Preparation method of barley vinegar

A technology of barley and barley powder, which is applied in the field of food processing, can solve the problems of weak aroma of finished vinegar, complicated preparation methods, and difficult control of the process, and achieve the effects of strong sour taste, simple preparation method, and easy control of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 A preparation method of barley vinegar

[0036] A preparation method of barley vinegar, carried out according to the following steps:

[0037] ⑴ crushing

[0038] The seed of Job's tears of 100 parts by weight is divided into two parts that are A1 and A2 with a weight ratio of 2:1, A1 is pulverized and then sieved with 30 meshes to obtain Job's tears powder A;

[0039] ⑵ Blending

[0040] Add 5 times the volume of water and 1 part by weight of amylase to A to obtain B after dissolving;

[0041] (3) liquefaction

[0042] Adjust the temperature of B to 85°C, pH to 7.0, and keep it warm for 20 minutes to obtain C;

[0043] ⑷Saccharification

[0044] Add 0.10 parts by weight of glucoamylase to C, and the koji material obtained from A2 after making koji with 0.5 parts by weight of composite strains, and saccharify at 65°C for 30 minutes to obtain D;

[0045] Among them, the composite bacteria are composed of Aspergillus niger, Aspergillus oryzae and Rhizopus...

Embodiment 2-5

[0063] Example 2-5 The preparation method of barley vinegar

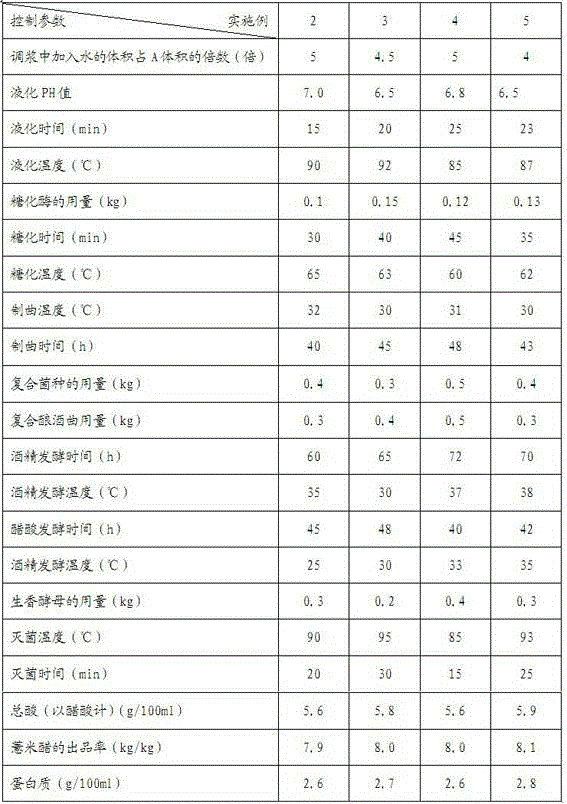

[0064] Examples 2-5 are respectively a preparation method of barley vinegar. The preparation steps are the same as in Example 1, and the total weight of barley used is 100kg. The only difference between them is the control parameters in the corresponding steps. The specific results are shown in Table 1:

[0065] Table 1 Related control parameters in the preparation method of barley vinegar

[0066]

[0067] The acid production rate of barley vinegar prepared in the above examples 2-5 is fast, the output rate is greater than 7.8kg / kg, the total acid (calculated as acetic acid) is greater than 5.5g / 100ml, the protein content is greater than 2.5g / 100ml, and the vinegar aroma is strong , the taste is soft and complex, the taste is mellow, the body is clear, the stability is good, the preservation is easy, the preparation process is easy to control, and the production cycle is short.

Embodiment 6

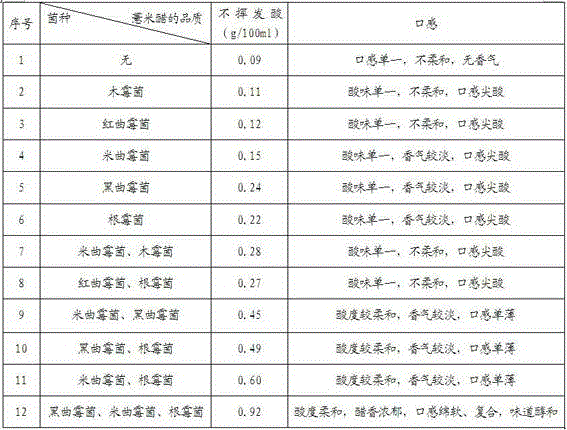

[0068] Example 6 Effects of the Added Types of Composite Bacteria During the Saccharification Process on the Finished Barley Vinegar

[0069] There are two types of total acids in vinegar: volatile acids and non-volatile acids. Volatile acids include formic acid, acetic acid, propionic acid, butyric acid, etc., mainly acetic acid, and few other acids. Acetic acid is the main source of sour taste in vinegar; Volatile acids include lactic acid, succinic acid, gluconic acid, etc., mainly lactic acid, and few other acids. Pure acetic acid is very irritating, has a short aftertaste, and has poor seasoning effect. Only the presence of various organic acids, especially non-volatile acids, can make the sour taste of acetic acid long, soft and delicious. Therefore, vinegar rich in non-volatile acid is less irritating, and has a soft and lingering sour taste. Non-volatile acid is produced by the fermentation of raw materials by complex bacteria, yeast, acetic acid bacteria, lactic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com