Ultrasonic welding equipment

A technology of ultrasonic welding and equipment, applied in the field of ultrasonic welding equipment, can solve the problems of unstable cycle time, easy misplacement, leakage, manual insertion, etc., to achieve the effect of stable cycle, less error-prone and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

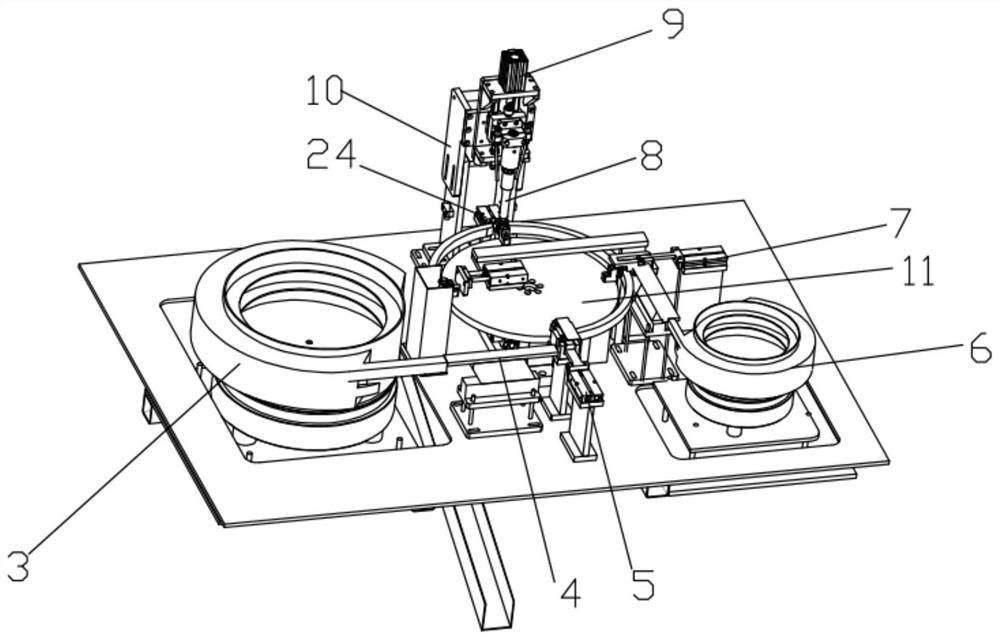

[0021]The following takes the ultrasonic welding of the sheet and the plastic product of Housing as an example to describe the specific implementation and process of the present invention. Unless otherwise specified, all the bodies below correspond to plastic products, and the ligands correspond to sheets. Of course, this welding equipment is not limited to welding such products.

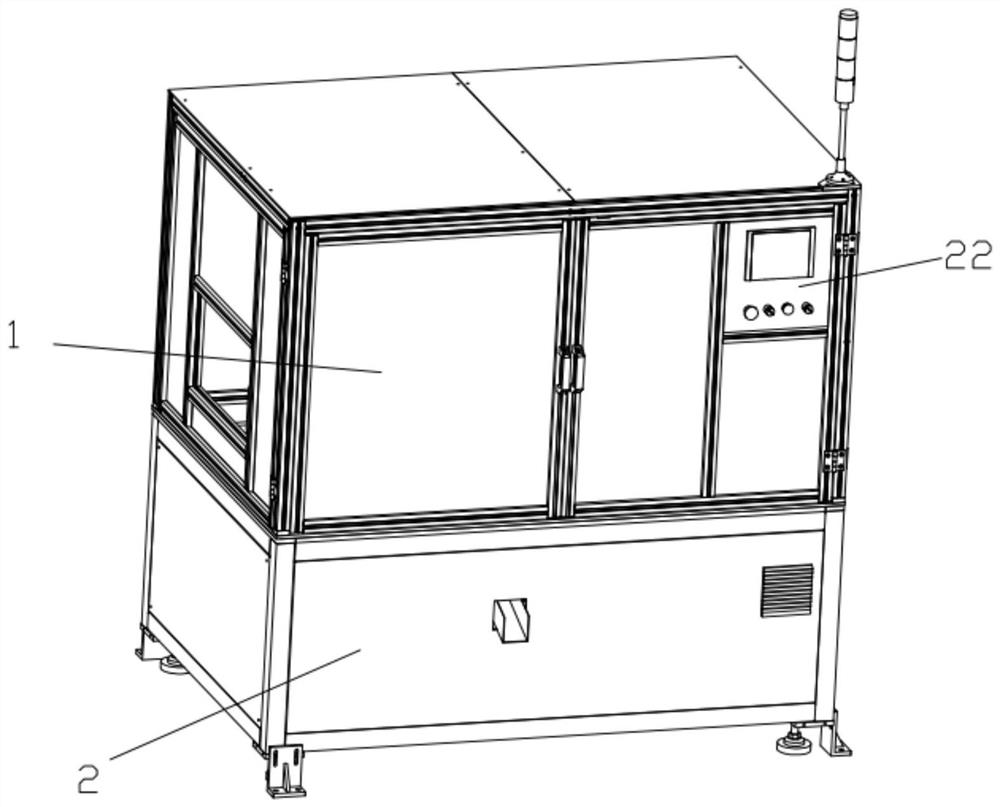

[0022]Such asfigure 1 As shown, the overall shape of the ultrasonic welding equipment invented by the present invention is a box structure, including an upper frame 1 and a lower frame 2. The upper frame 1 is made of aluminum profiles and then installed with a transparent panel. 2 is the lower frame 2 of the square tube, which is enclosed and packaged by square plates.

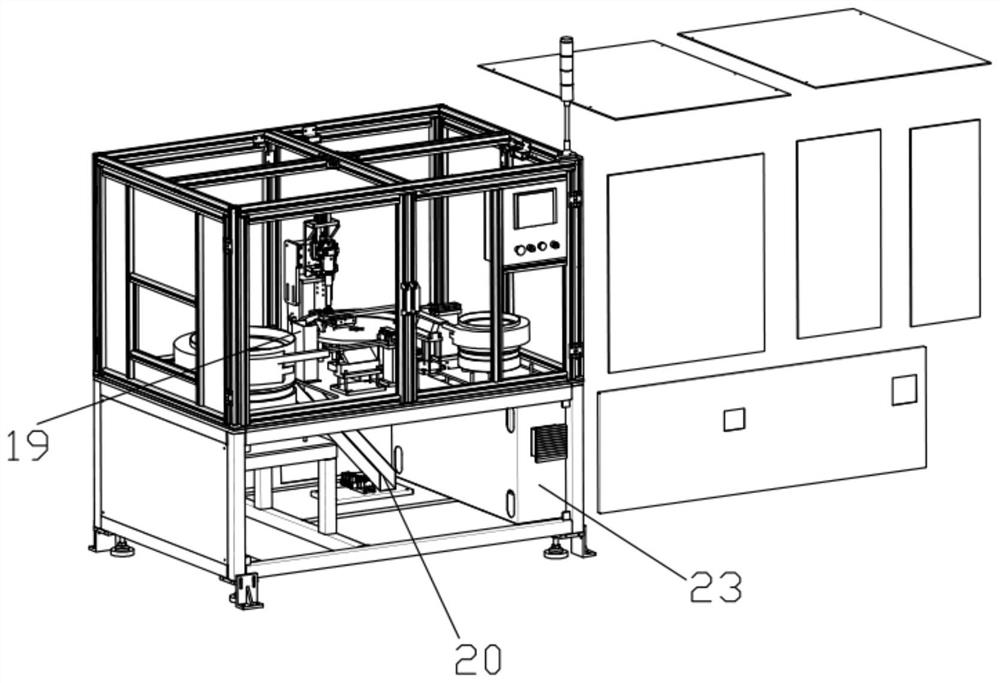

[0023]Combinefigure 1 versusfigure 2 , The upper rack 1 and the lower rack 2 of the ultrasonic equipment are provided with a layer 14 between the upper and lower racks 2 to separate the upper and lower racks 2 into two areas, so that high-power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com