Optical fiber light supply equipment

A technology of optical fiber and optical equipment, applied in the direction of optical guide, optical waveguide coupling, optics, etc., can solve the problems of test optical parameter deviation, blurred light, etc., and achieve the effect of reducing deviation, clear light, and speeding up temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

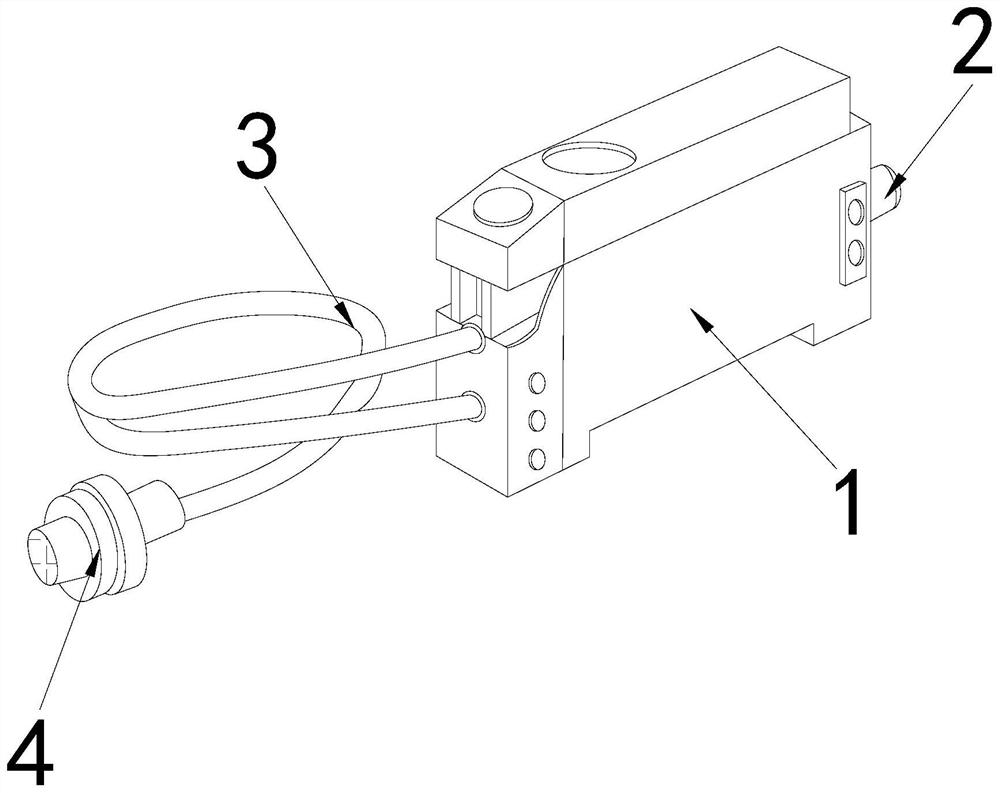

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides an optical fiber light supply device, the structure of which includes an electrical device 1, a port 2, a wire 3, and a photoreceptor 4, the right side of the electrical device 1 is provided with a port 2, and the wire 3 is installed on the electrical device 1 On the left side, the photoreceptor 4 is connected to the end of the photoreceptor 4 .

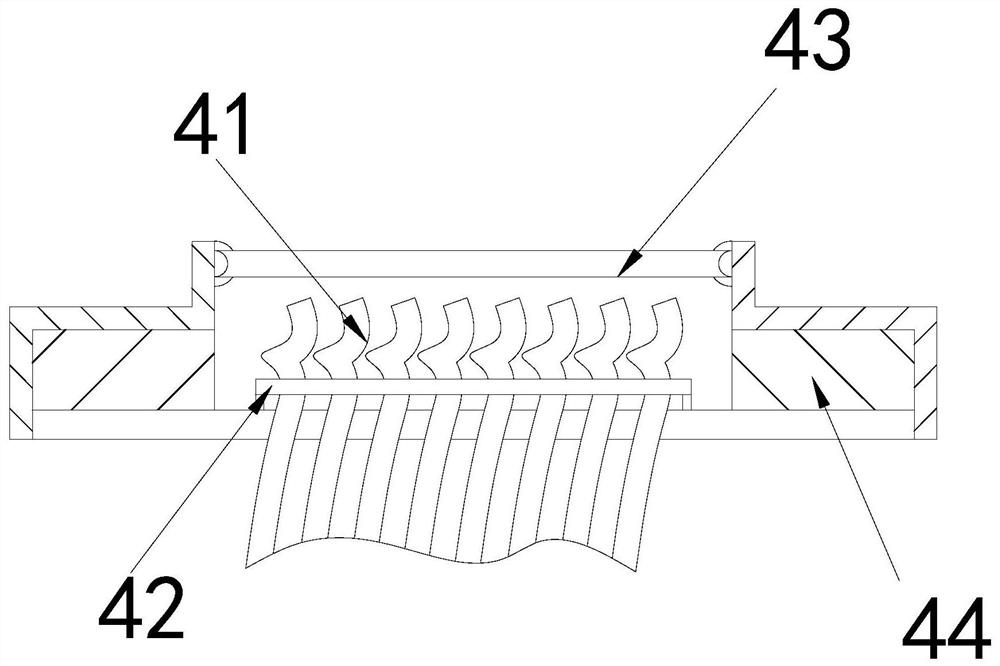

[0027] The photoreceptor 4 is provided with an optical fiber 41, a binding block 42, a lens 43, and a cooling block 44. The optical fiber 41 passes through the bottom of the photoreceptor 4 and is located inside the photoreceptor 4. The binding block 42 is bound on the light guide Outside the fiber 41 , the lens 43 is fixed on the top of the middle part of the photoreceptor 4 , and the heat dissipation block 44 is located inside the photoreceptor 4 and on both sides of the optical fiber 41 .

[0028] Wherein, the heat dissipation block 44 is pro...

Embodiment 2

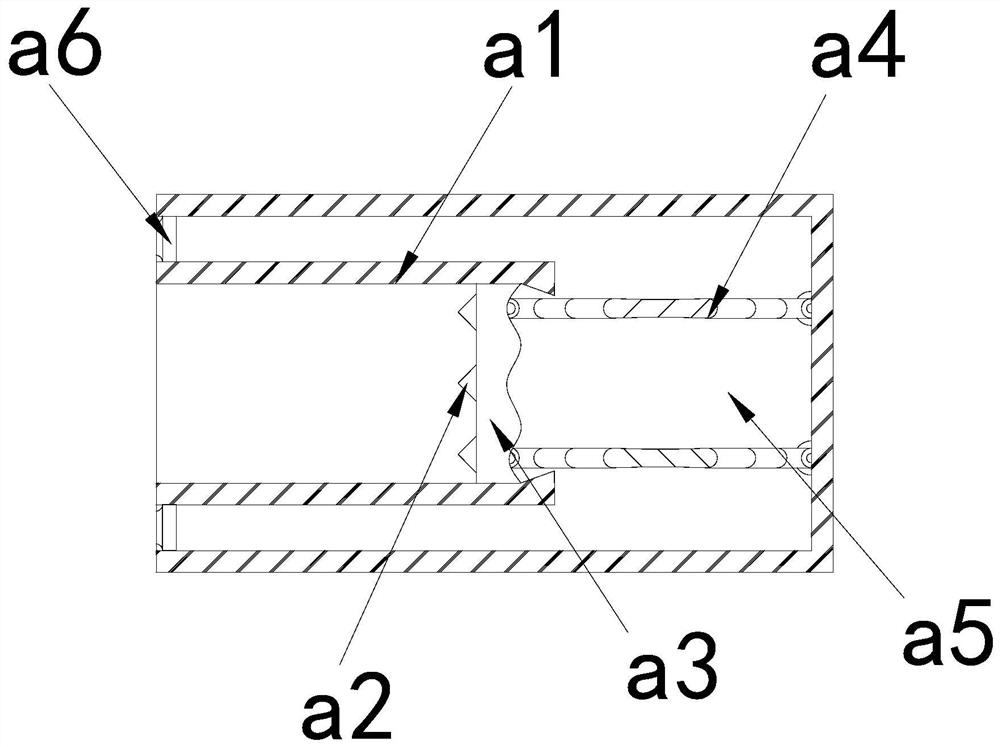

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the air inlet s4 is provided with a side plate n1, a splint n2, an inner cavity n3, a connecting plate n4, an air hole n5, and a push spring n6, the side plate n1 is located on the left side of the air inlet s4, and the splint n2 is installed At the upper and lower ends of the side plate n1, the inner cavity n3 is located inside the air inlet s4, the splint n2 is movably matched through the connecting plate n4, the air hole n5 runs through both sides of the connecting plate n4, and the push spring n6 is clamped in the air hole Between n5, the connecting plate n4 has elasticity, which is beneficial to drive the splint n2 to swing, so that the gas in the inner cavity n3 is pressurized and the impact force of the gas is increased.

[0036]Wherein, the splint n2 is provided with a bottom plate m1, an inner groove m2, a partition m3, and a clamping ball m4. Fixed on the inner wall of the inner groove m2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com