A stacking maintenance device for cement board production and its use method

A cement board and curing box technology, which is applied in the stacking, transportation and packaging of objects, ceramic molding machines, etc., can solve the problems of easy water seepage of cement boards, difficulty in reducing the moisture content of cement boards, and shortening the curing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

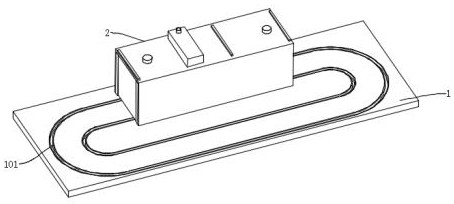

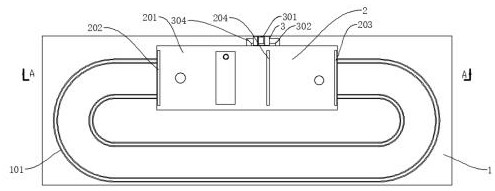

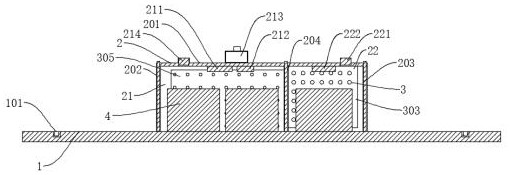

[0038] Such as Figure 1-7 As shown, a stacking maintenance device for the production of cement boards includes a concrete floor 1, and the inside of the concrete floor 1 is connected with a track 101 by screws, and also includes a maintenance mechanism 2, an air pumping mechanism 3, and a stacking mechanism 4. The maintenance mechanism 2 includes a curing box 201, feed door 202, discharge door 203, partition door 204, the curing box 201 is fixed above the concrete floor 1, one side of the curing box 201 is movably connected with the feeding door 202, and the other side of the curing box 201 is movably connected with the discharge The door 203 and the inner side of the curing box 201 are movably connected with a partition door 204, and the upper end of the partition door 204 passes through the curing box 201. The partition door 204 divides the curing box 201 into two chambers, which are respectively the first curing chamber 21 and the curing chamber 201. The second curing cham...

Embodiment 2

[0040] Such as Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the bottom of the support frame 421 is connected with a second magnet 428 by screws, so that the second magnet 428 can be used to adsorb the rotating support leg 425 to realize the rotation of the supporting leg 425. The function of folding.

[0041] A method for using a stacking maintenance device produced by cement boards, comprising the following steps:

[0042] Step 1: When in use, first place the cement board on the top of the support frame 421, and make the cement board vertically placed, then use a sky crane or a forklift to move the entire stacking frame 42 above the mobile trolley 41, and make the support frame 421 The legs are clamped on the inside of the fixing slot 413 until the support plate 411 is filled with the stacking frame 42;

[0043] Step 2: Open the feeding door 202, and start the stacking mechanism 4, so that the stacking mechanism 4 moves to the inside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com