Joint debugging operation control system and method based on garbage gasification coupling coal-fired power generation

A technology of operation control and gasification system, applied in the field of resource treatment, can solve problems such as coal-fired boiler operation impact, load fluctuation, etc., to achieve the effect of ensuring safety and stability, and increasing the number of operating hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

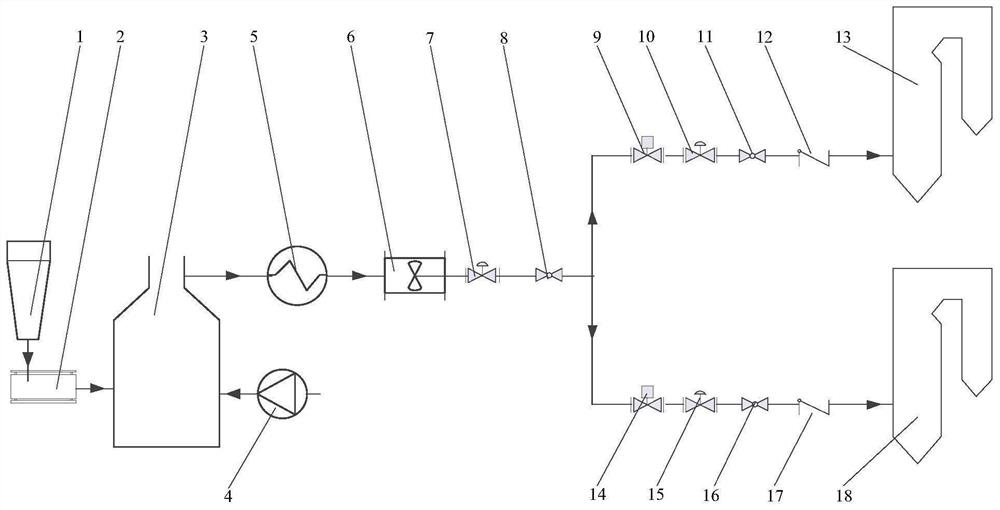

[0031] Embodiment 1 provides an integrated debugging operation control system based on waste gasification coupled with coal-fired power generation, including a waste gasification system and a coal-fired system coupled with gasification combustible gas.

[0032] The garbage gasification system includes a garbage bin 1, a feeder 2, a gasification furnace 3, a blower 4, a gas cooler 5, a gas induced draft fan 6, a first electric control valve 7 and a first stop valve 8, and the feeder The inlet of 2 is connected with the outlet of garbage bin 1, the outlet of feeder 2 is connected with the feeding inlet of gasifier 3, and the inlet of gasifier 3 is connected with the outlet of feeder 2 and the outlet of blower 4 respectively. The outlet of the chemical furnace 3 is connected to the gas inlet of the gas cooler 5, and the gas outlet of the gas cooler 5 is connected to the gasification combustible gas coupling combustion chamber through the gas induced draft fan 6, the first electric...

Embodiment 2

[0035]This embodiment 2 provides a control method based on the joint commissioning operation control system based on waste gasification coupled with coal-fired power generation. The waste gasification system gasifies waste at high temperature to generate gasified combustible gas, and then the gasified combustible gas is cooled by a gas cooler After reaching 400-500°C, the gas-fired induced draft fan is sent into the gasification combustible gas coupling coal-fired system through the pipeline, and finally enters the coal-fired boiler and pulverized coal for coupled combustion through various valves. The waste gasification system can realize the variable working condition adjustment of the gasification furnace operation through the frequency conversion adjustment means of the feeder and the blower, and at the same time, the first electric control valve can be used to realize the synchronous adjustment of the gasification combustible gas flow. During normal operation, the second s...

Embodiment 3

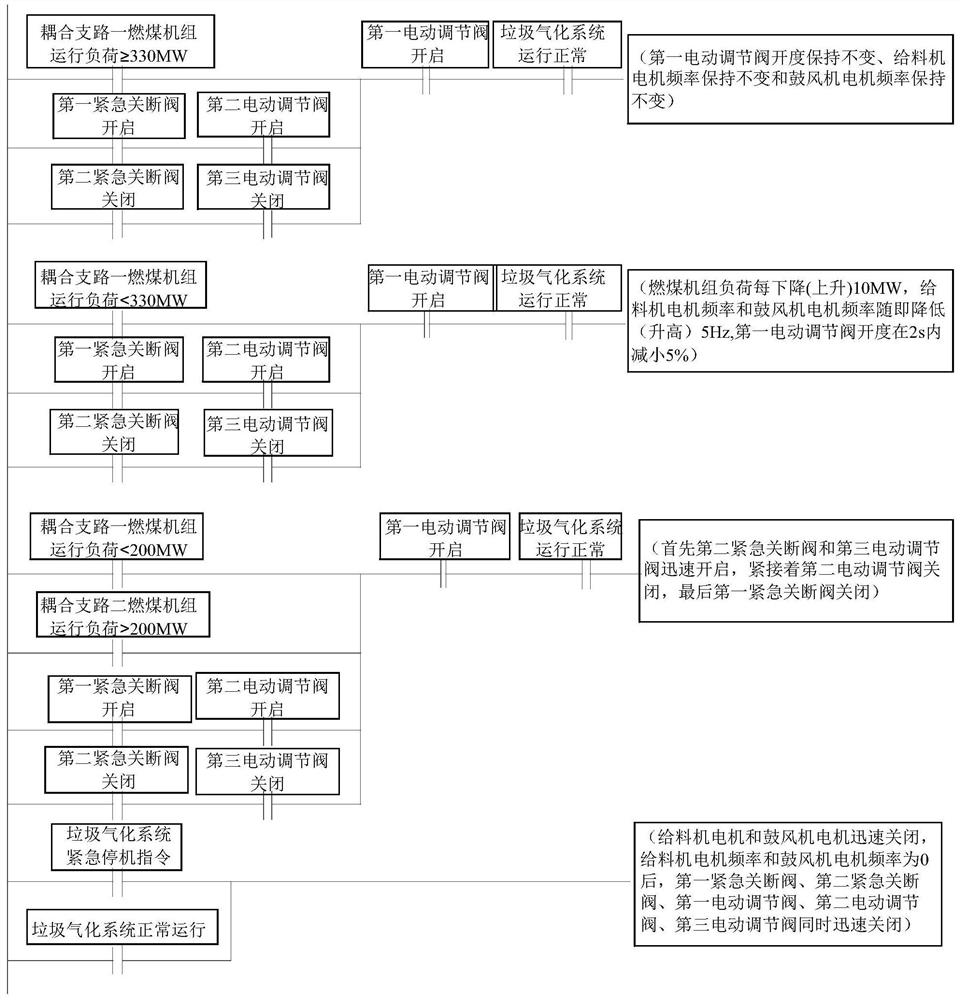

[0037] Embodiment 3 provides a control method for the joint commissioning operation control system based on waste gasification coupled with coal-fired power generation. When the following operating conditions occur in the joint commissioning operation control system based on waste gasification coupled with coal-fired power generation, the control system mainly adjusts as follows:

[0038] 1) When the coal-fired units in joint commissioning operation have frequent peak shaving, the backup coupling branch can be started at any time to balance the combustible gas, so as to ensure the normal and stable operation of the two coal-fired units and the garbage gasification system is always running in the best working condition. Once the coal-fired unit in joint debugging operation has frequent peak regulation problems, it can be started by operating the second emergency shut-off valve 14 (or the first emergency shut-off valve 9), the third electric regulating valve 15 (or the second ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com