Gas relay calibration device

A technology of calibration device and relay, which is applied in the direction of circuit breaker testing, etc., can solve the problem of polluting the calibration table and achieve an intuitive demonstration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

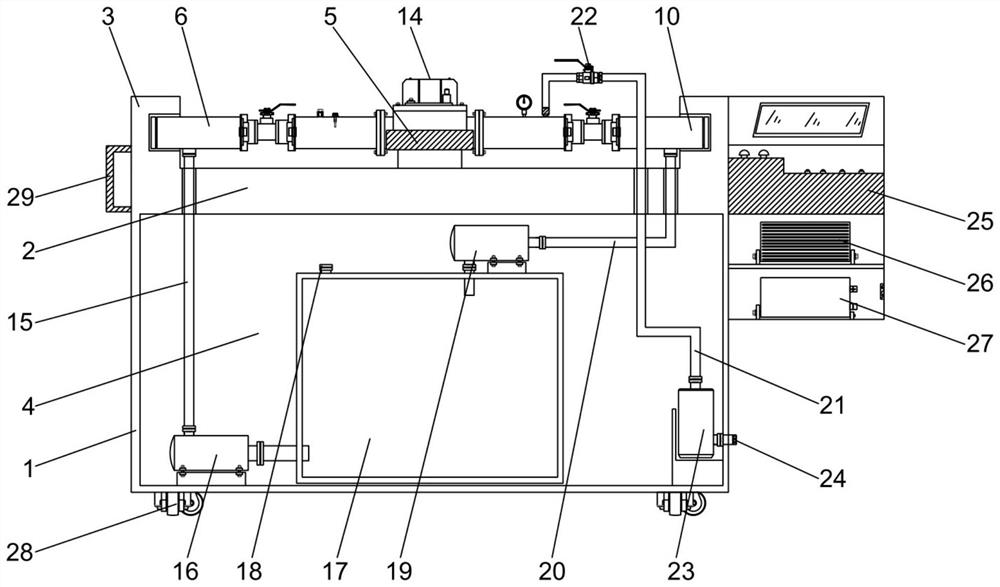

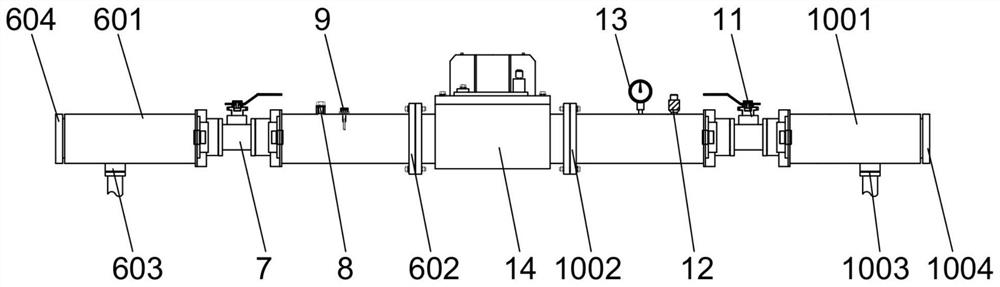

[0024] Embodiment 1: Buchholz relay calibration device, such as figure 1 As shown, it includes a box body 1, the top of the box body 1 is fixedly provided with a workbench 2, the left and right ends of the workbench 2 are fixedly provided with vertical fixing seats 3, and the middle part of the workbench 2 is provided with a place for placing the gas relay 14. The deck 5 includes a two-jaw chuck and a cylinder providing power for the two-jaw chuck, and the two-jaw chuck is fixed on the workbench. Such as figure 1 with figure 2 As shown, the left side of the card seat 5 is provided with an oil delivery test pipeline I6, and the oil delivery test pipeline I6 includes a hard transparent tube I601 that is transparent on the left and right, and the right end of the hard transparent tube I601 is fixedly connected with a flange piece I602. The left end of the transparent tube I601 is provided with a screw-connected plug I604, and the fixed seat 3 on the left side is provided with ...

Embodiment 2

[0031] Embodiment 2: Buchholz relay calibration device, the oil tank 17 is set as a fully sealed box structure, further reducing the possibility of oil leakage of the device. Other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com