Assembly type wallboard component cast-in-place combined wall body

A prefabricated, wall panel technology, applied in the direction of building components, walls, building structures, etc., can solve the problems of loose building components, lack of mutual restraint measures, insufficient overall stability of prefabricated composite walls, etc., to improve waterproofness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

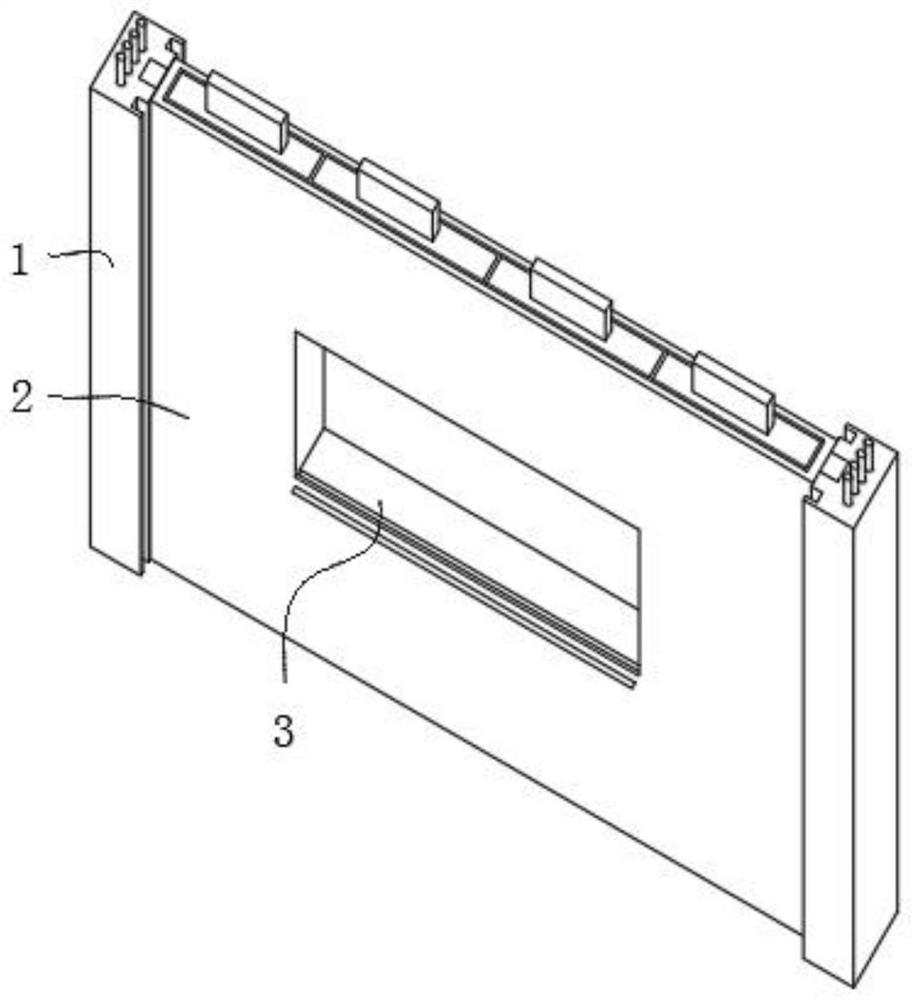

[0035] Such as figure 1 , figure 2 and Figure 4 As shown, a prefabricated wall panel component cast-in-place combined wall, including pouring beams 2:

[0036] The interior of the pouring beam 2 is poured with a steel bar frame 22 along its length, which is used to strengthen and support the pouring beam 2 and improve the self-strength of the pouring beam 2;

[0037] The top of the pouring beam body 2 and the reinforcing ribs 21 are poured at the intervals between the reinforcement frames 22, so as to facilitate positioning, assembly and connection of the top of the pouring beam body 2 with other building components;

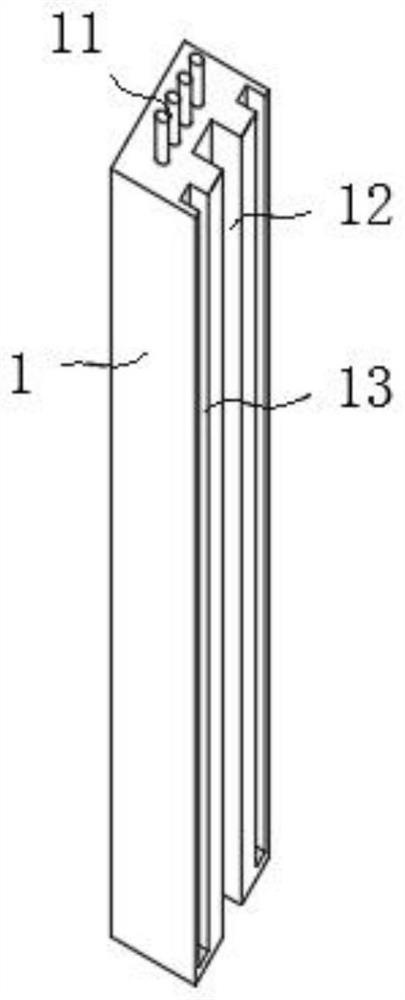

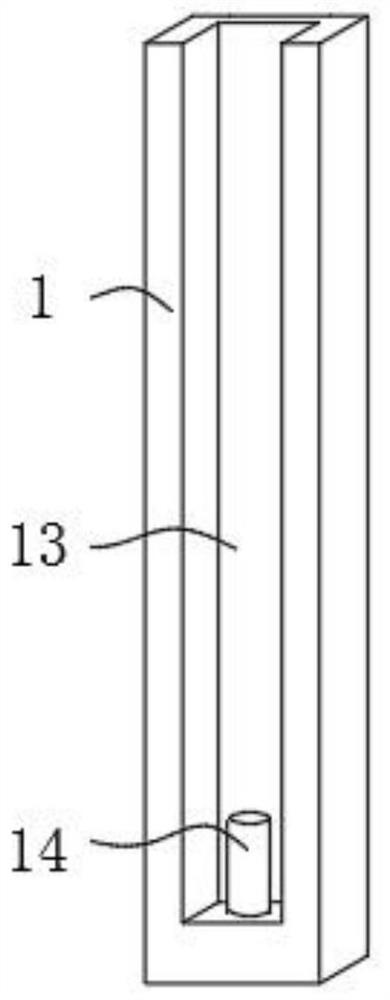

[0038] It also includes uprights 1, the num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com