Cloth cover pre-inspection mechanism, cloth inspection device comprising same and cloth inspection method

A cloth surface and pre-inspection technology, applied in the direction of measuring devices, organic chemistry, instruments, etc., can solve the problems of inconvenient addition of intelligent visual cloth inspection equipment to the cloth inspection machine, and the light source cannot meet the camera requirements, etc., to achieve both adaptability and economy Sex, reduce the damage of human eyes, improve the effect of shooting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

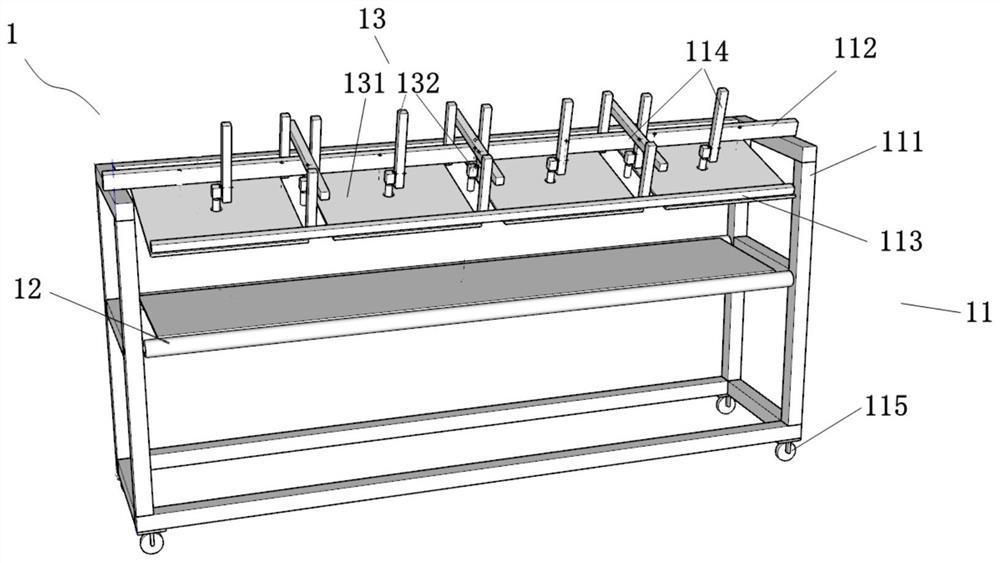

[0057] The present embodiment provides a cloth surface pre-check mechanism 1, such as figure 1 As shown, it includes a pre-check frame 11 , a pre-check roller assembly 12 and a photoelectric assembly 13 . The pre-inspection roller assembly 12 is arranged on the pre-inspection frame 11 for flattening the cloth; the photoelectric assembly 13 is arranged toward the cloth for inspecting whether there is any defect on the cloth surface.

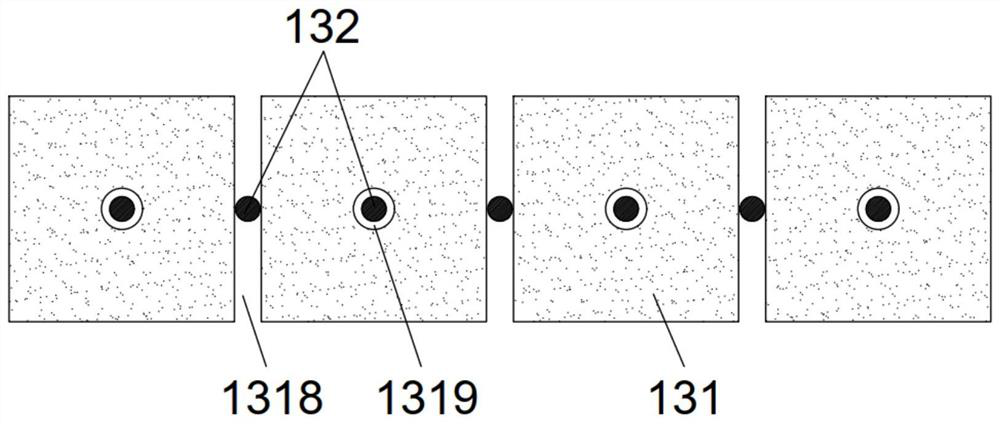

[0058] Such as figure 1 As shown, the photoelectric component 13 includes at least one surface light source 131 and at least one camera 132. The surface light source 131 illuminates the surface of the cloth, and the camera 132 takes pictures of the cloth and transmits them to the terminal. Such as figure 2 As shown, the surface light source 131 is a rectangular surface light source with a light-emitting surface of (40-60)×(40-60) cm, which can provide uniform light and has a large irradiation area.

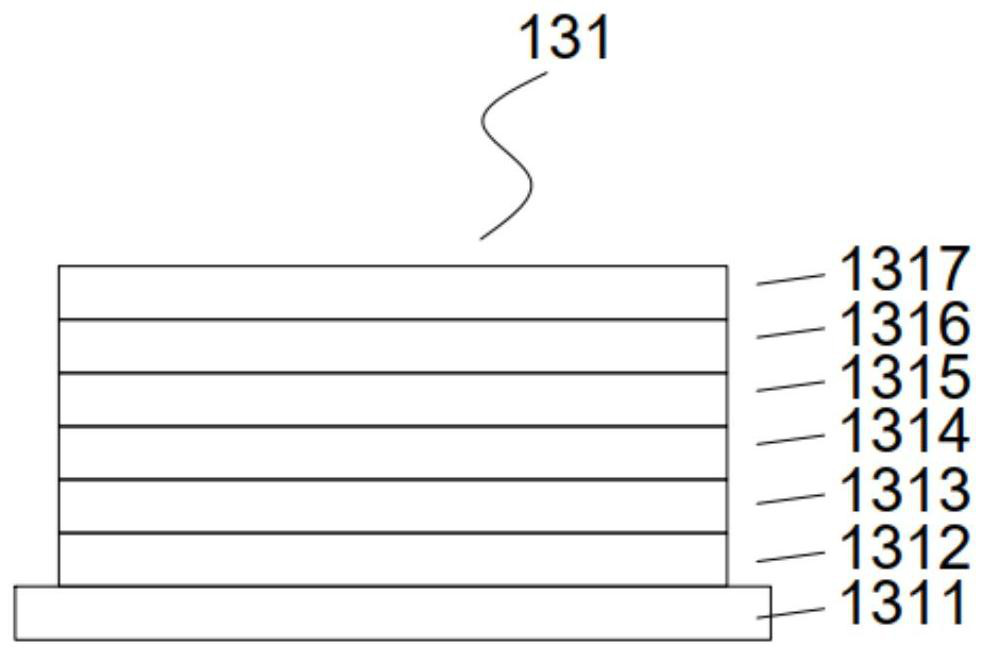

[0059] Such as image 3 As shown, the surf...

Embodiment 2

[0081] This embodiment provides a cloth inspection device, such as Figure 10 As shown, the cloth surface pre-inspection mechanism 1, the unwinding mechanism 2 and the cloth inspection mechanism 3 of the embodiment 1 are included.

[0082] The unwinding mechanism 2 is arranged upstream of the cloth surface pre-inspection mechanism 1, and is used to roll the cloth to be inspected;

[0083] The pre-inspection cloth roller 121 of the cloth surface pre-inspection mechanism 1 is provided with four, and every two pre-inspection cloth rollers 121 are a group and are arranged side by side on the pre-inspection roller frame 122, and this pre-inspection roller frame 122 and the pre-inspection frame 111 can be Turn to connect. The cloth passes around four pre-inspection cloth rollers 121 successively by the unwinding mechanism 2S type to form an inspection plane.

[0084] The cloth inspection mechanism 3 is a conventional cloth inspection device, including a cloth inspection frame 31 ,...

Embodiment 3

[0087] This embodiment provides a cloth inspection method, comprising the following steps:

[0088]S1. Unwind the cloth to be inspected through the unwinding mechanism 2, and then realize the flattening of the cloth by the cloth surface pre-inspection mechanism 1 and the cloth inspection mechanism 3 in sequence. By adjusting the pre-inspection frame 111, adjusting each light source bracket 113 and each camera The bracket 114 realizes the height difference and angle adjustment between the cloth and the surface light source 131;

[0089] S2. Adjust the refractive index of the wavelength electric control layer 1313 by voltage, and then adjust the wavelength of the light to further improve the irradiation effect of the light on the cloth;

[0090] S3. Start the winding assembly 33 , drive the cloth through the winding assembly 33 to pass through the area irradiated by the surface light source 131 sequentially, and obtain the cloth surface condition through the camera 132 , and sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com