Single-side road edge concrete pouring and paving equipment for municipal road construction

A municipal road and concrete technology, which is applied in the field of single-side roadside concrete pouring and paving equipment for municipal road construction, can solve the problems of cumbersome operation, more manpower consumption, uneven laying, etc. The effect of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

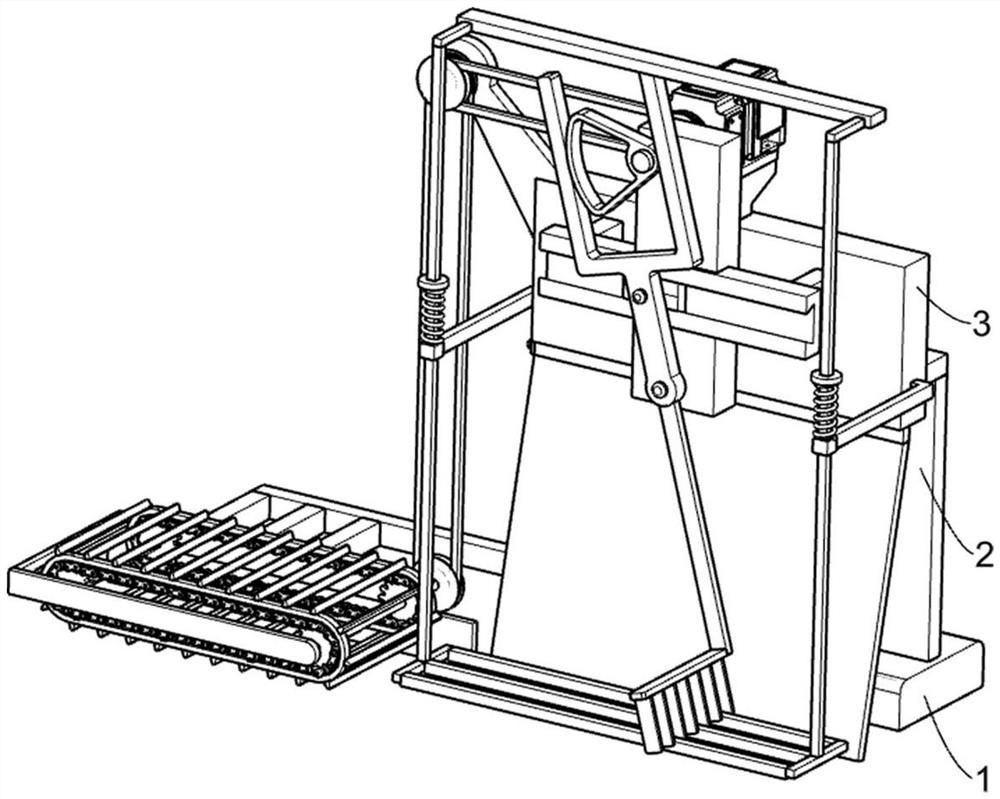

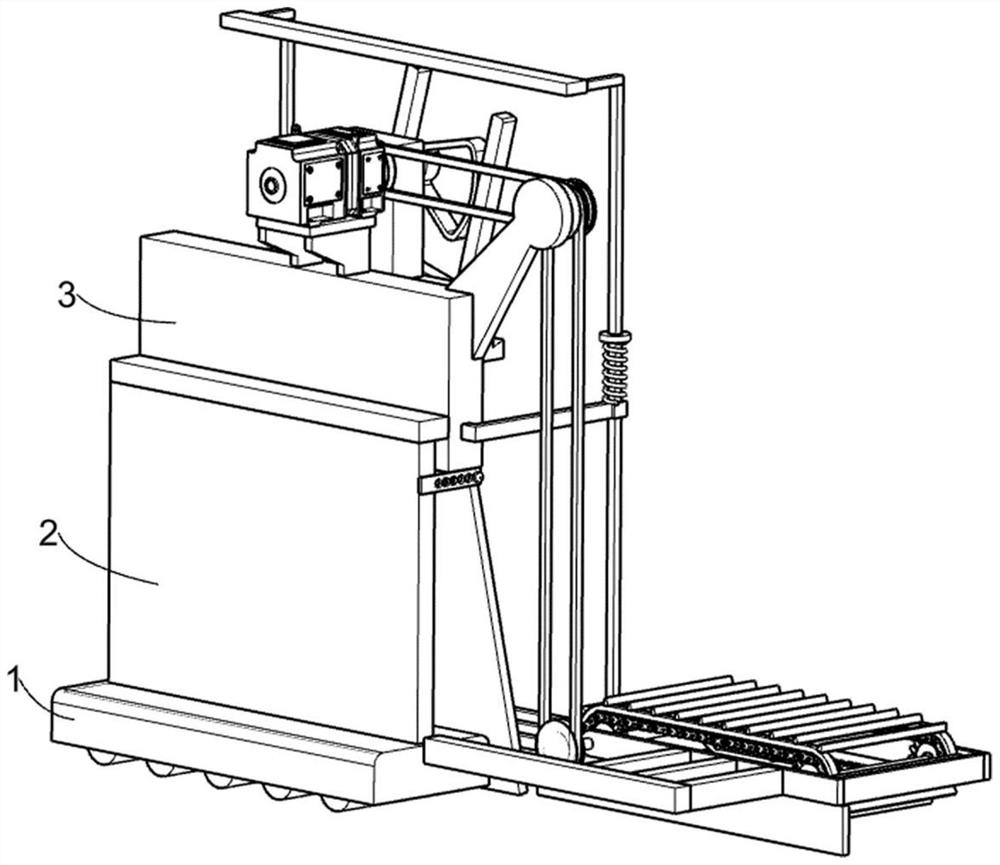

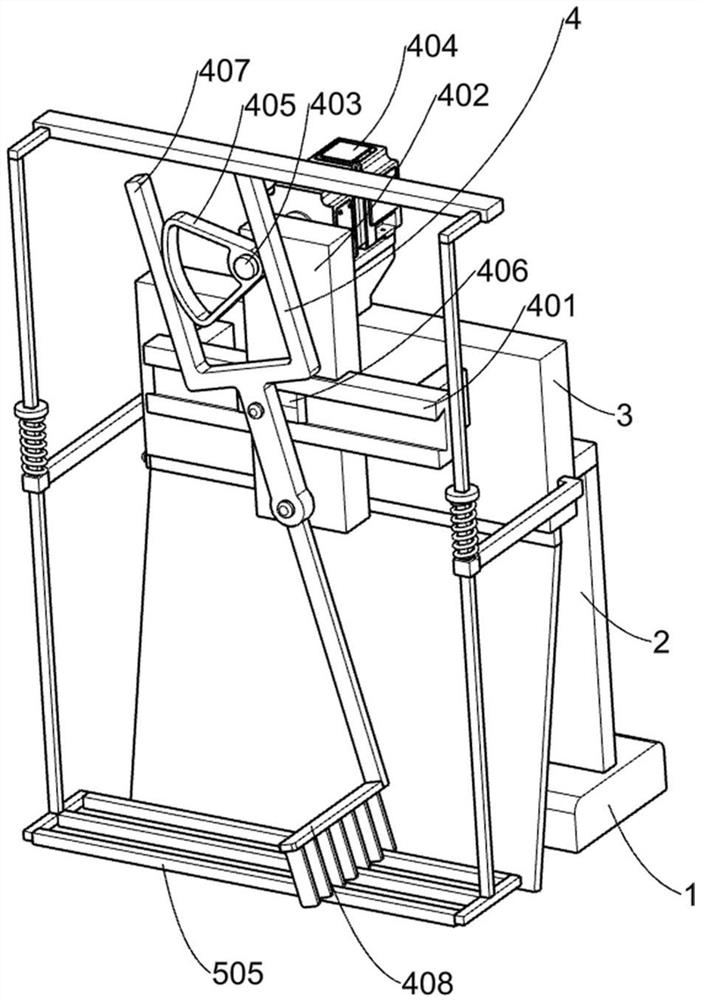

[0021] A kind of single-side roadside concrete pouring and paving equipment for municipal road construction, such as Figure 1-7 As shown, it includes a wheel base 1, a support plate 2, a mounting plate 3, a concrete leveling mechanism 4, a concrete dispersion mechanism 5 and a concrete spreading distance adjustment mechanism 6, and the support plate 2 is fixed on the upper side of the wheel base 1 , the mounting plate 3 is fixed on the upper end of the support plate 2, the concrete leveling mechanism 4 for leveling the concrete is set on the mounting plate 3, and the concrete that is piled up in one place is dispersed to two The side concrete spreading mechanism 5 is arranged on the mounting plate 3 and is connected with the concrete leveling mechanism 4 , and the concrete laying distance adjusting mechanism 6 for controlling the width of concrete pouring is arranged on the supporting plate 2 and the mounting plate 3 .

[0022] The concrete leveling mechanism 4 includes a gui...

Embodiment 2

[0028] On the basis of Example 1, such as Figure 7 As shown, it also includes a concrete paving mechanism 7 that can make the poured concrete lay evenly. The concrete paving mechanism 7 is arranged on the wheel base 1 and the mounting plate 3 and is connected with the concrete bulldozing mechanism 4. The concrete paving mechanism 7 comprises a support frame 701, a support frame 702, a first drive shaft 703, a second drive shaft 704, a sprocket wheel 705, a chain 706, a conveyor belt 707, a flat bar 708, a first pulley 709, a support seat 7010, Double groove pulley 7011, the first flat belt 7012, the second pulley 7013 and the second flat belt 7014, the support frame 701 is fixed on one end of the wheel base 1 and is close to the support plate 2, the support frame 702 is fixed On the support frame 701, the first drive shaft 703 is arranged on one end of the support frame 702 through a bearing, and the second drive shaft 704 is arranged on the other end of the support frame 702...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap