Method, device, equipment and storage medium for monitoring collection efficiency of particulate filter

A particle trap and capture efficiency technology, which is applied in mechanical equipment, electronic control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, etc. The monitoring process is unstable and the results are inaccurate, and the cycle is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

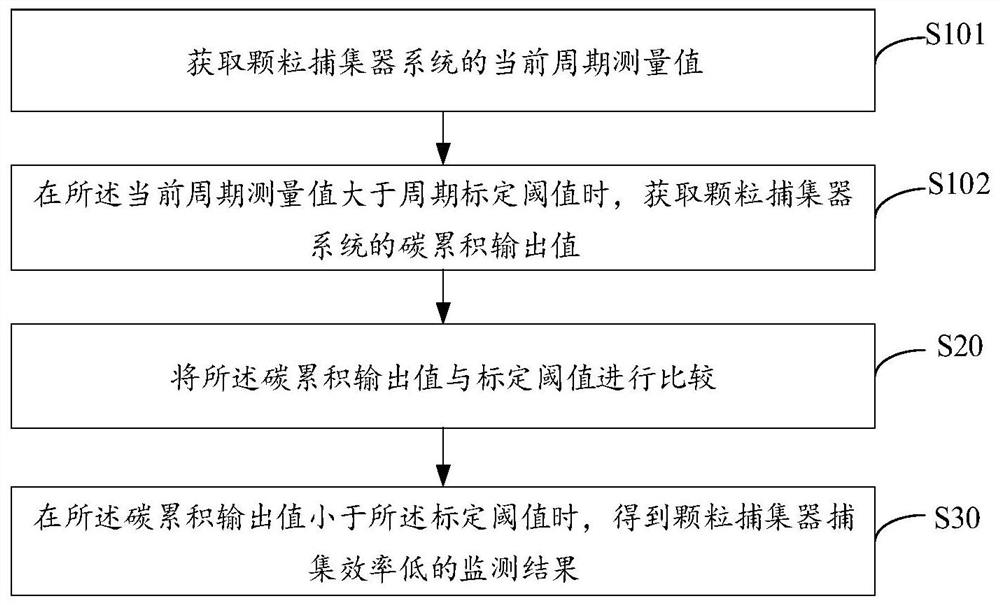

[0068] Based on the first embodiment above, the step S10 of the method for monitoring the collection efficiency of the particle filter in this embodiment includes:

[0069] Step S101: Obtain the current cycle measurement value of the particle trap system.

[0070] It can be understood that the measured value of the current cycle may be the current carbon accumulation amount, or the original carbon emission amount of the engine. The specific acquisition process is: determine the current time, calculate through the preset formula, and determine the measured value of the current period.

[0071] Specifically, in order to obtain an appropriate monitoring period and make the test results more accurate, step S101 includes: obtaining the engine’s original carbon emission accumulation rate; determining the engine’s original carbon emission accumulation rate according to the engine’s original carbon emission accumulation rate and the current accumulation time; The original carbon emis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com