Adsorbent for desorption of heavy metal arsenic, and preparation method and application of adsorbent

An adsorbent and heavy metal technology, applied in separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of inapplicability and limited effect of flue gas dearsenic removal, improve sintering resistance, and enrich surface active sites. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

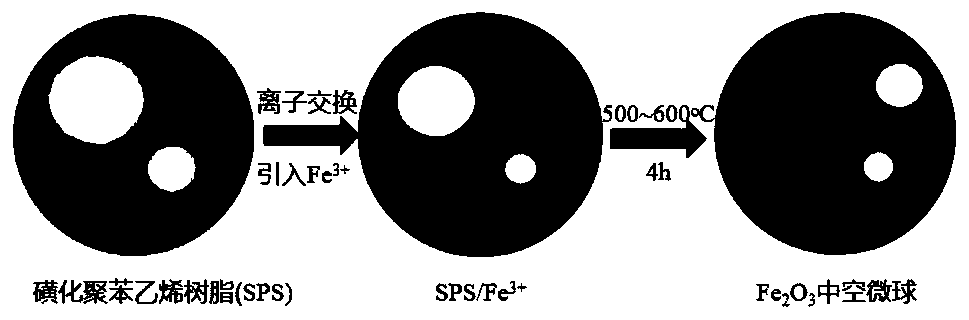

[0023] (2) Preparation of hollow structure iron oxide

[0024] Mix and impregnate the pretreated waste sulfonated polystyrene resin with iron-containing wastewater, and after magnetic stirring for 6-10 hours, filter out the resin, wash and dry; then roast the dried resin at high temperature to obtain hollow iron oxide microspheres ; The diameter of the prepared hollow iron oxide microspheres is generally 0.1-0.5 mm.

[0025] Wherein, the pretreated waste sulfonated polystyrene resin and iron-containing wastewater are mixed and impregnated according to the mass volume ratio of 3-10g:100-200ml. After drying, it is calcined at a high temperature of 500-700°C for 4-6 hours.

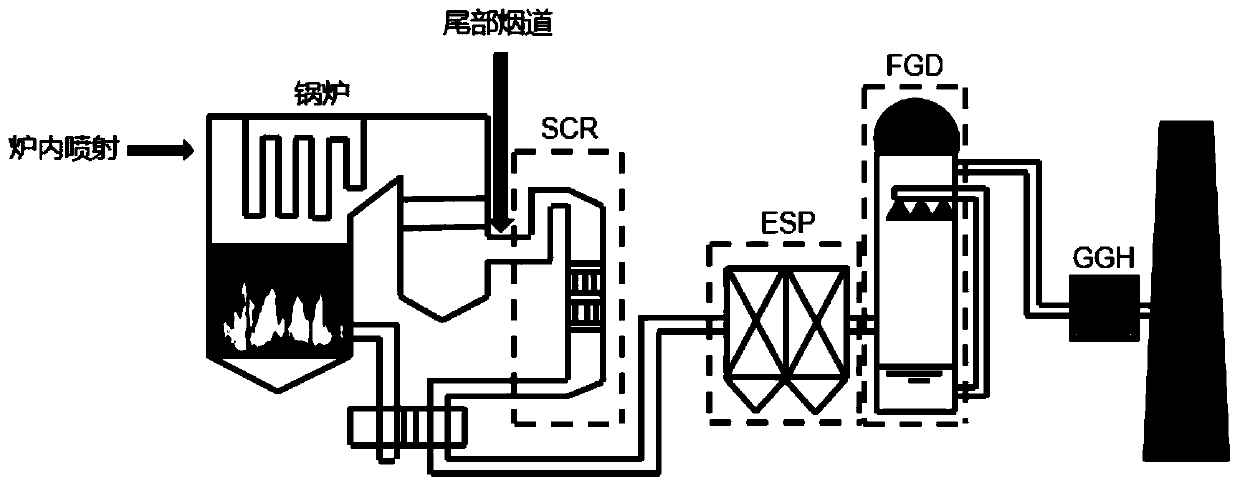

[0026] image 3 For the high-temperature flue gas treatment system of coal-fired power plants, the adsorbent of the present invention is sprayed into the furnace and the tail flue, so that it can be fully mixed with high-temperature coal-fired flue gas, and the arsenic oxide can be efficiently captured and ...

Embodiment 1

[0028] (1) Weigh 20g of waste sulfonated polystyrene resin, wash with deionized water, filter, place in a 40°C oven to dry for 4 hours, and seal it for later use;

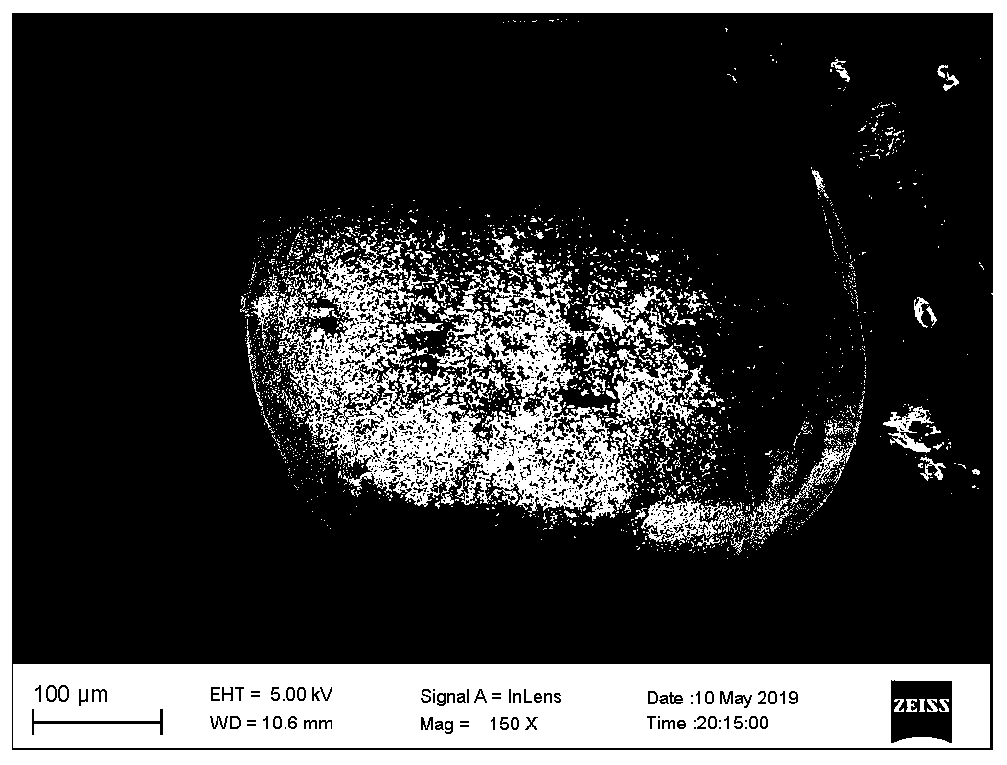

[0029] (2) Take spare resin 10g and join in 200ml iron-containing waste water, this iron-containing waste water comes from a certain iron and steel factory in Henan Province, the pH of the solution is 1, and the total iron content is about 2500mg / L; After magnetic stirring for 6 hours, filter out The resin was washed and dried, and then the resin was placed in a tube furnace and calcined at 500°C for 6 hours to obtain hollow iron oxide microspheres, the surface morphology of which was as follows: figure 2 , it can be seen that the particle size is 0.5 mm.

[0030] Take the prepared hollow iron oxide microspheres and 0.5 g of the purchased analytically pure calcium oxide, iron oxide and aluminum oxide, respectively, and place them in a high-temperature fixed-bed reactor, and raise the temperature to 600 °C and 1200...

Embodiment 2

[0033] (1) Weigh 20 g of waste sulfonated polystyrene resin, wash with deionized water, filter, place in a 50°C oven for 5 hours, and seal it for later use;

[0034](2) Weigh 3g of spare resin and add it to 100ml of iron-containing wastewater. The iron-containing wastewater comes from a steel plant in Henan Province. The pH of the solution is 1, and the total iron content is about 2500mg / L; after magnetic stirring for 8 hours, filter out The resin was washed and dried, and then the resin was placed in a tube furnace and calcined at 600° C. for 5 hours to obtain hollow iron oxide microspheres.

[0035] Take the prepared hollow iron oxide microspheres and 0.5 g of the purchased analytically pure calcium oxide, iron oxide and aluminum oxide, respectively, and place them in a high-temperature fixed-bed reactor, and raise the temperature to 600 °C and 1200 °C at a rate of 10 °C / min, respectively. , and then pass into the mixed gas phase As 2 o 3 The simulated coal flue gas (As 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com