Automatic pickup device for extruded tire tread defective products

A bad and automatic technology, applied in the direction of sorting, etc., can solve the problems of increased defective tires, increased production costs, untimely picking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

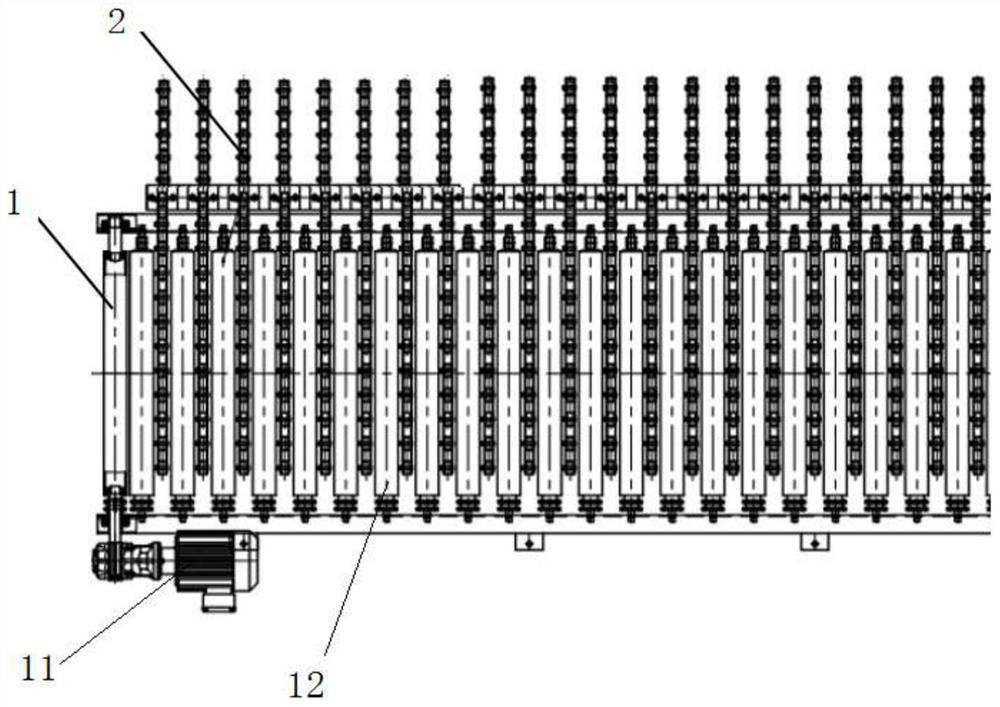

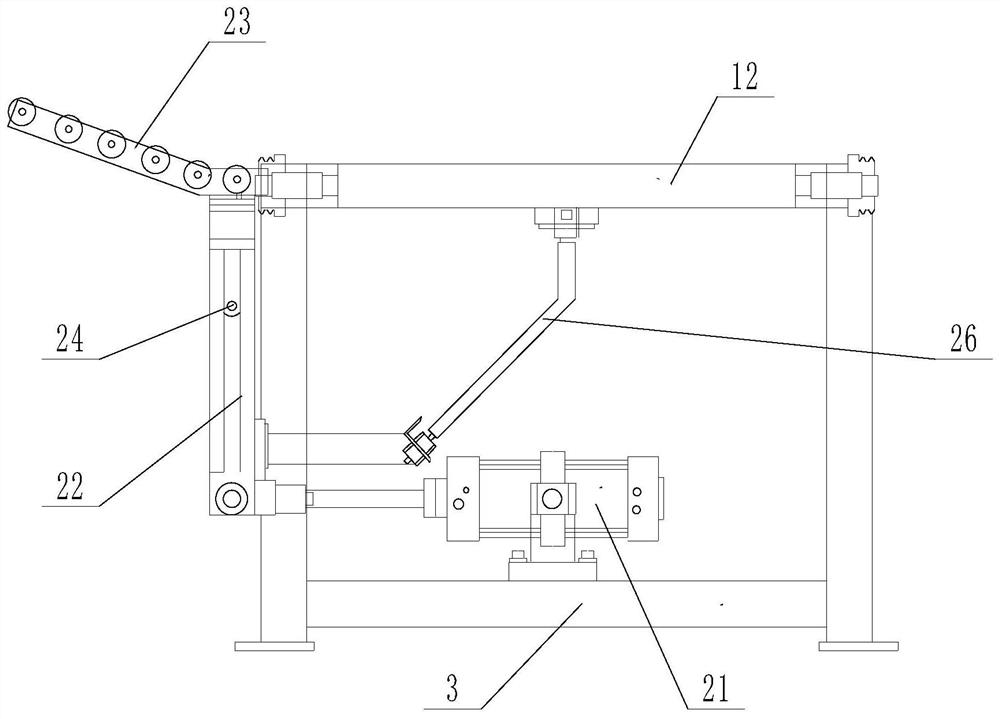

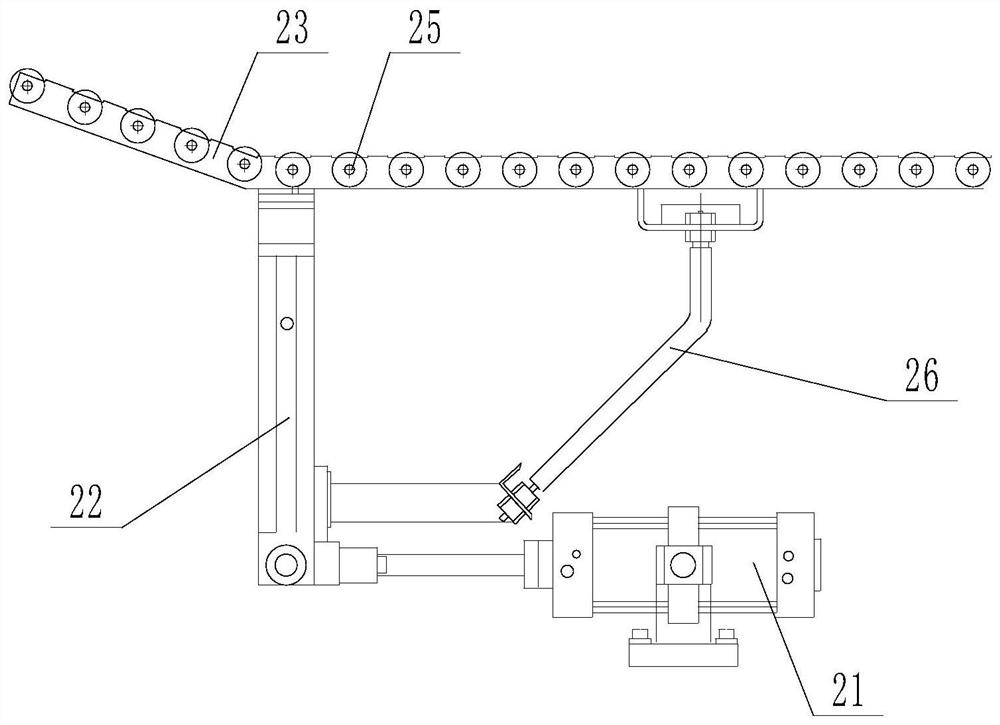

[0028] The automatic pick-up device for defective extruded treads involved in this new model is an addition to the existing extrusion production line (including extrusion equipment, linkage lines, metal detection devices, cutting devices, weight detection devices, and marking devices). The automatic screening device solves the problem of manual selection and omission of defective tread products.

[0029] Such as Figure 7 After the tread is extruded, it is transported through the linkage line, and the distance between the single tread after cutting is passed through the metal detection device and the weight detection device in sequence. The detection information is matched with the standard range set in the device. When the tread is detected When there are metal impurities in the rubber or defective products whose weight exceeds the standard range, the metal detection devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com