Acid water and preparation method thereof

A sour water and total acid technology, applied in the food field, can solve problems such as unstable acid water quality and unstable bean curd product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

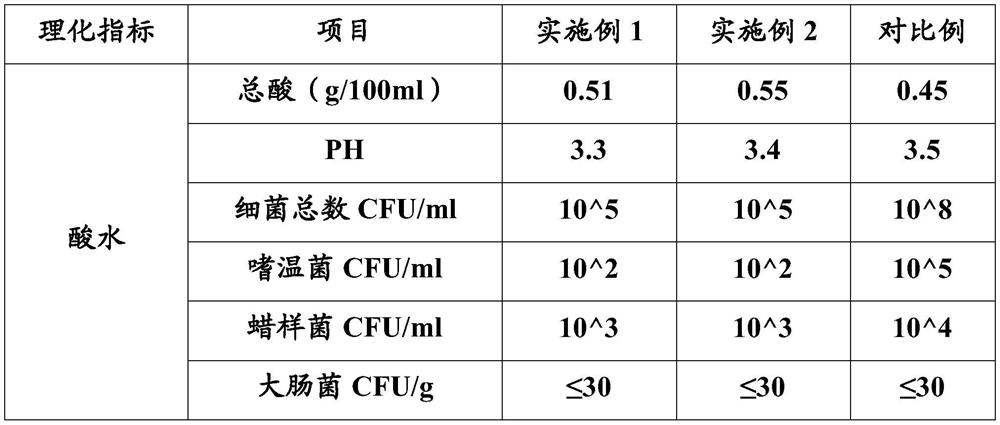

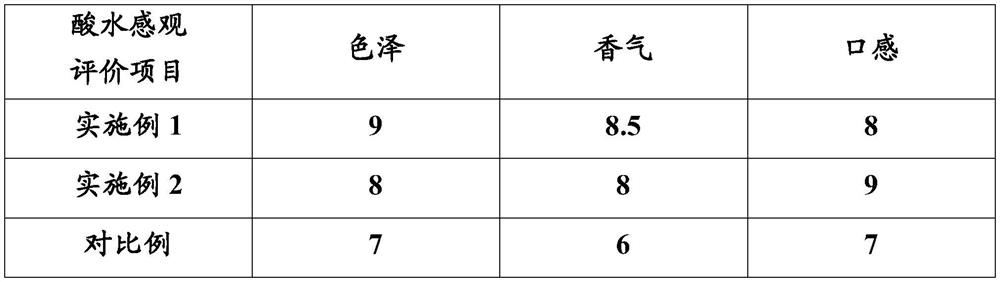

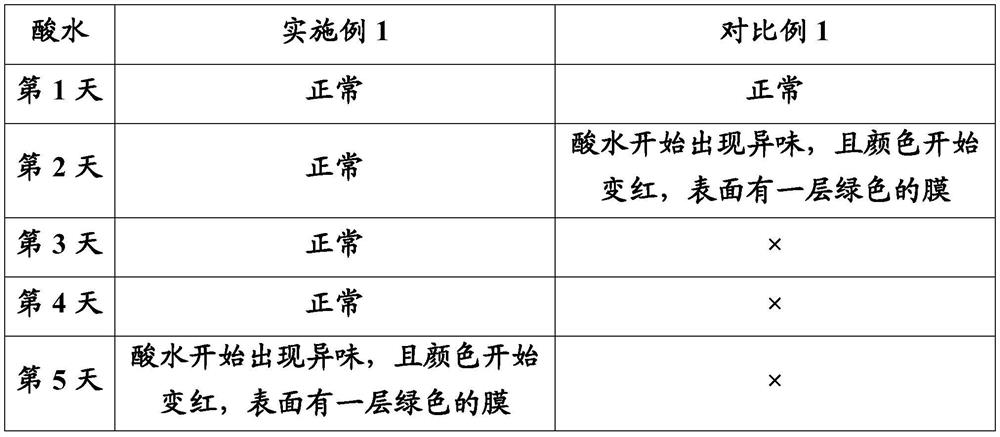

Embodiment 1

[0049] (1) collect the yellow slurry water discharged after pointing slurry in the process of preparing tofu;

[0050] (2) Collect the yellow slurry water into a bucket with a conical bottom, let it settle for 30 minutes, and extract the supernatant formed by the settlement;

[0051] (3) Heat the supernatant to 95°C and keep it warm for 30 minutes;

[0052] (4) Mix the clear liquid and the acid water in a volume ratio of 9:1, stir evenly, the temperature of the mixed product is 75°C, and the total acid is about 0.1g / 100ml.

[0053] The sour seed is prepared in advance, and the preparation method is as follows: the clear liquid is naturally fermented at room temperature (about 20-30°C) for 48 hours until the total acid reaches 0.5g / 100ml, and the sour seed is obtained.

[0054] (5) The product of the previous step was incubated at 75° C. for 48 hours. During the cultivation, the membranes produced on the surface were regularly pulled out. The total acid of the product reached ...

Embodiment 2

[0056] (1) collect the yellow slurry water discharged after pointing slurry in the process of preparing tofu;

[0057] (2) Collect the yellow slurry water into a bucket with a conical bottom, let it settle for 30 minutes, and extract the supernatant formed by the settlement;

[0058] (3) Heat the supernatant to 90°C and keep it warm for 25 minutes;

[0059] (4) Mix the clear liquid and the acid water at a volume ratio of 9:1, stir evenly, the temperature of the mixed product is 75°C, and the total acid is about 0.12g / 100ml.

[0060] The sour seed is prepared in advance, and the preparation method is as follows: the clear liquid is naturally fermented at room temperature (about 20-30°C) for 60 hours until the total acid reaches 0.55g / 100ml, and the sour seed is obtained.

[0061] (5) The product of the previous step was incubated at 80° C. for 60 hours, and the membranes produced on the surface were regularly pulled out during the cultivation process. The total acid of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com