Supersonic wave technology-based hollow fiber film preparation method

An ultrasonic and fiber membrane technology, applied in the field of hollow fiber membrane preparation, can solve the problems of few researches on the membrane preparation process, achieve high practical application value, improve the pore structure, promote the effect of pore formation and pore preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

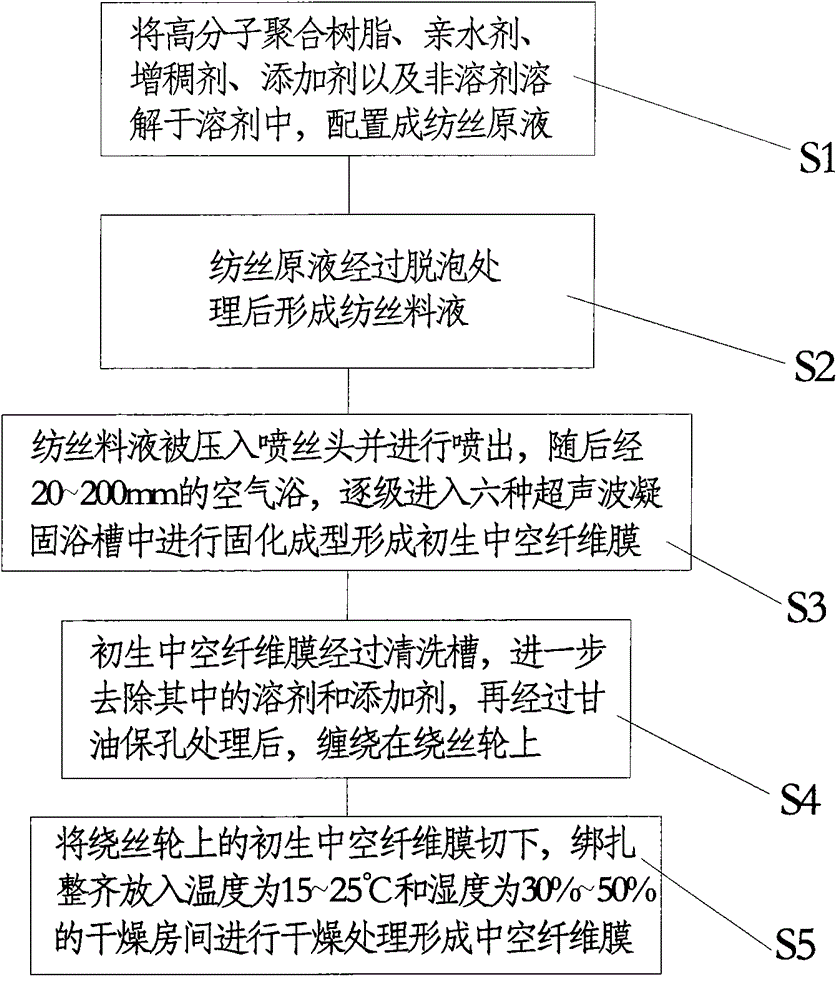

[0021] like figure 1 Shown: a method for preparing a hollow fiber membrane based on ultrasonic technology according to an embodiment of the present invention, the steps of which include: S1: preparing a spinning stock solution, dissolving a polymer resin, a hydrophilic agent, a thickener, an additive, and a non-solvent In a solvent, it is prepared into a spinning stock solution; S2: The spinning stock solution is degassed to make a spinning stock solution; S3: The spinning stock solution is pressed into the spinneret to be sprayed out, and then passed through a 20-200mm air bath Step by step, enter the first-level ultrasonic coagulation bath, the second-level ultrasonic coagulation bath, the third-level ultrasonic coagulation bath, the fourth-level ultrasonic coagulation bath, the fifth-level ultrasonic coagulation bath and the sixth-level ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com