Dynamic inspection equipment for engine mechanical overspeed protection device

A technology of overspeed protection and dynamic inspection, applied in the direction of engine testing, measuring devices, devices using electric/magnetic methods, etc., to achieve the effects of shortened detection time, reduced maintenance costs, and low personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be described in detail below in conjunction with specific embodiments.

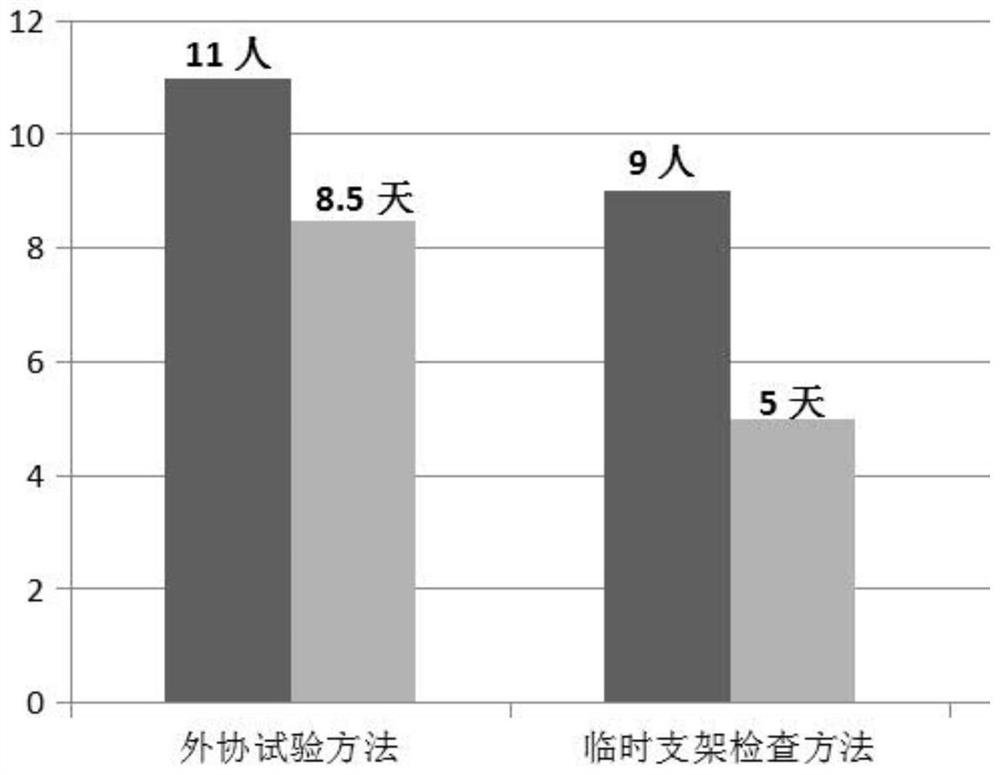

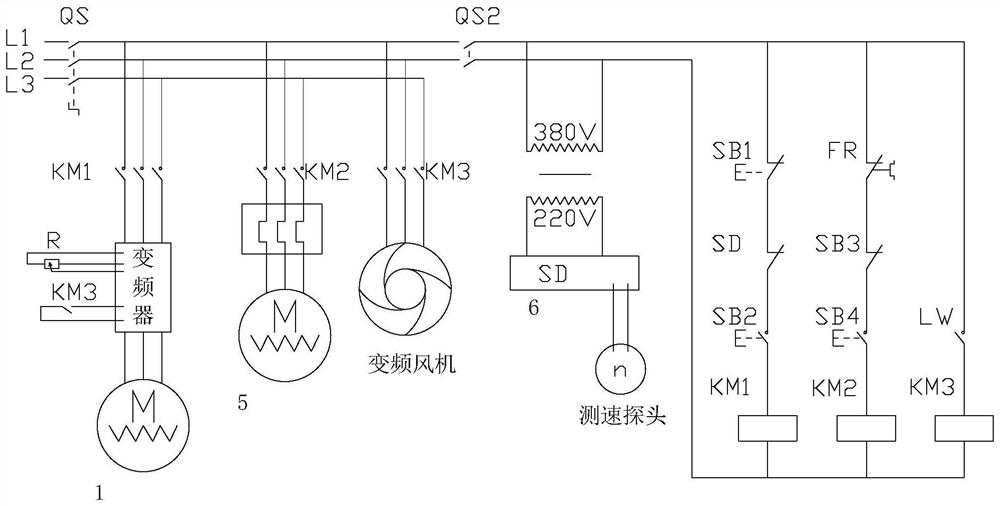

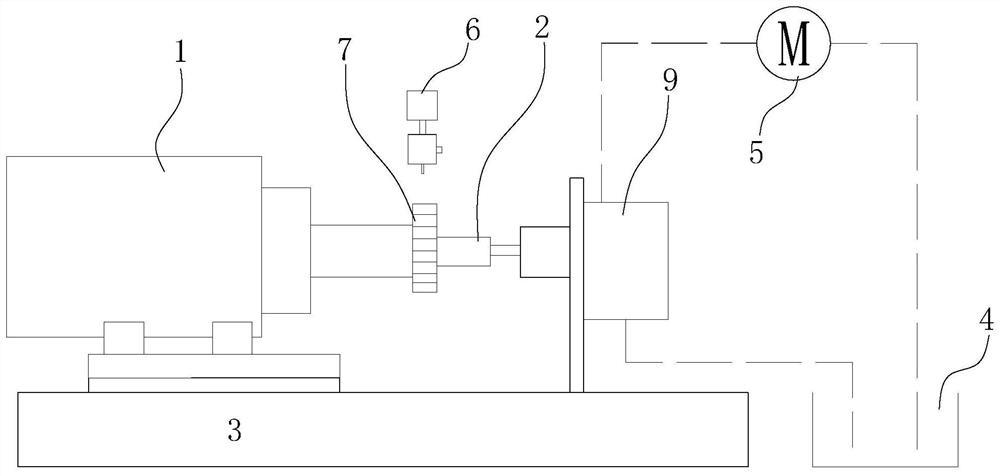

[0022] A dynamic inspection device for an engine mechanical overspeed protection device of the present application is mainly used for dynamic inspection of the engine overspeed protection device during maintenance. For the production and maintenance enterprises of overspeed protection devices, the temporary bracket inspection method is generally adopted. It takes a lot of time to complete the test by outsourcing the test. It takes a lot of time in the joints of the enterprise, the test process and the travel. It often requires a large number of execution and cooperation personnel, which is inefficient. , the speed cannot be guaranteed. Using the temporary support inspection method requires the construction of temporary support, motors and other equipment, and also requires a lot of preparation work. In addition to other work content, the average time and staffing requirements of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com