Fabricated board room and building method thereof

A prefabricated, prefabricated house technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems of poor sound insulation, etc., to achieve the effect of reducing noise, convenient installation, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

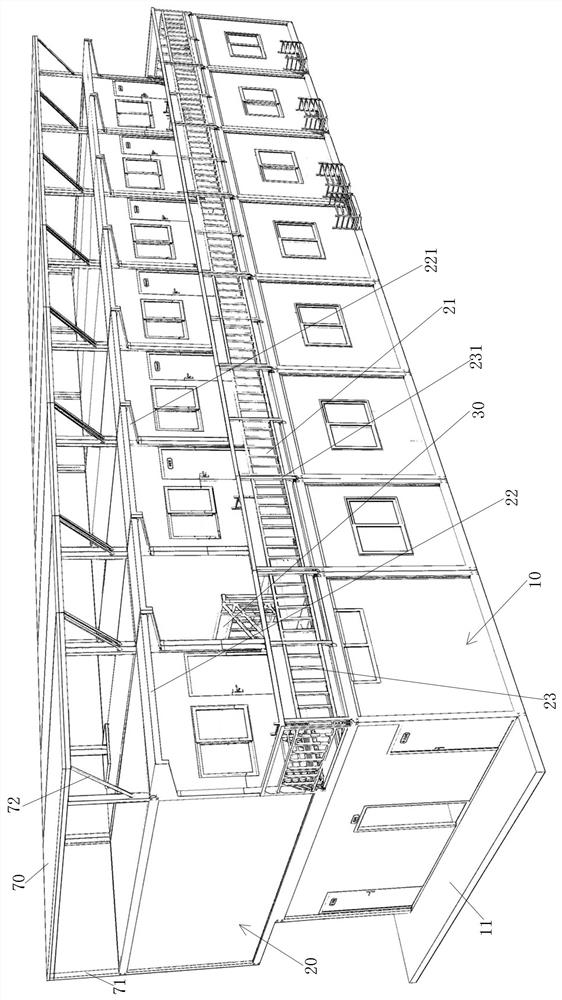

[0038] A prefabricated board room, please refer to Figure 1 to Figure 7 .

[0039] Such as figure 1 As shown, the prefabricated prefabricated house provided by the embodiment of the present invention includes the first floor 10 of the prefabricated house, the second floor 20 of the prefabricated house and the stairs 30, the stairs 30 extend from the first floor 10 of the prefabricated house to the second floor 20 of the prefabricated house, and the first floor 10 Both the second floor 20 of the board room include several box rooms arranged side by side, and the second floor 20 of the board room is installed on the first floor 10 top of the board room. The second floor 20 of the prefabricated house is arranged in a forward dislocation relative to the first floor 10 of the prefabricated house, and the part of the rear side of the top surface of the first floor 10 of the prefabricated house is used as the second-floor corridor 21, and the doors of each box room in the second fl...

Embodiment 2

[0057] A method of building a prefabricated board room, please refer to Figure 7 .

[0058] The construction method of the prefabricated prefabricated house in the embodiment of the present invention includes:

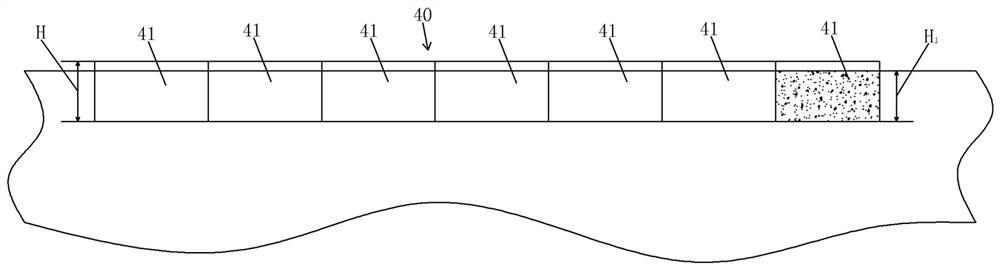

[0059] S100: Laying the foundation of the prefabricated house: dig a foundation pit on the ground where the prefabricated house needs to be built and level it, and use prefabricated concrete slabs to assemble the foundation of the prefabricated house at the foundation pit. The thickness of the concrete slab is not less than 500mm. Buried in the ground, and the burial depth of the board house foundation is not less than 500mm, and a number of studs for fixing the box house are pre-embedded in each concrete slab.

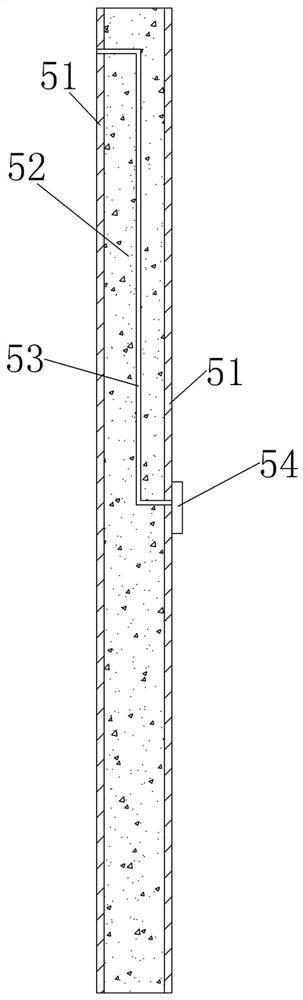

[0060] S200: Assembling container houses: Use pre-prepared channel steel, angle steel and other steel materials and connecting bolts to assemble the frame of the container house. During the process of assembling the frame, install the wall, floor and roof bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com