Spline function-based external parameter calibration method for 3D laser radar and inertial sensor at continuous time

A technology of inertial sensor and calibration method, which is applied in the field of multi-sensor calibration, 3D lidar and inertial sensor external parameter calibration, and can solve the problems that linear interpolation cannot be applied and the assumption of uniform velocity cannot be established.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited to the specific implementation.

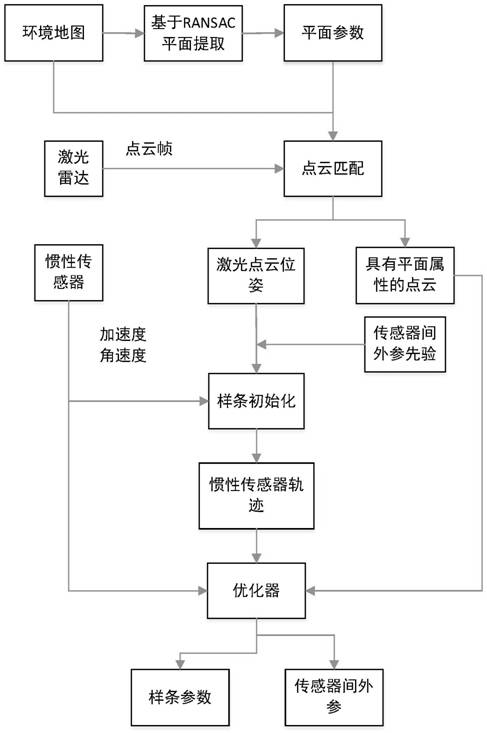

[0040] figure 1 It is a flowchart of a continuous-time 3D laser radar and inertial sensor external parameter calibration system based on a spline function, including five steps of the previous processing flow.

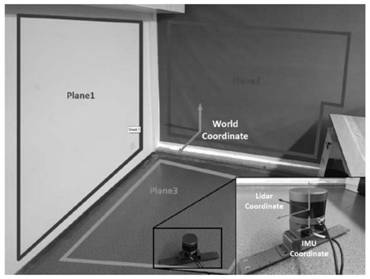

[0041] Calibration environment such as figure 2 shown. The environmental map is known, and it can be obtained by using the single-line laser radar plus stepping motor solution described in the present invention, and can also be obtained by other mapping methods. Based on the RANSAC plane extraction method, extract three plane point clouds P of the wall corner in the known environment map i (i=0,1,2), and calculate and fit 3 plane point clouds to get the plane parameters, which are the normal vector n i and the plane distance w from the origin i . The re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com