Fruit picking sequence planning method based on visual selection attention mechanism

An attention mechanism and vision technology, applied in picking machines, harvesters, computer parts, etc., can solve problems such as high labor costs, increased burden, and aggravated robot uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

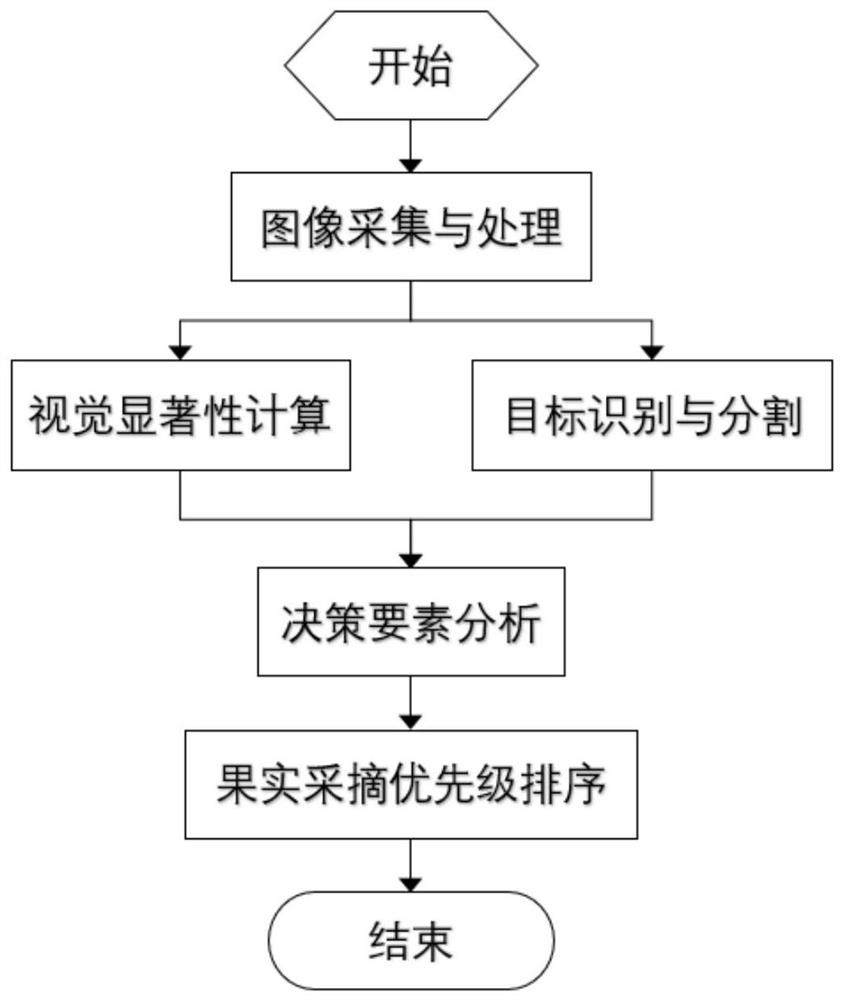

[0076] Such as figure 1 Shown is the operation flow of the fruit picking sequence planning method based on the visual selection and attention mechanism of the present invention.

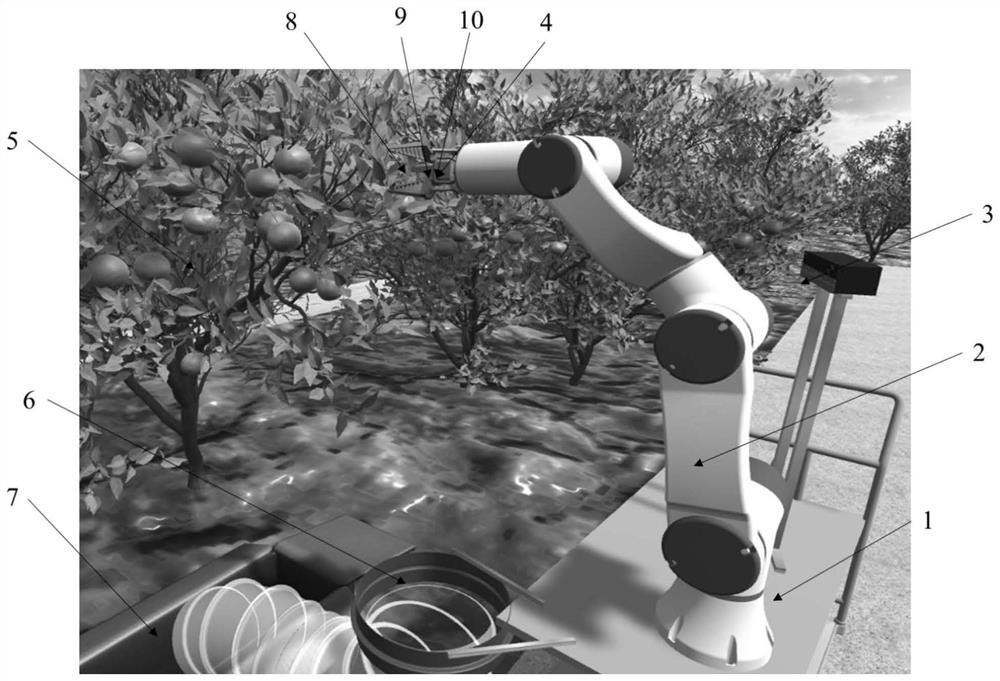

[0077] Such as figure 2 As shown, the fruit picking robot includes a liftable platform 1 , a six-degree-of-freedom robotic arm 2 and a Kinect v2 camera 3 . The picking robot is the elfin series produced by Han's Robot Company, and it is placed in front of the fruit tree 5. The Kinectv2 camera is installed on the left or right side of the center line of the picking robot base, the center of the camera and the center of the picking robot base are kept on the same line, the viewing distance of the camera is 0.5m to 4.5m, and the moving range of the picking robot end is within 0.5m~2m, considering the difficulty of picking fruit trees at different distances, the picking area of the picking robot is limited to an area about 1m~1.5m away from the fruit trees.

[0078] The end effector of the picking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com