism 5 includes a servo motor 51 , a screw mandrel 52 , a screw mandrel nut 53 , a slide rail 54 and a slide plate 55 . The servo motor 51 is fixedly installed on one side of the mounting base 3, and the other side of the mounting base 3 is fixedly equipped with a slide rail 54. The output shaft of the servo motor 51 is fixedly connected to the screw rod 52, and the screw nut 53 is sleeved on the screw rod 52. Above, the screw nut 53 is fixedly connected with the slide plate 55 , the slide plate 55 is connected with the slide rail 54 , and the rotating rod assembly 4 is fixedly installed on the slide plate 55 . The transmission mode i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com