Battery sensor and method for producing battery sensor

A battery sensor and battery technology, applied in secondary batteries, electrochemical generators, instruments, etc., can solve the problems of expensive, complicated arrangement and fixing of retaining elements, and complicated battery sensor manufacturing, and achieve reliable support function and reliable connection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

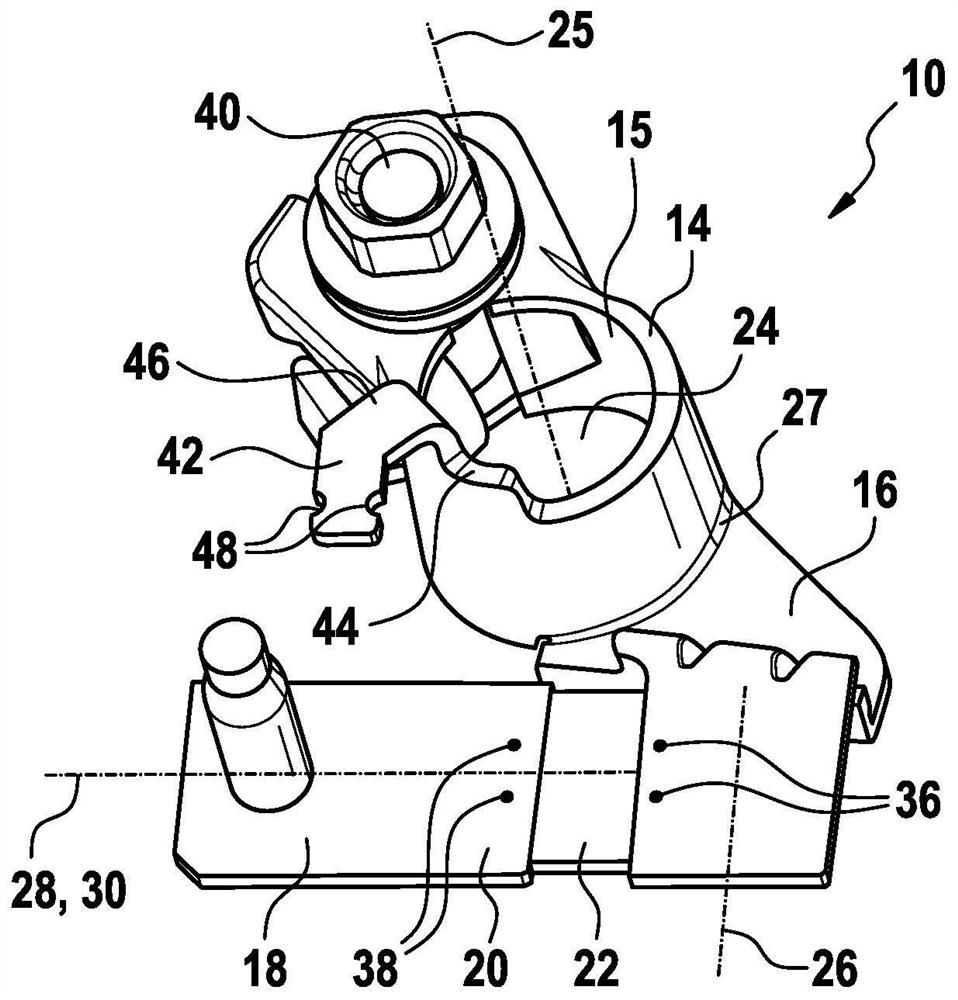

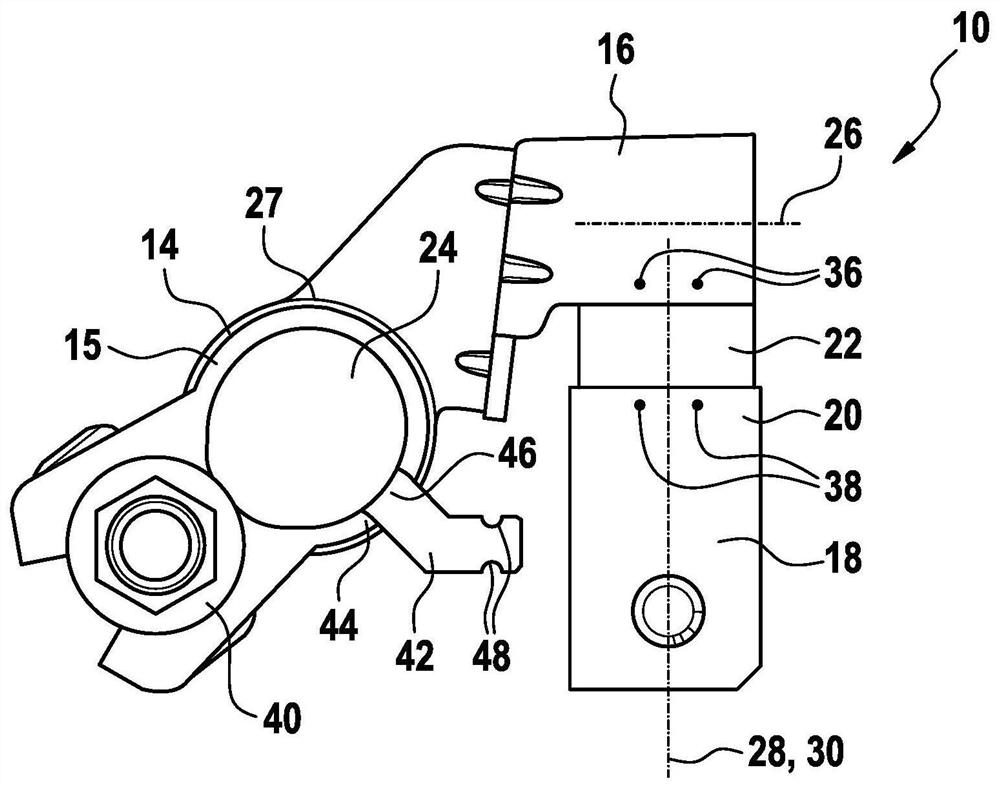

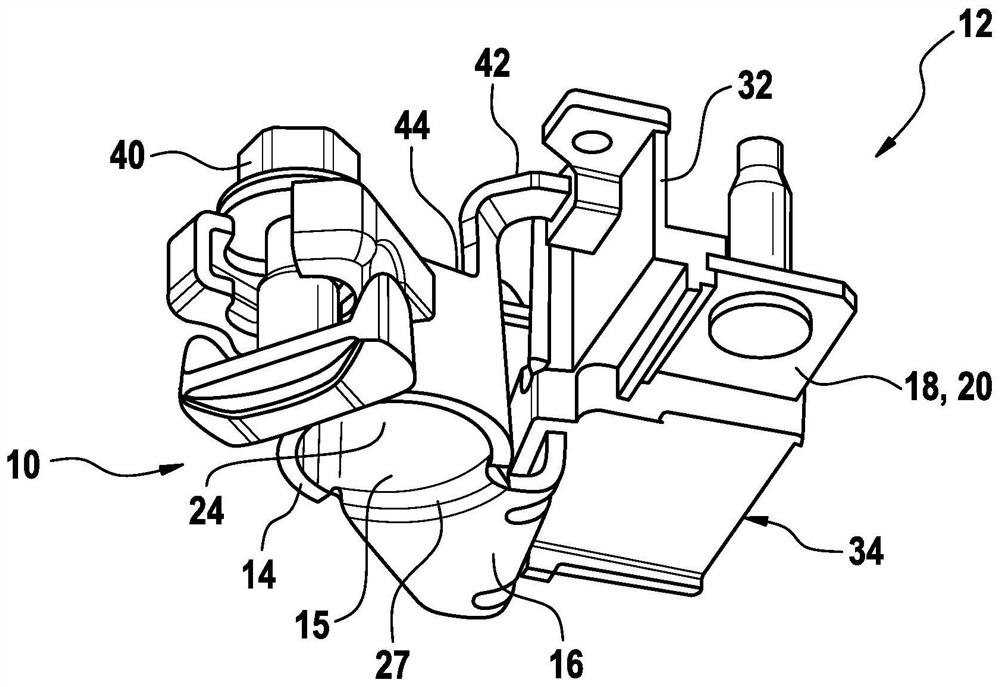

[0032] figure 1 and figure 2 shown for the Figure 3 to Figure 6 The resistor assembly 10 of the battery sensor 12 is depicted in .

[0033] The resistor assembly 10 has a battery terminal 14 with a ring section 15 and a first retention section 16 , and a cable connection 18 with a second retention section 20 . The first retention section 16 and the second retention section 20 , and thus the battery terminal 14 and the cable connection 18 , are electrically and mechanically connected to each other via a measuring resistor 22 .

[0034] In particular, as figure 2 As can be seen in , most of the first retaining section 16 extends radially away from the cylindrical or conical receiving space 24 defined by the battery terminal 14, wherein the first retaining section 14 exist figure 2 is curved in plan view. The longitudinal axis 26 of the first retaining section 16 transitioning into the measuring resistor 22 extends approximately at right angles to the longitudinal axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com