Anaerobic digestion biogas slurry vacuum concentration and recycling method and device

A technology of vacuum concentration and anaerobic fermentation, applied in fertilization equipment, separation methods, anaerobic digestion treatment, etc., can solve the problem of low nutrient concentration, achieve no resource waste, good economic and social benefits, and shorten the time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

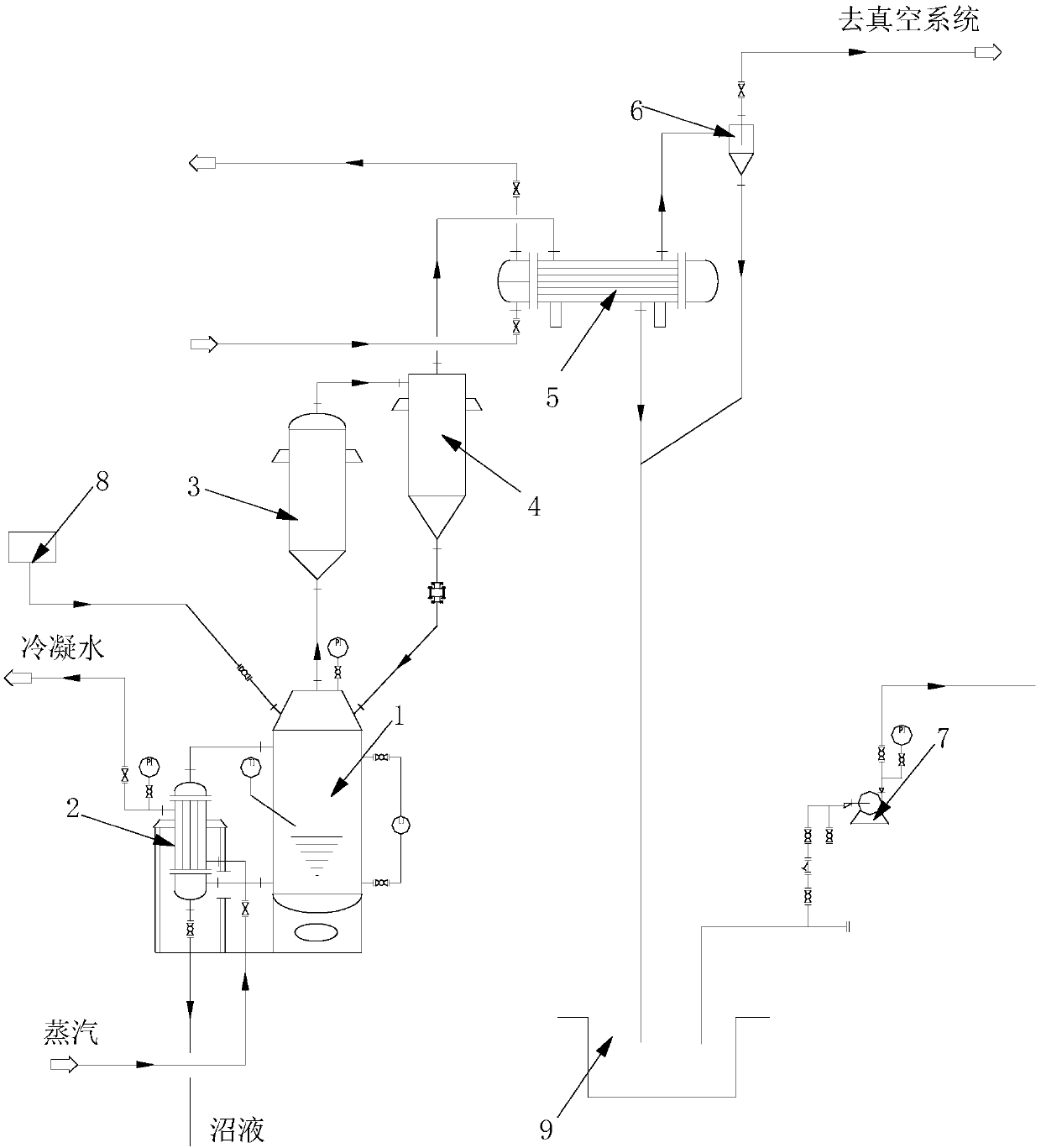

[0027] Such as figure 1 As shown, a vacuum concentration device for anaerobic fermentation biogas slurry includes a purification tower 1, a biogas slurry heater 2, a defoaming tank 3, a buffer tank 4, a biogas slurry cooler 5, a gas-liquid separation tank 6, and a water seal pool 9 , anaerobic fermentation tank 8, the upper part of the purification tower 1 is provided with a raw material inlet, the raw material inlet is connected to the anaerobic fermentation tank 8, the upper part of the purification tower 1 is connected to the top of the biogas slurry heater 2, and the lower part of the purification tower 1 is connected to the top of the biogas slurry heater 2 The bottom of biogas slurry heater 2 is connected, the top of the purification tower 1 is connected to the bottom of the defoaming tank 3; the top of the defoaming tank 4 is connected to the top of the buffer tank 5, and the bottom of the buffer tank 5 is connected to the top of the purification tower 1; The biogas liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com