Cold-end waste heat gradient-utilization energy-saving system and method

An energy-saving system and thermal system technology, which is applied in the field of waste heat utilization energy-saving system at the cold end, can solve the problems of reducing the economy of waste heat utilization devices and failure of waste heat recovery devices to be put into operation, and achieve the effect of increasing operating hours and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

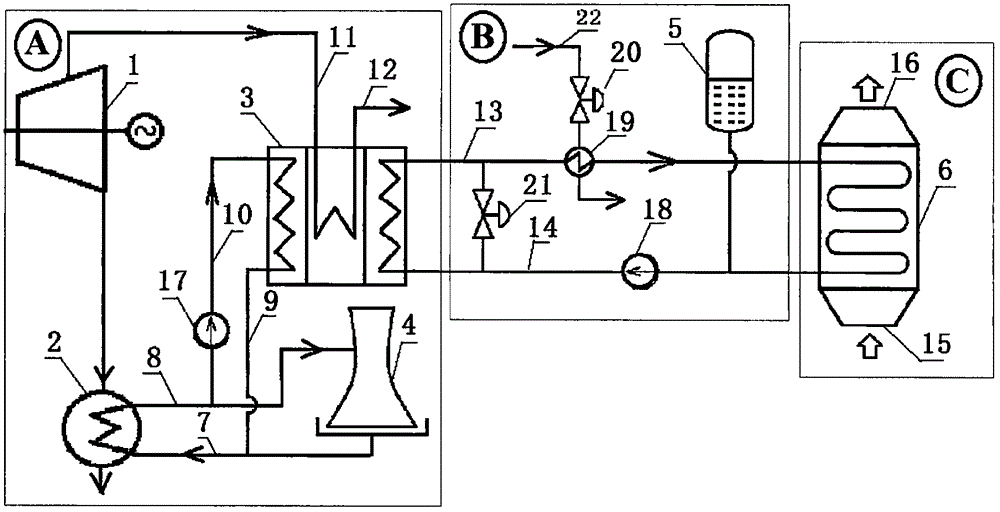

[0015] Attached below figure 1 To further describe the present invention, it should be understood that the content described here is only for illustrating and explaining the present invention, and is not intended to limit the present invention.

[0016] The energy-saving system for cascade utilization of waste heat at the cold end of the present invention includes three systems: A heat extraction system, B heat medium control system, and C heating system;

[0017] Heat extraction system includes steam turbine 1, condenser 2, heat pump unit 3; heating system includes boiler primary air or secondary air system, boiler primary air or secondary air heating system; heat medium control (water medium) system includes closed cycle Intermediate water (water media), pipelines, valves, heating steam system, water supply system, constant pressure system, sewage system, etc.

[0018] 1. Heat extraction system

[0019] The heat extraction system includes a steam turbine 1 , a condenser 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com