Chemical fiber elastic double-sided cloth with full spandex on one side and preparation method thereof

A technology of all-spandex and double-sided cloth, which is applied in the textile field and can solve problems such as resistance to oxidation, difficulty in realization, and poor hygroscopicity of spandex.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

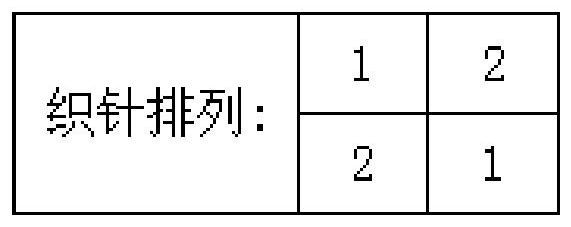

[0053] Weaving raw materials and quantity:

[0054] PA6 40D / 34F DTY or polyester 24pcs

[0055] PU 40D 48 pcs

[0056] PU 20D 24 pcs.

[0057] The raw material composition of embodiment 1-4 is as shown in table 1:

[0058] Table 1.

[0059]

[0060]"PA6 40D / 34F SD DTY" means semi-dull stretch textured nylon 6 with a thickness of 40D and a hole number of 34F.

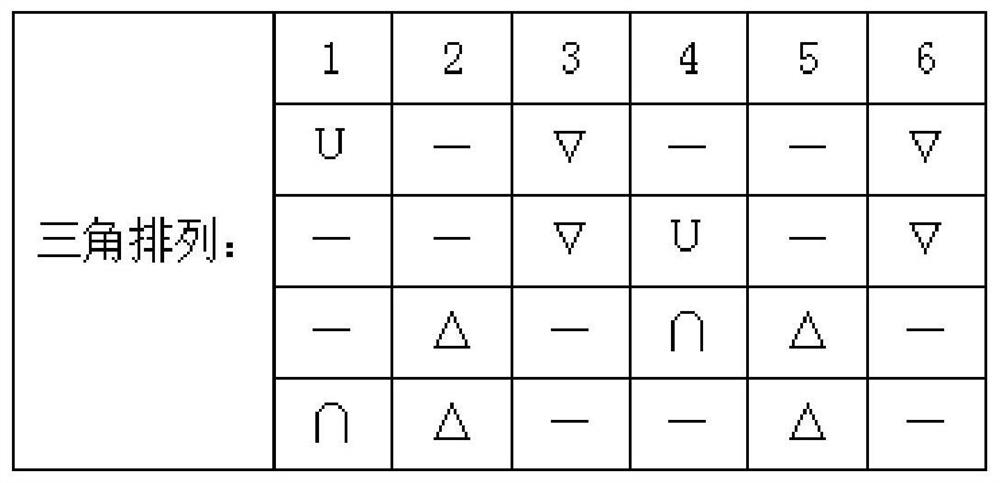

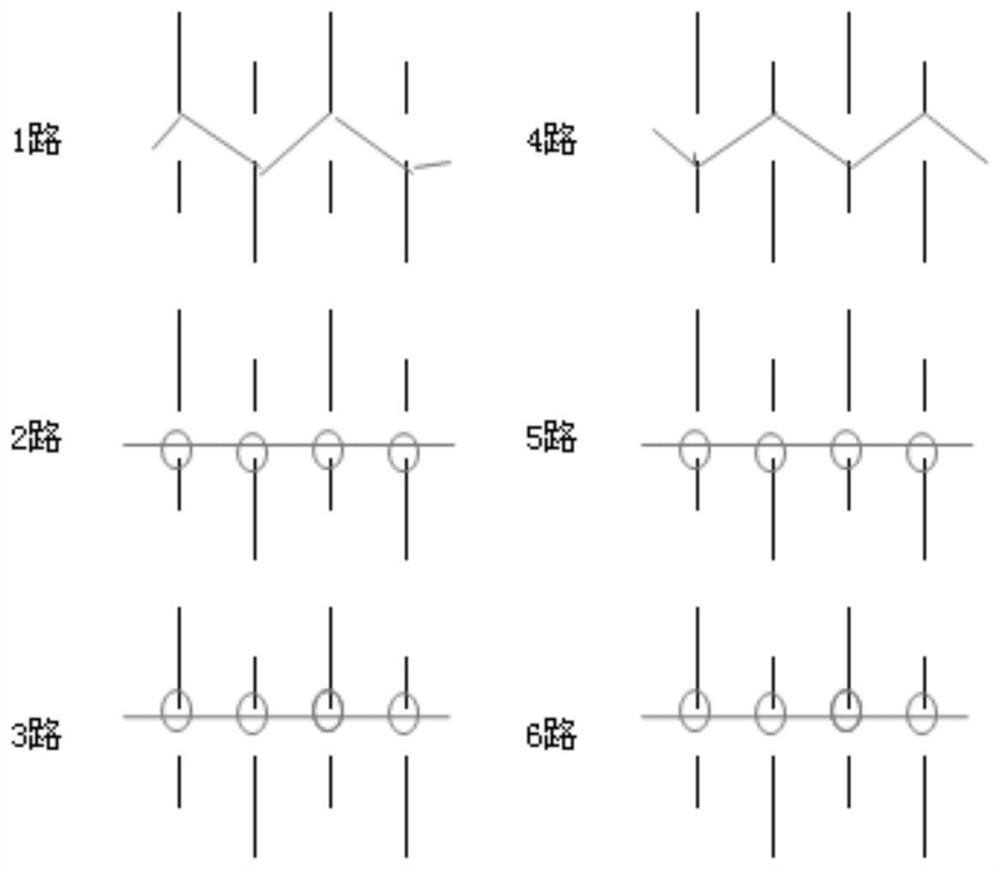

[0061] Embodiment 1-4 is all prepared according to the following method:

[0062] The double-sided circular knitting machine is used for weaving, and the inner diameter of the two conveying discs of the double-sided circular knitting machine is adjusted, and the yarn storage device is driven by the conveying belt to provide the corresponding incoming line speed, and the corresponding incoming yarn is introduced into each loop. Long, and keep the tension of each thread of the same raw material consistent, the raw yarn is introduced into the knitting loop area through the yarn feeder to be woven into a loop and for...

Embodiment 5-6

[0071] Embodiment 5-6, comparative example 1-6

[0072] Examples 5-6 and Comparative Examples 1-6 have the same raw material composition as Example 4, and the different process parameters in the preparation process are shown in Table 2, and the rest are the same.

[0073] Table 2.

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com